A magnetic ore dry separation grading vibrating screen

A vibrating screen and mine drying technology, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of increasing the construction cost of the screening room, increasing the load of the screening equipment, and high demand for the height difference between the screening rooms. Achieve the effect of saving engineering construction costs, avoiding restrictions on the angle of the feeding hopper, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

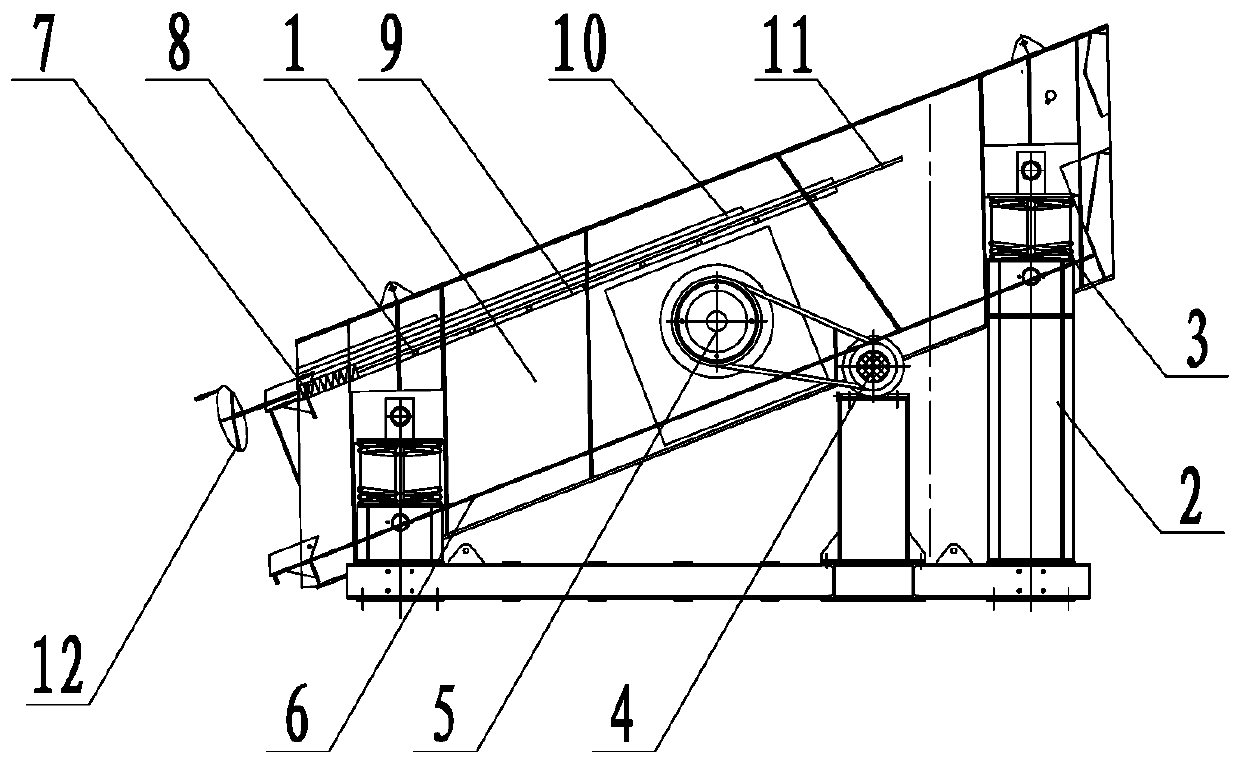

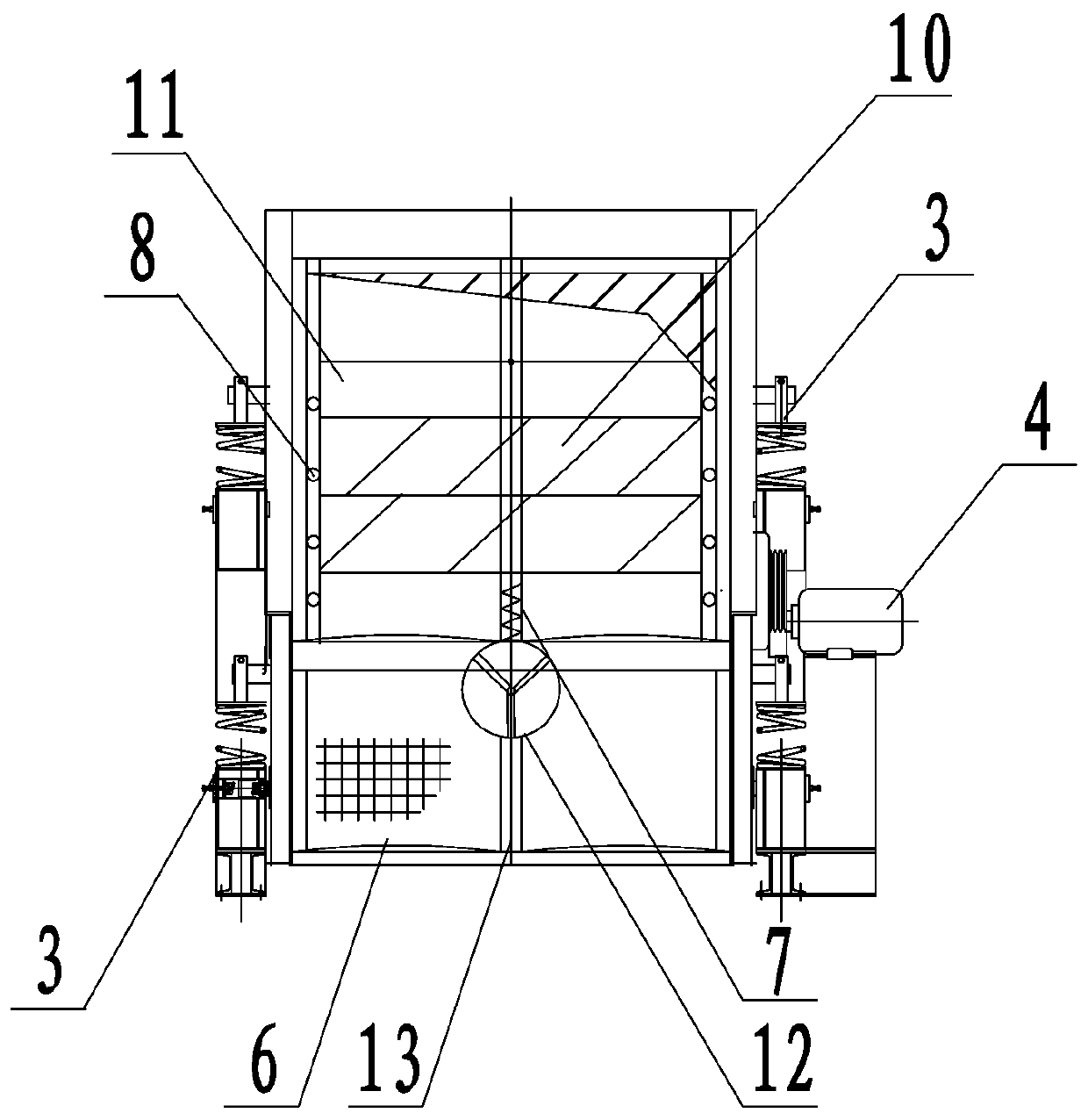

[0017] Such as figure 1 with figure 2 As shown, a kind of magnetic ore dry separation grading vibrating screen of the present invention comprises screen box 1, sieve plate 6, support 2, vibrator 5, damping spring 3, motor transmission device 4 and control device, is characterized in that: A blind plate beam 13 is provided at the upper middle position of the screen box 1, and a track 9 is provided on both sides of the blind plate beam 13. The blind plate is arranged on the top of the track 9 through a roller 8, and the blind plate is formed by the upper blind plate 10 Composed of the lower telescopic blind plate, the upper blind plate 10 is a stepped blind plate with more than three layers, and can also be four to five layers. Each layer of the upper layer blind plate 10 is 200mm-250mm, and the size is 5000mm×5487mm, the installation inclination angle is 20°-22°. During operation, the non-magnetic mineral material does not have magnetic effect, so it is thrown out at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com