Drilling test device and method used for shield model test

A technology of model test and test device, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problem that it is difficult to simultaneously consider the influence of surrounding soil layer disturbance shield tail grouting on formation deformation, shield tunnel excavation and grouting There are few problems such as synchronous simulation research, to achieve the effect of stable air pressure, good applicability, and easy collection and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

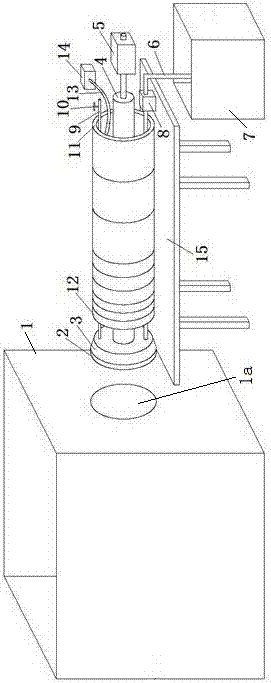

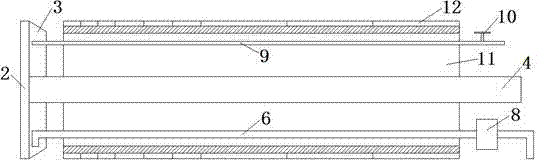

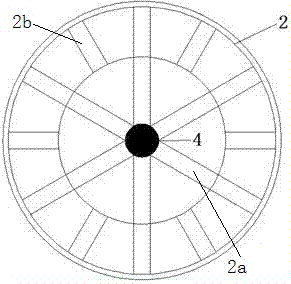

[0032] refer to Figure 1 to Figure 4

[0033] A drilling-type test device for shield model testing, including a workbench 15, on which a tunnel round pipe 11 is arranged, and a cutter head 2 driven by a driving mechanism is arranged on the front side of the tunnel round pipe , the rear side of the cutter head is provided with an airtight chamber 3 for storing excavated muck, and the inner area of the airtight chamber must be sealed during the excavation process. The lower part of the airtight chamber is provided with a slag-absorbing mechanism, and the upper part of the airtight chamber is provided with a ventilation mechanism which completes the opening and closing synchronously with the slag-absorbing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com