Magnetic control sputtering continuous line for preparing fuel cell metal bipolar plate non-crystalline carbon film

A metal bipolar plate and magnetron sputtering technology, applied in sputtering coating, metal material coating process, ion implantation plating, etc., can solve the problem of inability to maintain different process conditions in different chambers and reduce coating preparation efficiency , different working environments and other issues, to achieve the effect of preventing target pollution, accelerating industrialization development, and good film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

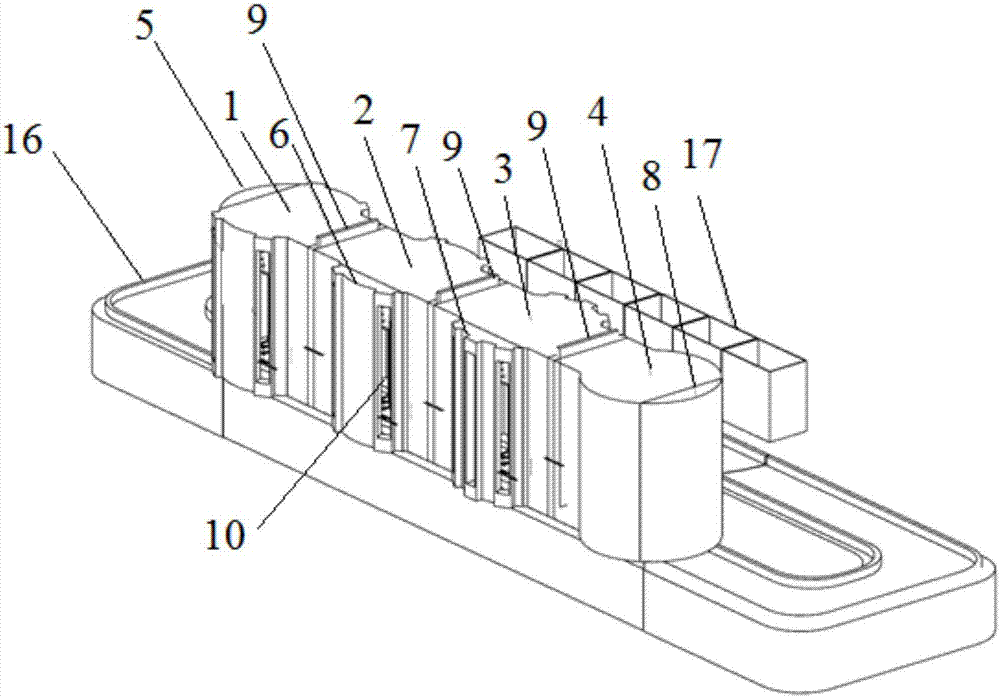

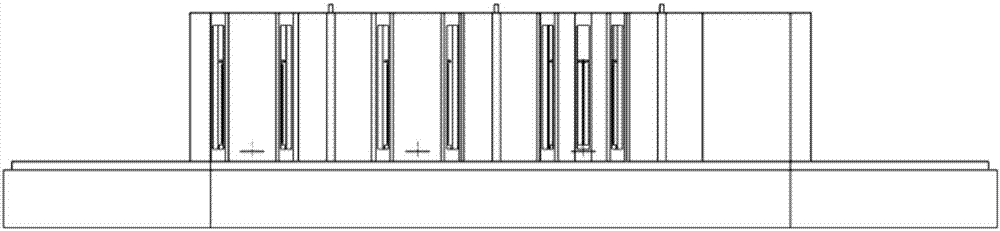

[0050] A sputtering continuous line for efficient coating of amorphous carbon film on metal bipolar plates of fuel cells, including multi-chamber system, workpiece rack, transmission system, isolation valve, vacuum control system, electric control system, sputtering target and Conventional structures such as vacuum sputtering equipment, which include:

[0051] multi-chamber systems such as Figure 1-3 As shown, it is composed of a cleaning heating chamber 1, a first coating chamber 2, a second coating chamber 3 and a subsequent processing chamber 4. The cleaning heating chamber 1 is provided with a continuous line inlet door 5, and the first coating chamber The first airtight door 6 and the second airtight door 7 are arranged on the chamber 2 and the second coating chamber 3 respectively, and the continuous line outlet door 8 is arranged on the subsequent processing chamber 4 . Isolation valve 9 is arranged in the transition part of two adjacent chambers, and sputtering targe...

Embodiment 2

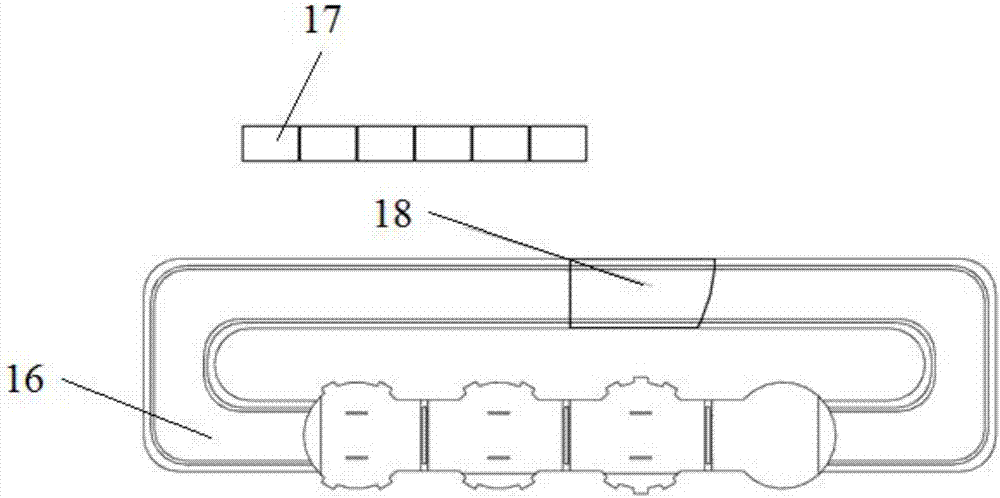

[0056] Compared with Embodiment 1, except that the workpiece frame and the transmission system are different, the rest are the same. The workpiece frame and transmission system of the present embodiment are designed as follows:

[0057] like Figure 7 , 8 As shown, the transmission system consists of a chamber outer guide rail 21, a rotatable transition guide rail 22, a chamber inner guide rail 23, a large gear 24 at the bottom of the chamber, and rollers 25 installed on the bottom and top of the hanger (roller 25 can make the hanger b Smooth movement along the guide rail) and the corresponding PLC control system. The workpiece rack consists of hangers b20 placed in series on the conveyor system at a fixed distance. When working, the adjacent hangers b20 are connected in series at a fixed distance, the outer guide rail 21 of the chamber and the inner guide rail 23 of the chamber are fixed, and the transition guide rail 22 can rotate around the fixed and chamber point. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com