Sludge recycling system

A technology of recycling and sludge, applied in the field of sludge recycling, can solve the problems of high organic content, spread of infectious diseases, perishable odor, etc., and achieve good fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

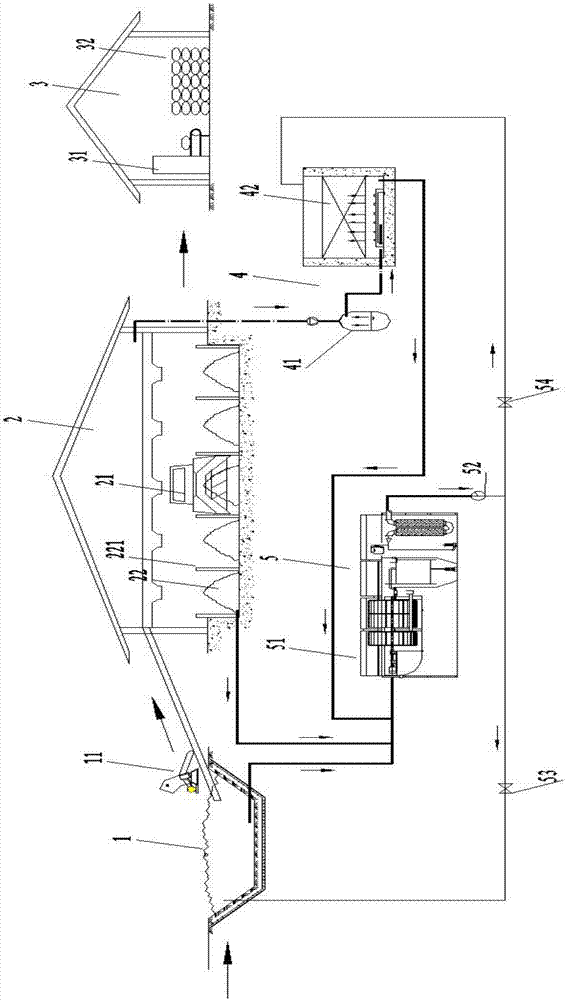

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] A sludge recycling system, referring to figure 1 , including a sludge thickener (1), a belt filter press (11), a fermentation room (2), and a finished product area (3) connected in sequence. The fermented clinker is sent into the clinker bin by the excavator, and stacked by the loader into stacks according to the order of leaving the bin. After about 7 days of aging, the finished product can be packaged and shipped out. Sewage collection canals are installed on the indoor ground of the turnover adjustment tank, fermentation tank and fermentation room, and the collected sewage enters the sewage treatment area (5), including buried JYZ integrated membrane treatment equipment (51) for treatment, and the sewage effluent is passed through Lift pump (52) to control valve 2 (53) biofilter or control valve 1 (54) sludge thickener. The composting treatment ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com