Body-in-white information management method and system

An information management and body-in-white technology, applied in the field of automobile manufacturing, can solve problems such as poor sharing, low efficiency, and increased costs, and achieve the effects of improving accuracy control, reducing personnel waste, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

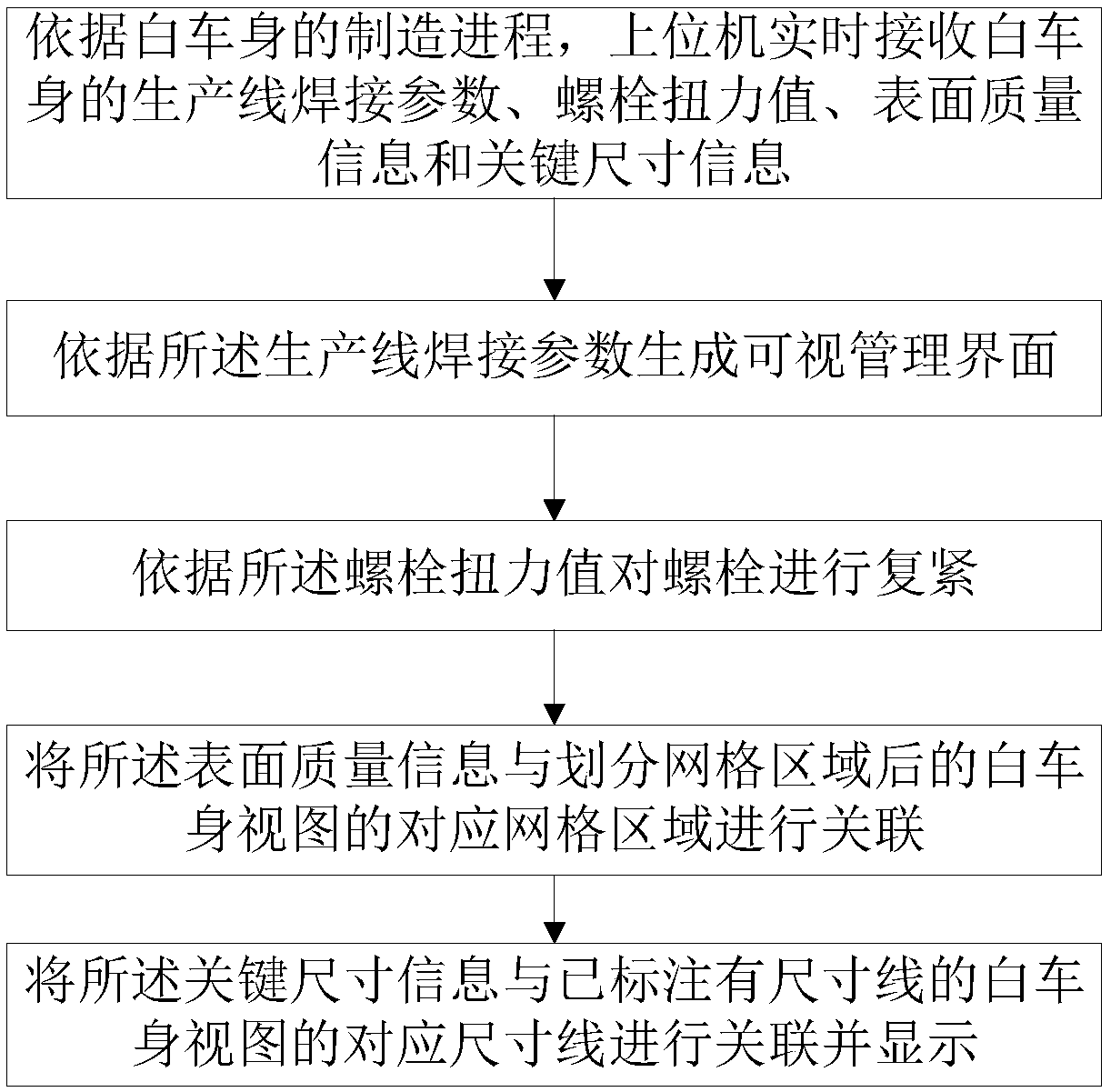

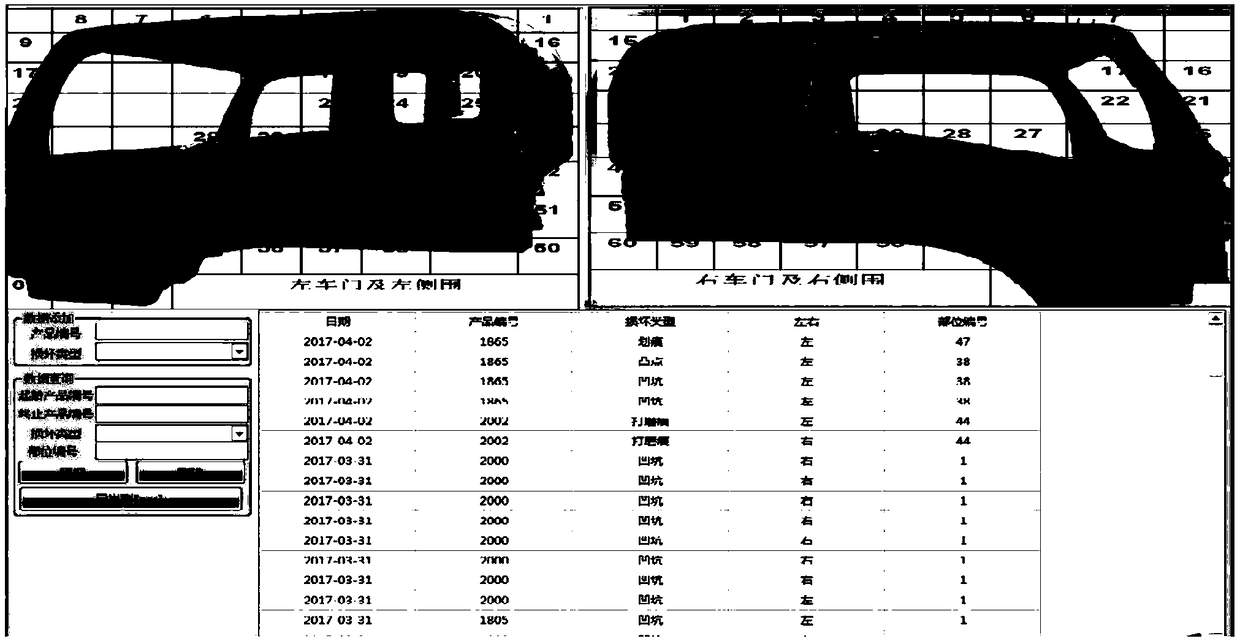

[0058] Please refer to Figure 1 to Figure 4 , the present embodiment provides a body-in-white information management method to realize informatization and intelligent management of body-in-white quality control. Specifically, the quality control of the welding process of the H3 wide-body half-in-white body is used as an example to illustrate, which may include the following steps:

[0059] S1: Designate the person in charge, approver, and executor on the computer side of the existing task assignment system (such as the smart enterprise ID task assignment system APP, which is applicable to mobile phones and PCs), specify content requirements, and specify completion time. Set the reward and punishment rules and importance; then issue the task, and the corresponding employee's hand-held terminal 13 (such as a mobile phone) will receive the corresponding work task, and can check, supervise, update, remind, etc. at any time.

[0060] Using the task assignment system for work arra...

Embodiment 2

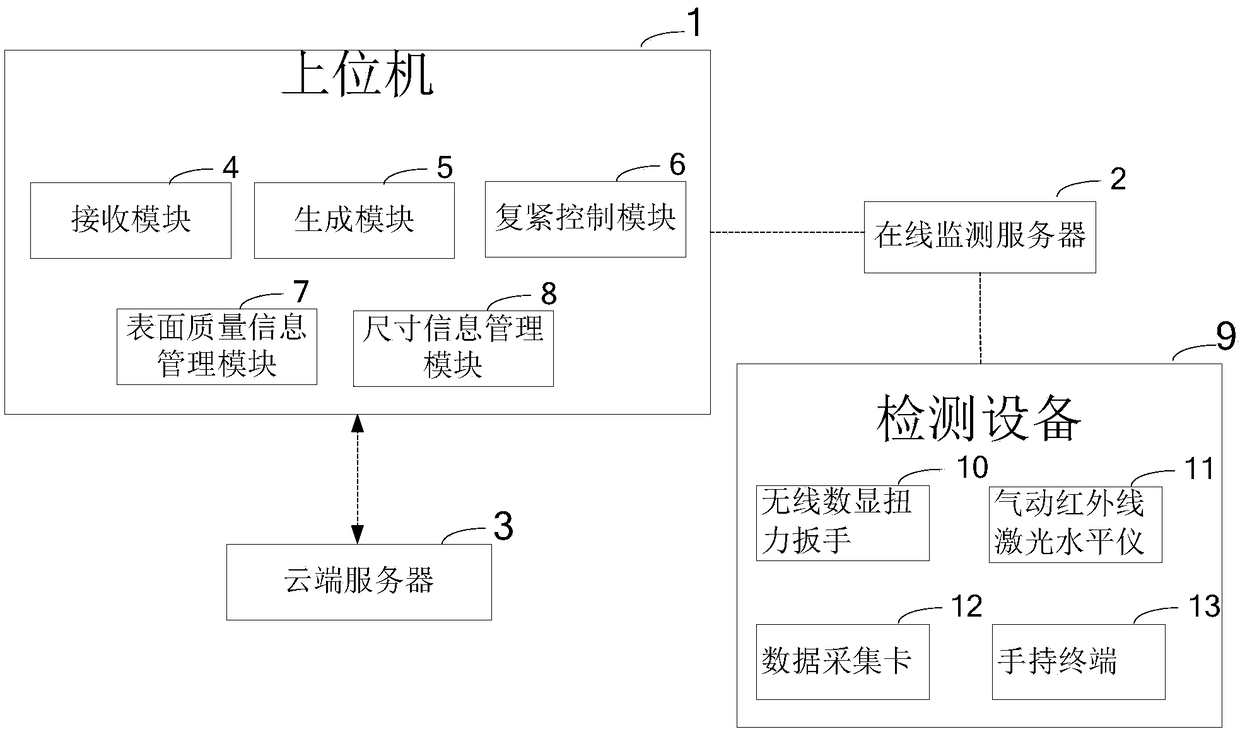

[0079] Please refer to figure 2 , on the basis of Embodiment 1, this embodiment provides a body-in-white information management system corresponding thereto, including a cloud server 3 wirelessly connected to the upper computer 1 and an online monitoring server 2 located offline; the online monitoring server 2 and the The detection equipment 9 of the offline process flow is connected to obtain various detection data; the detection equipment 9 includes a wireless digital display torque wrench 10, a pneumatic infrared laser level 11, a data acquisition card 12, and a handheld terminal 13; The data is sent to the host computer 1; after analyzing and processing the detection data, the host computer uploads it to the cloud server 3 for calling.

[0080] Specifically, the host computer includes:

[0081] The receiving module 4 is used to receive the production line welding parameters, bolt torque values, surface quality information and critical dimension information of the body in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com