Precast assembly type shear wall

A prefabricated assembly and shear wall technology, which is applied in the processing of walls, buildings, and building materials, can solve the problems of complex and non-removable assembly process of prefabricated shear walls, and achieve tight connection, improve efficiency, and simplify the assembly process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

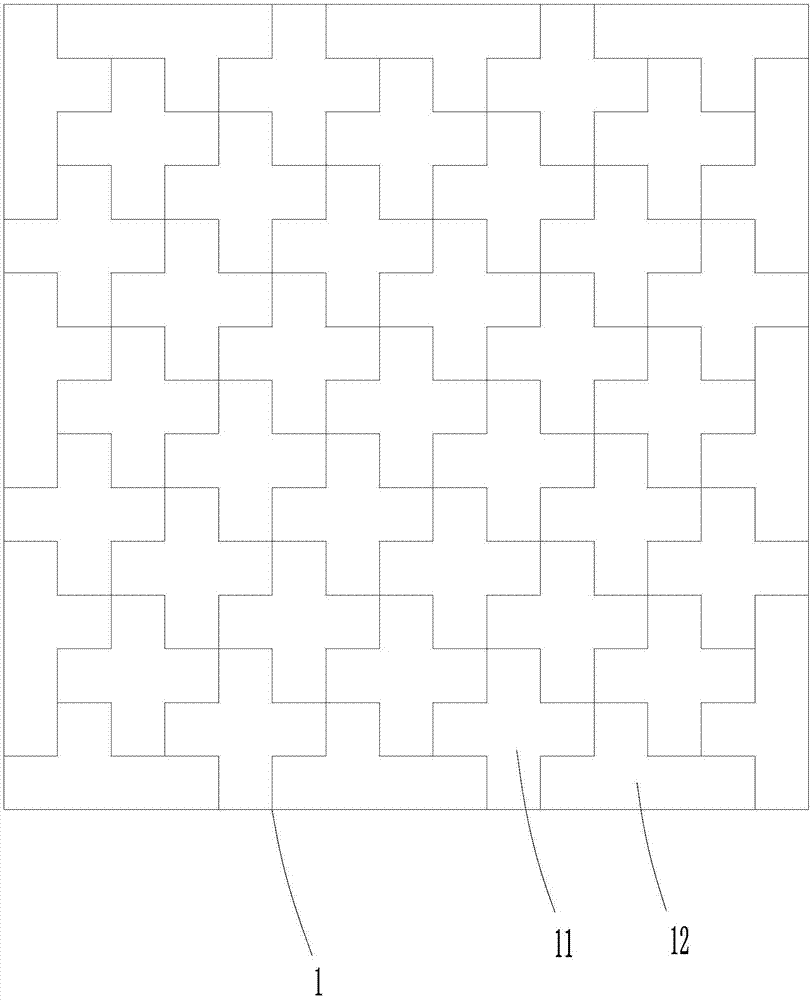

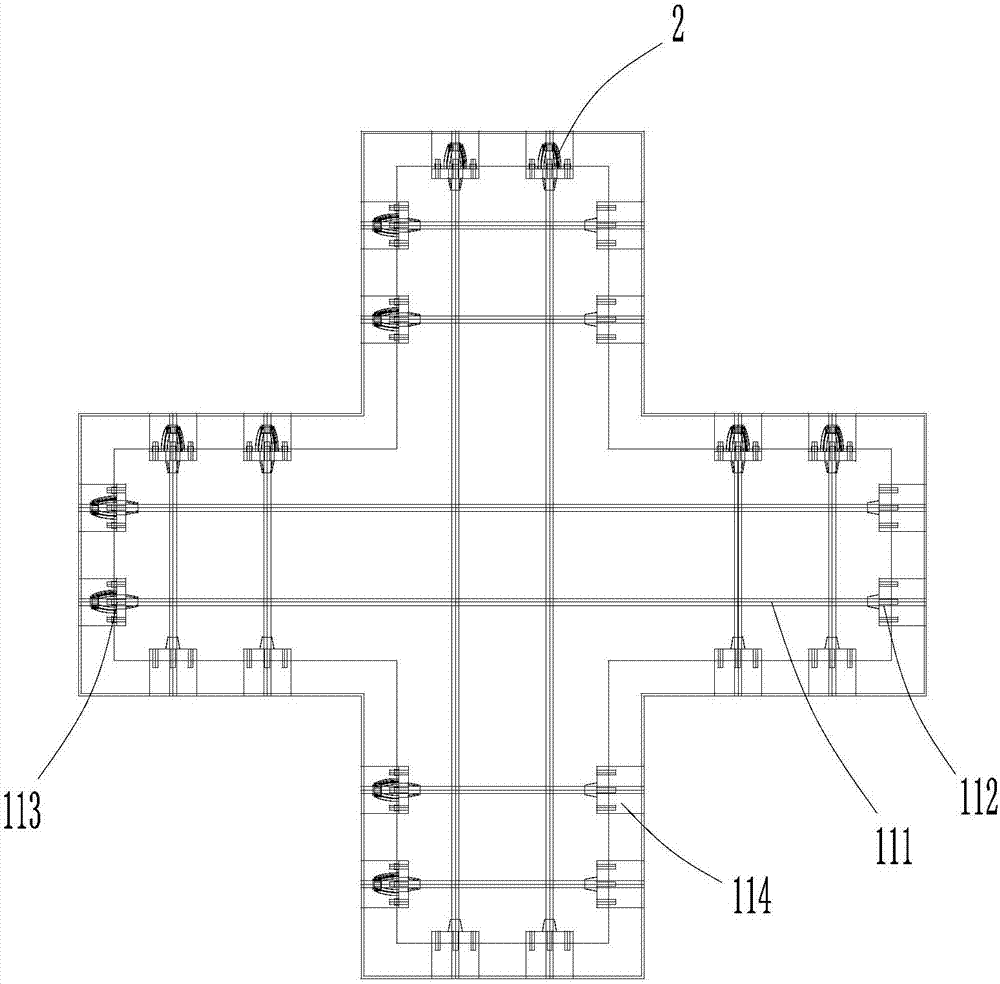

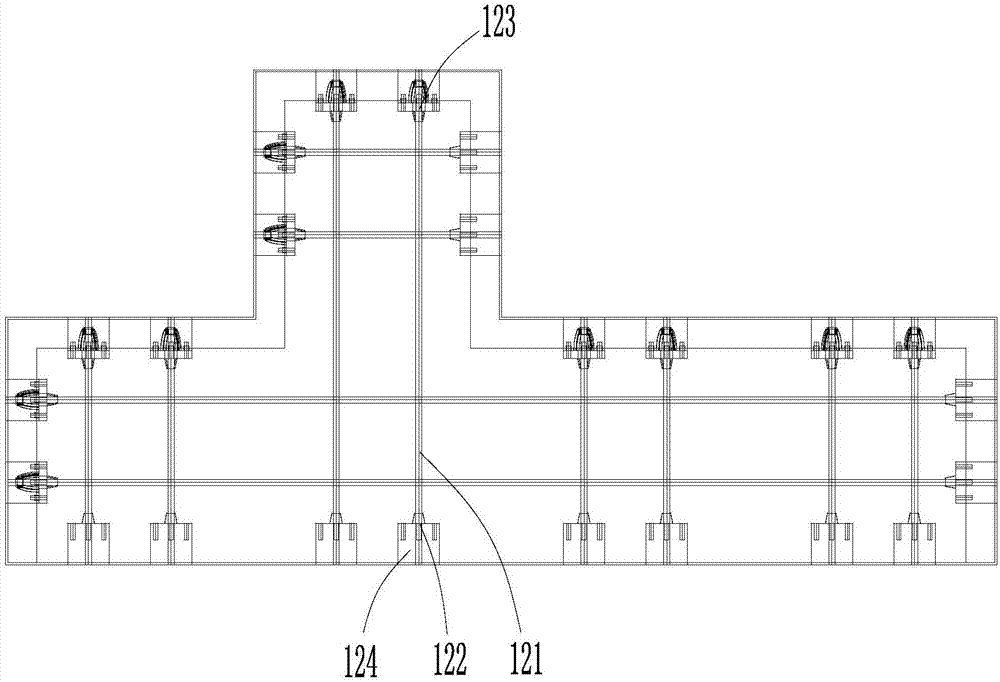

[0041] This embodiment provides a prefabricated assembly type shear wall, such as Figure 1-2 As shown, it includes component 1 and connector 2.

[0042] Wherein, component 1 comprises cross-shaped component 11, similar T-shaped component 12, and cross-shaped component 11 is provided with the through hole 111 that is used to pass through prestressing tendon, and the inlet 112 of through hole and outlet 113 are all provided with groove 114; The T-shaped member 12 is provided with a through hole 121 for passing through the prestressing tendons, and the inlet 122 and the outlet 123 of the through hole are all provided with grooves 124;

[0043] Connector 2, which is fixed in the groove 104, includes a front anchoring end 201 and a rear anchoring end 202, a cavity 203 is provided between the front anchoring end and the rear anchoring end, and the front anchoring end and the rear anchoring end are respectively connected to different pre-anchor ends. stress tendon;

[0044] An anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com