Heat treatment method capable of improving room-temperature impact toughness of austenitic heat-resistant steel after aging

A technology of austenitic heat-resistant steel and heat treatment method, which is applied in the field of heat treatment to improve the room temperature impact toughness of austenitic heat-resistant steel after aging, and can solve the problem of the reduction of the impact toughness at room temperature of the material, shortening the service life of unit components, and affecting the safe operation of the unit. and other problems, to achieve the effect of improving impact toughness, improving impact toughness drop, and improving room temperature impact toughness performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

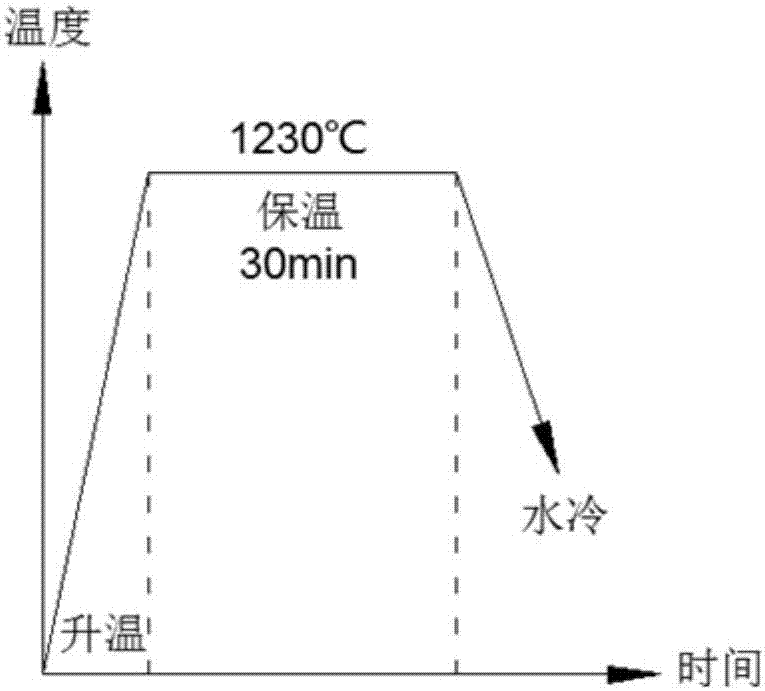

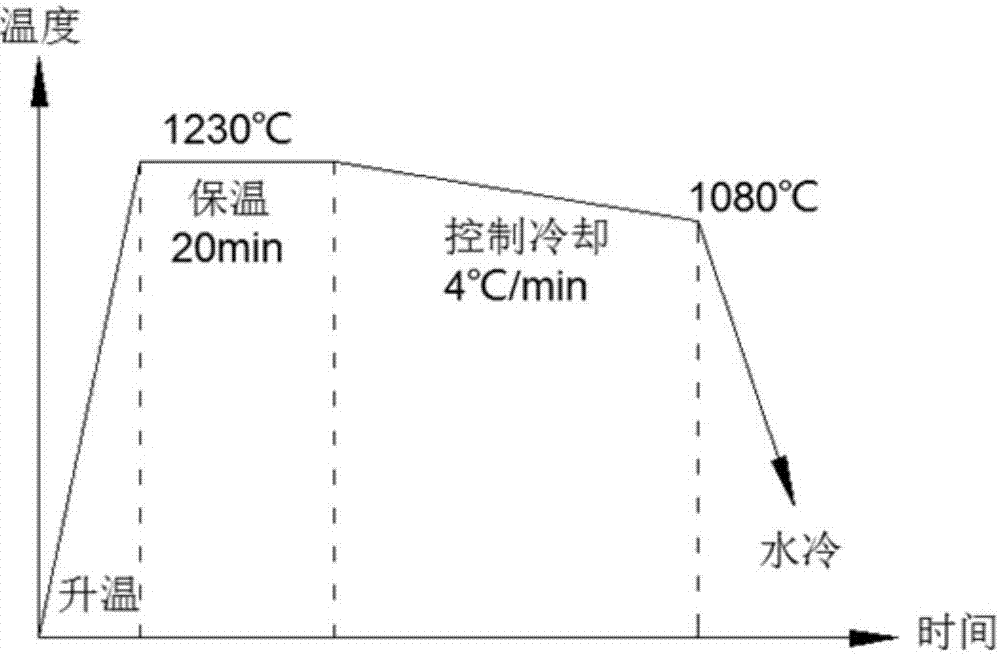

[0039] The present invention is a heat treatment method for improving the room temperature impact toughness of austenitic heat-resistant steel after aging, comprising the following steps,

[0040] Step 1, heating the austenitic heat-resistant steel to 1230°C;

[0041] Step 2, keeping the heated austenitic heat-resistant steel at 1230°C for 20 minutes;

[0042] Step 3, cooling the heat-preserved austenitic heat-resistant steel to 1080°C at a cooling rate of 4°C / min;

[0043] Step 4, cooling the austenitic heat-resistant steel down to 1080°C in water to room temperature.

[0044] Among them, the chemical composition of the austenitic heat-resistant steel in this example is shown in Table 2.

[0045] Table 2 The chemical composition of the austenitic heat-resistant steel in Example 1 (mass%, the balance is Fe).

[0046] Ni Cr Nb Si N C B Zr P co V Ce 19 24 0.6 0.3 0.18 0.1 0.002 0.002 0.02 4.6 0.1 0.005

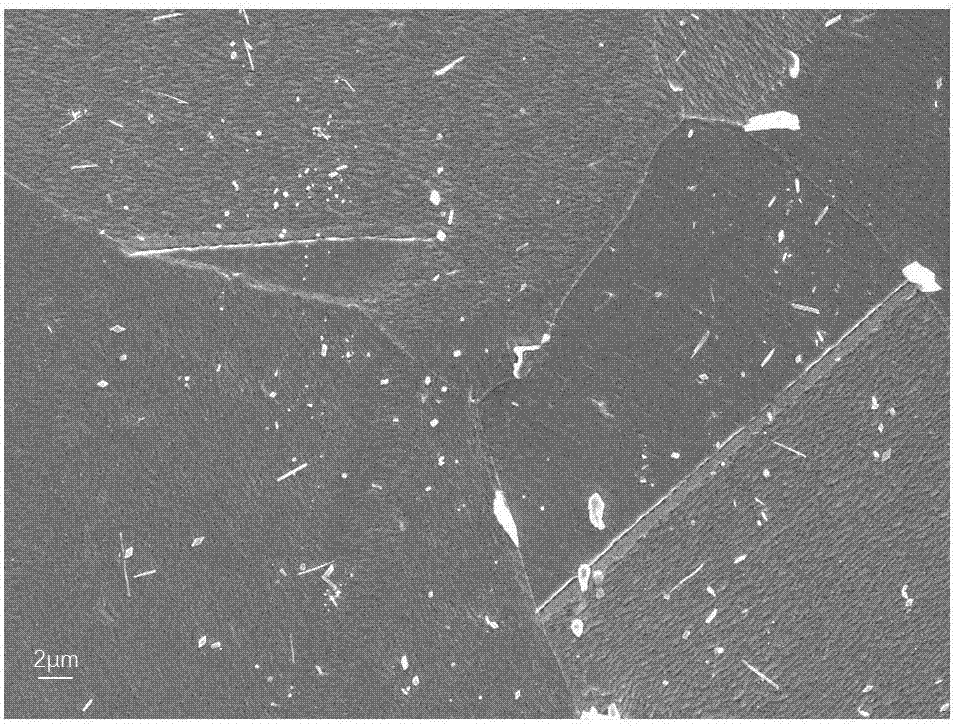

[0047] The sample in this e...

example 2

[0054] The present invention is a heat treatment method for improving the room temperature impact toughness of austenitic heat-resistant steel after aging, comprising the following steps,

[0055] Step 1, heating the austenitic heat-resistant steel to 1220°C;

[0056] Step 2, keeping the heated austenitic heat-resistant steel at 1220°C for 25 minutes;

[0057] Step 3, cooling the heat-preserved austenitic heat-resistant steel to 1100°C at a cooling rate of 5°C / min;

[0058] Step 4, cooling the austenitic heat-resistant steel down to 1100°C in water to room temperature.

[0059] Among them, the chemical composition of the austenitic heat-resistant steel in this example is shown in Table 2.

[0060] Table 2 The chemical composition of the austenitic heat-resistant steel in Example 1 (mass%, the balance is Fe).

[0061] Ni Cr mn Nb Si N C B Zr P co V Ce 17 25 2.0 0.6 0.75 0.15 0.04 0.002 0.002 0.03 4.6 0.1 0.005

example 3

[0063] The present invention is a heat treatment method for improving the room temperature impact toughness of austenitic heat-resistant steel after aging, comprising the following steps,

[0064] Step 1, heating the austenitic heat-resistant steel to 1240°C;

[0065] Step 2, keeping the heated austenitic heat-resistant steel at 1240°C for 15 minutes;

[0066] Step 3, cooling the heat-preserved austenitic heat-resistant steel to 1060°C at a cooling rate of 3°C / min;

[0067] Step 4, cooling the austenitic heat-resistant steel down to 1060°C in water to room temperature.

[0068] Among them, the chemical composition of the austenitic heat-resistant steel in this example is shown in Table 2.

[0069] Table 2 The chemical composition of the austenitic heat-resistant steel in Example 1 (mass%, the balance is Fe).

[0070] Ni Cr mn Nb Si N C B Zr P co V Ce 23 26 1.0 0.2 0.1 0.35 0.07 0.002 0.002 0.01 4.6 0.1 0.005

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com