Full-automatic deburring machine for removing burrs and copper powder crumbs of motor rotor commutator and operating method of deburring machine

A technology for motor rotors and deburring machines, applied to chemical instruments and methods, cleaning methods using liquids, cleaning methods and appliances, etc., can solve problems such as unsatisfactory, low efficiency of manual assembly, and limited product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

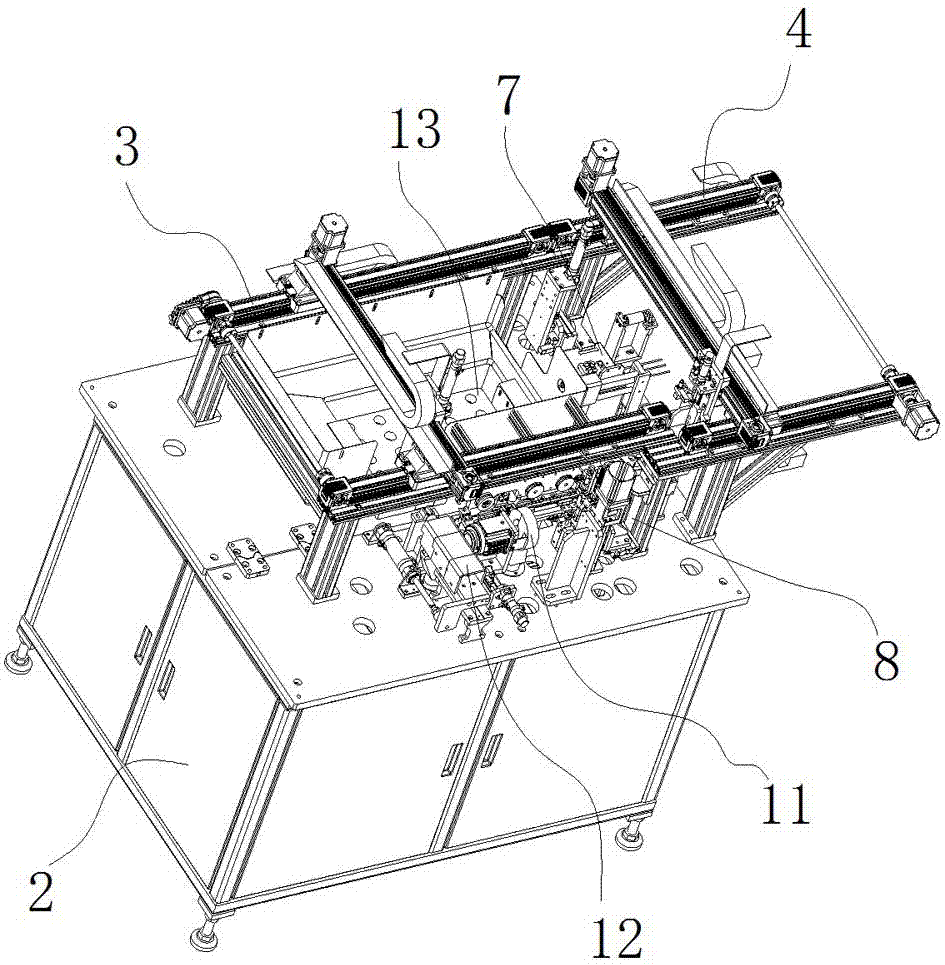

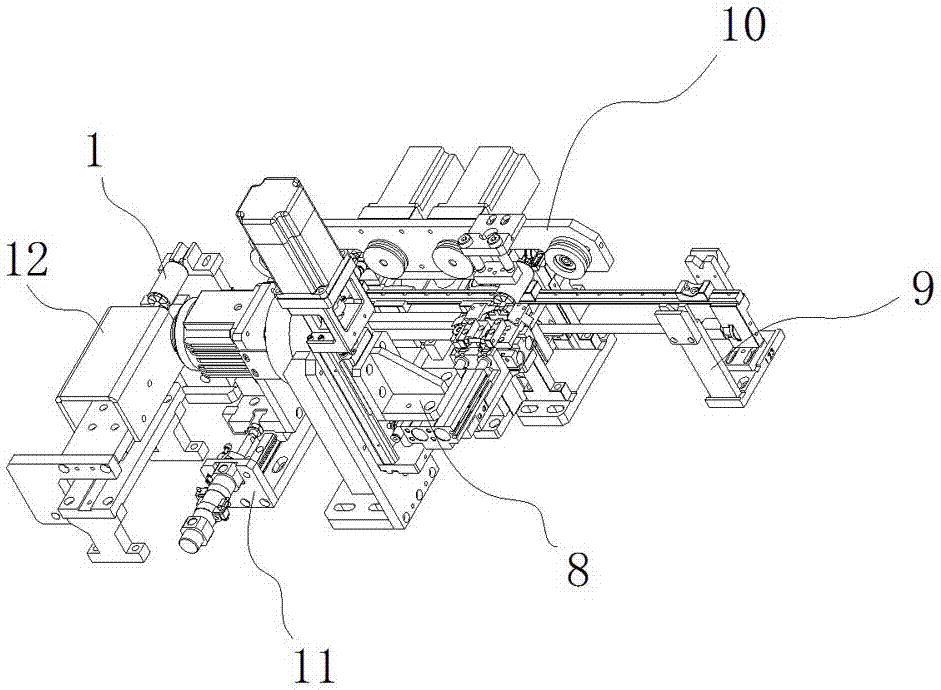

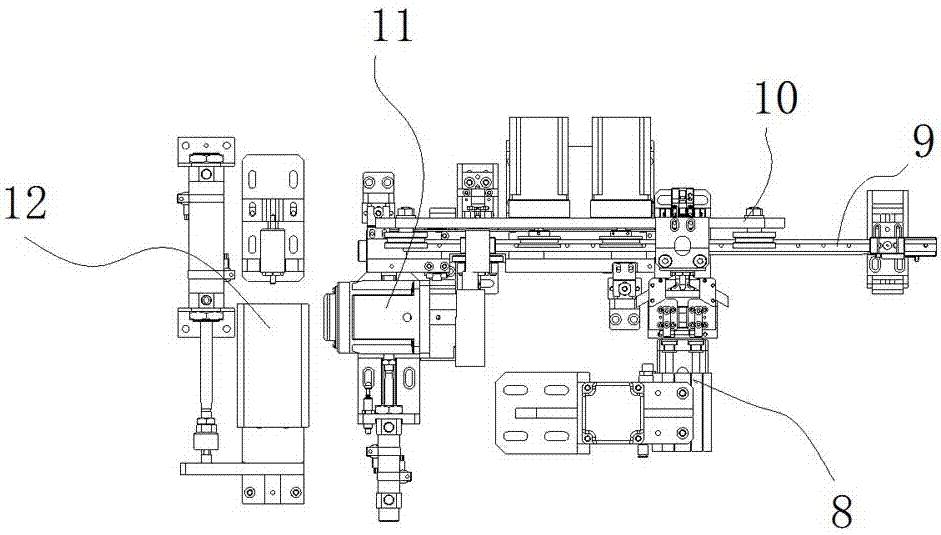

[0071] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a deburring machine for fully automatic removal of motor rotor commutator burrs and copper powder shavings includes a workpiece 1 and a frame (2), and the upper part of the frame 2 is provided with a left XYZ material shifting mechanism 3. Right XYZ material transfer mechanism (4), manipulator material transfer mechanism 5, manipulator clamping mechanism 5, air-drying degreasing mechanism 7, scraper deburring mechanism (8), transfer mechanism 9, rotating mechanism 10, brush wheel deburring Mechanism (11), high-pressure dedusting mechanism (12) and ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com