A kind of pearlescent holographic anti-counterfeiting paper and its preparation process

A holographic anti-counterfeiting and preparation technology, which is applied in the field of pearlescent holographic anti-counterfeiting paper and its preparation, to achieve the effects of cost saving, good pearlescent effect and strong anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

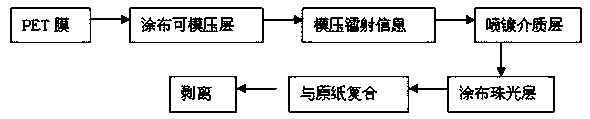

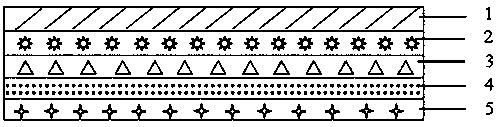

Method used

Image

Examples

Embodiment 1

[0024] 1. Coat the moldable transfer coating on the coating machine at a speed of 100m / min, and use a 250-mesh screen roller to coat the surface of the 12µm PET film. The drying tunnel is used to dry and form a film.

[0025] 2. Use a molding machine at a speed of 40m / min, a molding pressure of 20kg, and a molding temperature of 130°C to imprint and transfer the laser information of the horizontal textured light column on the nickel plate to the moldable coating; the thickness of the molded laser layer is 1.0µm , to obtain the PET film containing the laser pattern of the horizontal net pattern.

[0026] 3. Send the PET film with laser information into the vacuum spraying system, and the vacuum degree is 5×10 -2 A layer of ZnS dielectric layer with a thickness of 0.20 µm and a purity of ≥99.0% is sprayed under Pa conditions.

[0027] 4. Weigh 25 parts of golden pearl powder with a particle size of 15µm, disperse it into 75 parts of transparent water-based polyurethane paint ...

Embodiment 2

[0034] 1. Coat the moldable transfer coating on the coating machine at a speed of 120m / min, and use a 200-mesh wire roller to coat the surface of the 15µm PET film. The drying tunnel is used to dry and form a film.

[0035] 2. Using a molding machine at a speed of 50m / min, a molding pressure of 22kg, and a molding temperature of 150°C, transfer the plain laser information on the nickel plate to the moldable coating; the thickness of the molded laser layer is 1.5µm, and the obtained Plain laser patterned PET film.

[0036] 3. Send the PET film with laser information into the vacuum spraying system, and the vacuum degree is 5×10 -2 A layer of ZnS dielectric layer with a thickness of 0.20 µm and a purity of ≥99.0% is sprayed under Pa conditions.

[0037]4. Weigh 15 parts of white pearlescent powder with a particle size of 40µm, and disperse it into 85 parts of blue water-based polyurethane paint with a mixer at room temperature, and stir until the pearlescent powder is complet...

Embodiment 3

[0044] 1. Coat the moldable transfer coating on the coating machine at a speed of 150m / min, and use a 300-mesh screen roller to coat the surface of the 18µm PET film. The drying tunnel is used to dry and form a film.

[0045] 2. Using a molding machine at a speed of 60m / min, a molding pressure of 23kg, and a molding temperature of 175°C, the laser information imprinting of the mirror beam on the nickel plate is transferred to the moldable coating; the thickness of the molded laser layer is 1.2µm, and the obtained PET film with mirror laser pattern.

[0046] 3. Send the PET film with laser information into the vacuum spraying system, and the vacuum degree is 5×10 -2 A layer of ZnS dielectric layer with a thickness of 0.20 µm and a purity of ≥99.0% is sprayed under Pa conditions.

[0047] 4. Weigh 20 parts of red pearlescent powder with a particle size of 80µm, and disperse it into 80 parts of transparent water-based polyurethane paint with a mixer at room temperature, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com