Preparation method of spongy porous silicon-dioxide nanosheet

A technology of porous silica and silica, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation methods and toxicity, achieve simple and controllable processes, enhance physical bonding, and achieve sustainable development. Unleash the effect of behavior improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

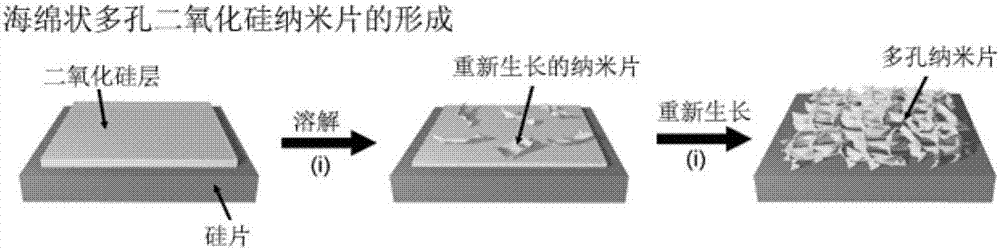

[0031] see figure 1 As shown, the preparation method of the spongy porous silicon dioxide nanosheet of the present invention comprises the following steps: 1) preparing a silicon dioxide film on a silicon wafer to obtain a silicon wafer with a silicon dioxide film.

[0032] In step 1), a silicon dioxide film is prepared on a silicon wafer by magnetron sputtering. Using magnetron sputtering to prepare a silicon dioxide film on a silicon wafer, the thickness of the prepared silicon dioxide film is more controllable and more uniform.

[0033] In step 1), preparing silicon dioxide film on silicon wafer by magnetron sputtering method comprises the following steps:

[0034] 1. Take a silicon wafer polished on one side and clean it; wherein, the crystal orientation of the silicon wafer is [001].

[0035] 2. Using a silicon dioxide target to perform magnetron sputtering to obtain a silicon wafer with a silicon dioxide film. Preferably, the purity of the silicon dioxide target is gr...

Embodiment 1

[0043] Step 1: Prepare SiO with a thickness of 200 nm on a silicon (Si) wafer by magnetron sputtering 2 film. Specifically include the following steps:

[0044] Step 1.1: Take a Si wafer with a diameter of 6 inches and a crystal orientation of (001) polished on one side, clean it, and spin dry it.

[0045] Step 1.2: Use 99.99% pure SiO 2 The target is sputtered in an argon atmosphere to obtain SiO 2 film.

[0046] Step 1.3: For convenience, the surface was sputtered with SiO 2The silicon wafer of the thin film is cut into small pieces of 2cm×2cm for later use.

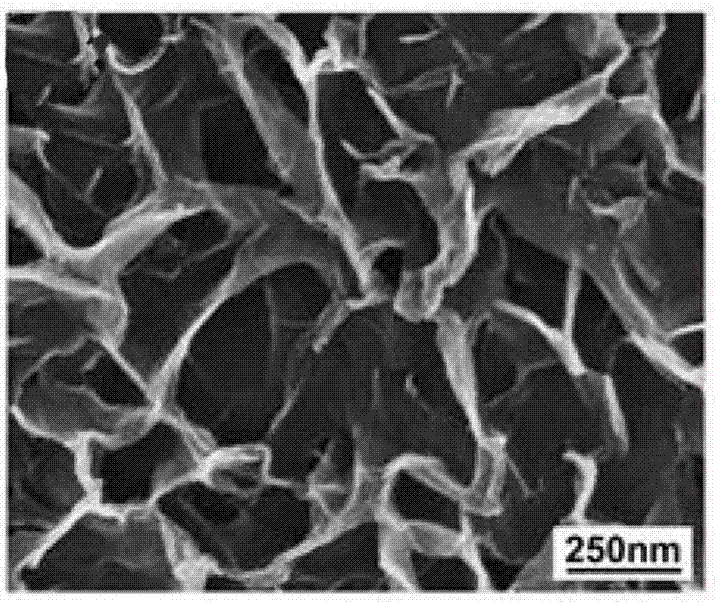

[0047] Step 2: Preparation of sponge-like porous SiO using hydrothermal method 2 Nanosheets. Specifically include the following steps:

[0048] Step 2.1: Prepare NaBH with a concentration of 0.1g / ml 4 solution.

[0049] Step 2.2: Take 2ml NaBH 4 The solution was placed in a steel autoclave lined with polytetrafluoroethylene with a capacity of 20ml, and the cut pieces were immersed in it, and allowed to react...

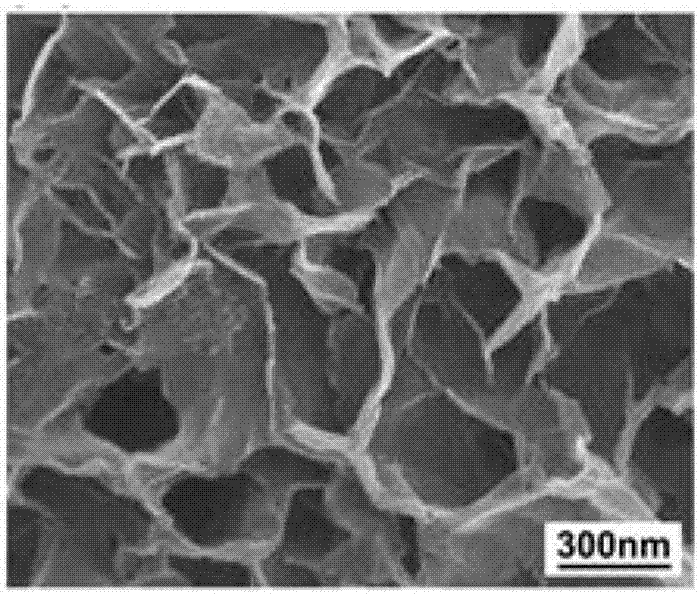

Embodiment 2

[0053] Similar to Example 1, the difference is that the NaBH in the step 2.1 of Example 1 4 The concentration of the solution was changed to 1g / ml, and the reaction time was 2h. Other conditions remained the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com