Wire saw bead string and manufacturing method thereof

A wire saw beading and manufacturing method technology, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of beaded lining and steel rope wear, increase the use cost of the wire saw, and break the wire saw, and achieve improvement. The effect of effective service life, improving material utilization and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

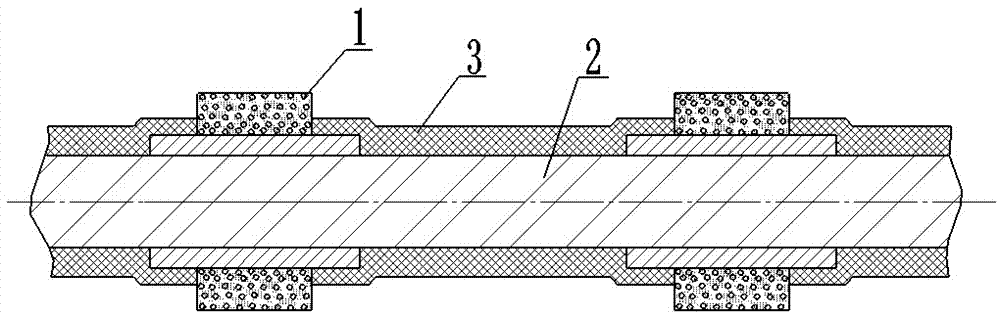

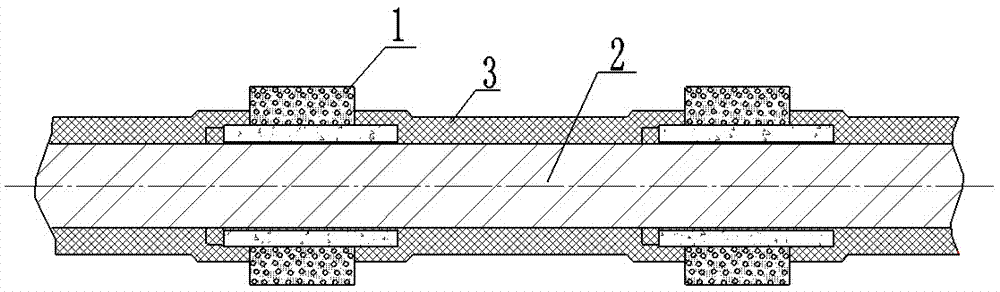

[0039] Embodiment 1, a method for manufacturing wire saw beads, including a carcass working layer and a liner, the specific implementation steps are as follows:

[0040] ① Electrolytic iron powder (particle size 150-200 mesh, weight 14.4kg), copper alloy powder CuSn15 (particle size 100-150 mesh, weight 4.0kg), diamond (particle size 70-80 mesh, weight 1.6kg), granulator 0.6kg Put into the mixing bucket and mix well.

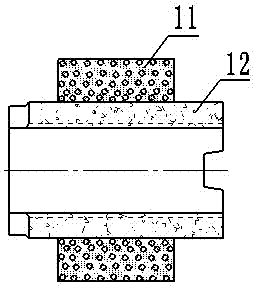

[0041]② Limited by the volume of the mixing drum of the granulator, the mixed powder is put into the granulator in 4 batches of 5.15 kg each, and then 0.15 kg of isopropanol is added to each batch to be granulated, sieved and dried. Use a cold-pressing die to press the liner cold-pressed green body 12 on a cold press. A single cold-pressed green body 12 weighs 1.95g, and its size is 8.0mm in outer diameter, 5.0mm in inner diameter and 11.0mm in height, and a corresponding concave Groove 121 and boss 122.

[0042] ③ The cold-pressed ring body 12 of the liner af...

Embodiment 2

[0044] Embodiment 2, a method for manufacturing wire saw beads, including a carcass working layer and a liner, the specific implementation steps are as follows:

[0045] ① Electrolytic iron powder (particle size 150-200 mesh, weight 14.4kg), copper alloy powder CuZn25 (particle size 100-150 mesh, weight 4.0kg), diamond (particle size 70-80 mesh, weight 1.6kg), granulator 0.6kg Put into the mixing bucket and mix well.

[0046] ② Limited by the volume of the mixing drum of the granulator, the mixed powder is put into the granulator in 4 batches of 5.15 kg each, and then 0.15 kg of isopropanol is added to each batch to be granulated, sieved and dried. Use a cold-pressing die to press the liner cold-pressed green body 12 on a cold press. A single cold-pressed green body 12 weighs 1.83g, and its size is 8.0mm in outer diameter, 5.0mm in inner diameter and 11.0mm in height, and a corresponding concave Groove 121 and boss 122.

[0047] ③ After the pressing, the cold-pressed ring bo...

Embodiment 3

[0049] Embodiment 3, a method for manufacturing wire saw beads, including a carcass working layer and a liner, the specific implementation steps are as follows:

[0050] ① Electrolytic iron powder (particle size 150-200 mesh, weight 17.0kg), copper alloy powder CuSn15 (particle size 100-150 mesh, weight 2.0kg), diamond (particle size 80-90 mesh, weight 1.0kg), granulator 0.6kg Put into the mixing bucket and mix well.

[0051] ② Limited by the volume of the mixing drum of the granulator, the mixed powder is put into the granulator in 4 batches of 5.15 kg each, and then 0.15 kg of isopropanol is added to each batch to be granulated, sieved and dried. Use a cold-pressing die to press the liner cold-pressed green body 12 on a cold press. A single cold-pressed green body 12 weighs 2.08g, and its size is 8.0mm in outer diameter, 5.0mm in inner diameter and 11.0mm in height, and a corresponding concave Groove 121 and boss 122.

[0052] ③ The cold-pressed ring body 12 of the liner a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com