Method for efficiently and mildly reducing ovalbumin allergenicity

An ovalbumin and allergenic technology, applied in animal protein processing, protein food ingredients, protein food processing and other directions, can solve the problem of quality decline of egg products, reduce allergenicity, improve pertinence and effectiveness, reduce small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Ovalbumin extraction: separate the egg white from the egg yolk with an egg separator, add 1 volume of 50 mmol / L NaCl solution to the egg white, mix and stir for 2 hours, adjust the pH to 6.0; add 10% (w / w ) with PEG-8000, magnetically stirred for 2 hours; centrifuged at 4°C and 15,000g for 10 minutes, and collected the supernatant; dialyzed the collected liquid with deionized water for 4 times at 4°C, and freeze-dried to obtain ovalbumin;

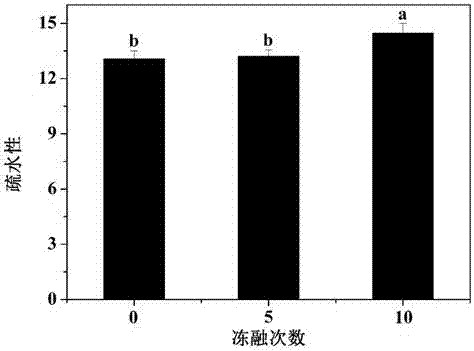

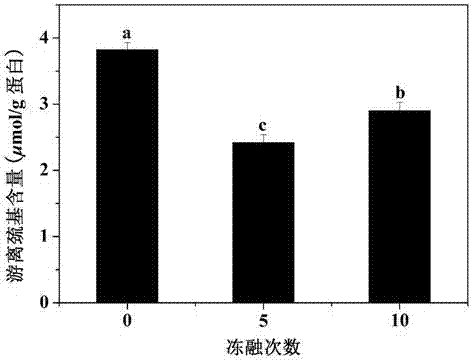

[0040] (2) Repeated freeze-thaw treatment: redissolve ovalbumin obtained in step (1) in deionized water according to its proportion in natural egg white (5.4%), freeze at -20°C for 12 h, and then thaw at 20°C for 12 h. h, after repeating 3 times, finally freeze-dry to obtain protein samples;

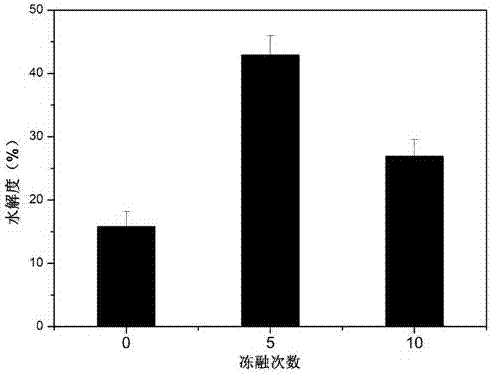

[0041] (3) Enzyme treatment: add the ovalbumin treated in step (2) to a transglycosylase at a ratio of 1:200 (wt / wt, enzyme: protein), and treat for 2 hours at pH 8.0 and temperature 25°C. After that, trypsin was added at a ratio of 1:200 (w...

Embodiment 2

[0043] (1) Ovalbumin extraction: Separate the egg white from the egg yolk with an egg separator, add 8 times the volume of 50 mmol / L NaCl solution to the egg white, mix and stir for 2 hours, adjust the pH to 6.0; add 50% (w / w ) with PEG-8000, magnetically stirred for 2 hours; centrifuged at 4°C and 15,000g for 10 minutes to collect the supernatant; dialyzed the collected liquid with deionized water four times at 4°C, and freeze-dried to obtain ovalbumin;

[0044] (2) Repeated freeze-thaw treatment: redissolve ovalbumin obtained in step (1) in deionized water according to its proportion in natural egg white (5.4%), freeze at -20°C for 12 h, and then thaw at 20°C for 12 h. h, after repeating 7 times, finally freeze-dry to obtain the protein sample;

[0045] (3) Enzyme treatment: add the ovalbumin treated in step (2) to a transglycosylase at a ratio of 1:200 (wt / wt, enzyme: protein), and treat for 2 hours at pH 8.0 and temperature 25°C. After that, trypsin was added at a ratio o...

Embodiment 3

[0047] (1) Ovalbumin extraction: Separate the egg white from the egg yolk with an egg separator, add 3 times the volume of 50 mmol / L NaCl solution to the egg white, mix and stir for 2 hours, adjust the pH to 6.0; add 15% (w / w ) with PEG-8000, magnetically stirred for 2 hours; centrifuged at 4°C and 15,000g for 10 minutes to collect the supernatant; dialyzed the collected liquid with deionized water four times at 4°C, and freeze-dried to obtain ovalbumin;

[0048] (2) Repeated freeze-thaw treatment: redissolve ovalbumin obtained in step (1) in deionized water according to its proportion in natural egg white (5.4%), freeze at -20°C for 12 h, and then thaw at 20°C for 12 h. h, after repeating 5 times respectively, finally freeze-dry to obtain the protein sample;

[0049] (3) Enzyme treatment: add the ovalbumin treated in step (2) to a transglycosylase at a ratio of 1:200 (wt / wt, enzyme: protein), and treat for 2 hours at pH 8.0 and temperature 25°C. After that, trypsin was added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com