Control device for vehicle tail gas purification

A technology for exhaust gas purification and control devices, which is applied in electrical control, engine control, fuel injection control, etc., and can solve problems such as reducing exhaust emissions, three-way catalytic converters are prone to aging, and cannot truly reflect the working conditions of the engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

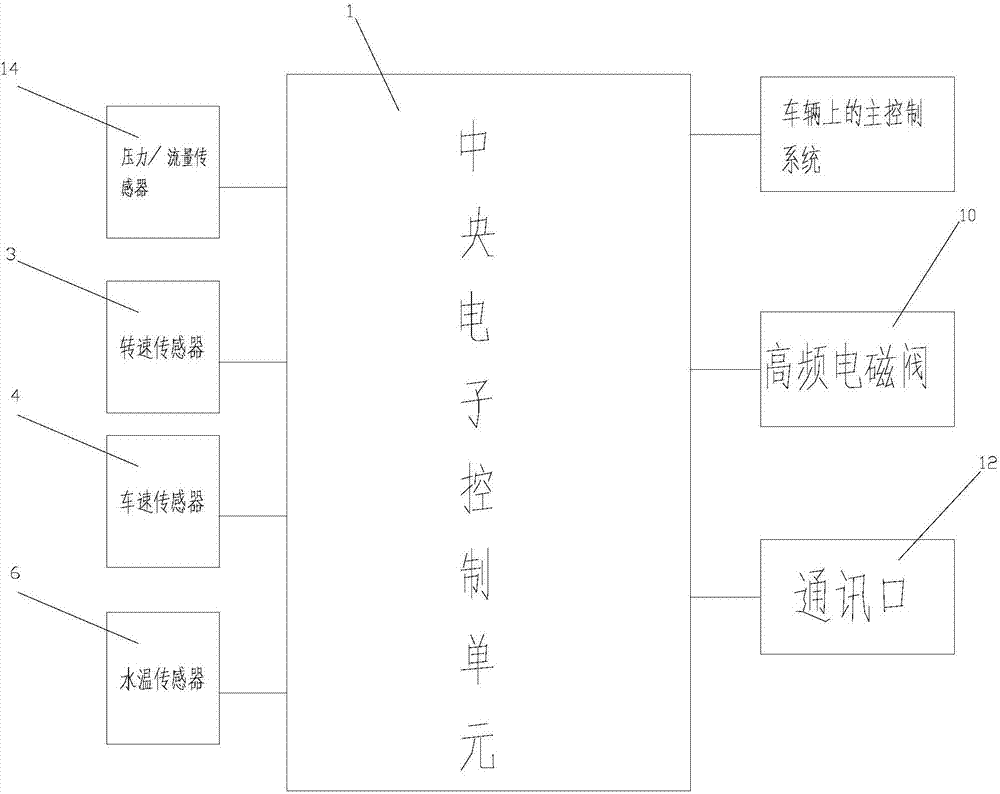

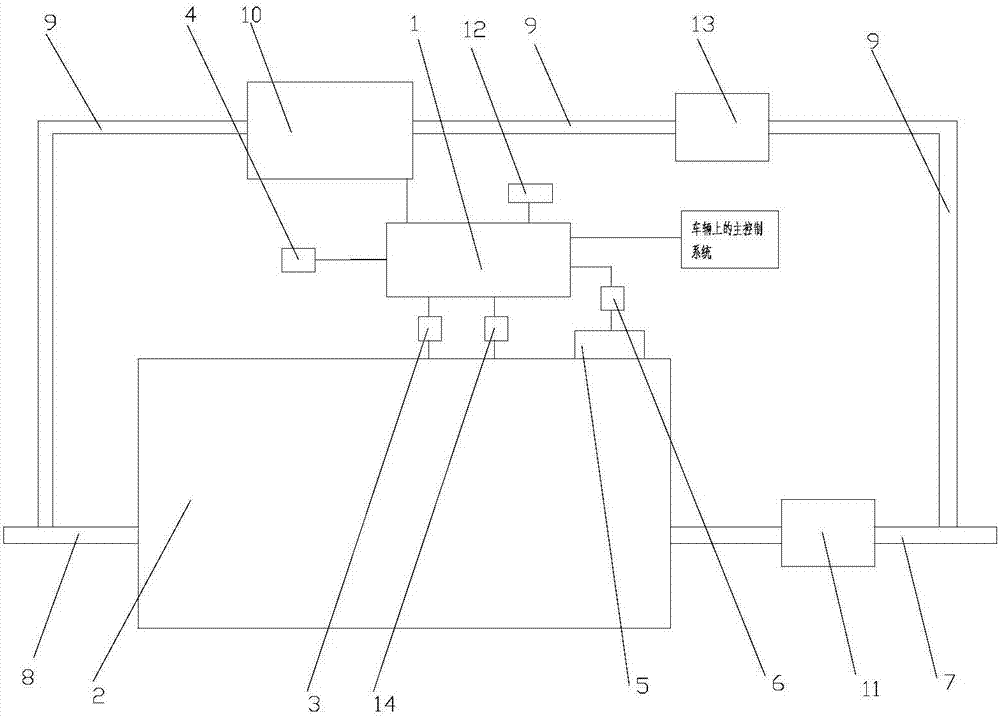

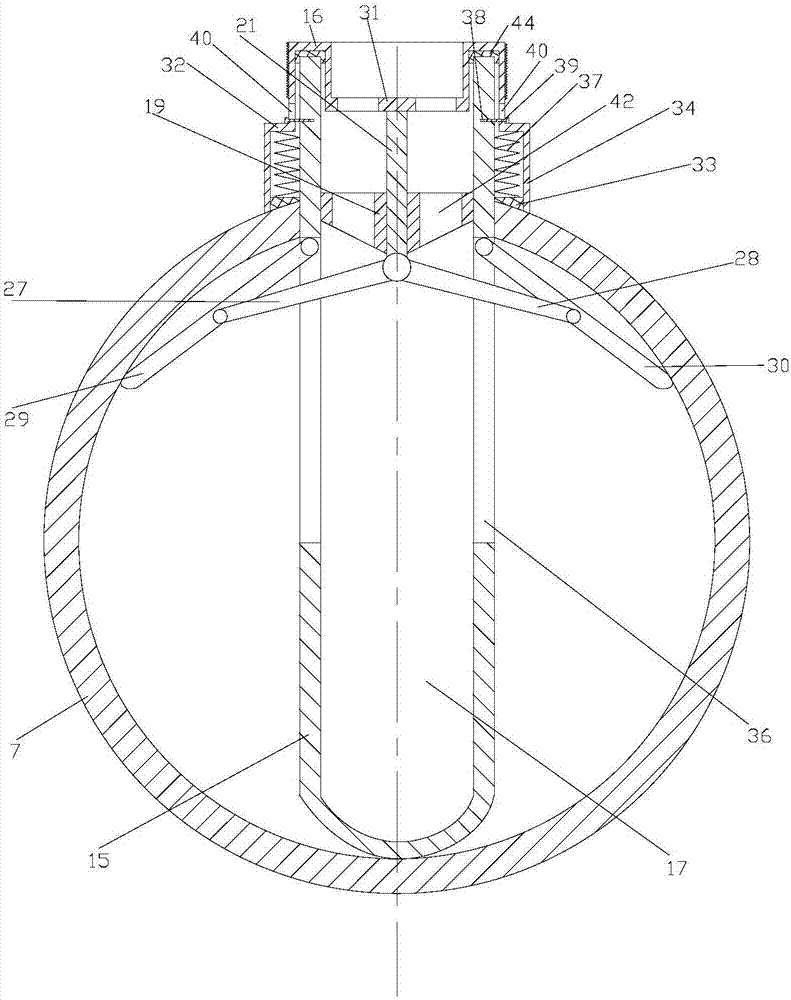

[0027]As shown in the figure, it includes a central electronic control unit (ECU) 1, a rotational speed sensor 3 for measuring the rotational speed of the crankshaft on the engine 2, a vehicle speed sensor 4 for measuring the rotational speed of the automobile tires, and a temperature sensor 5 for measuring the upper water tank 5 of the engine 2. The water temperature sensor 6, the pressure / flow sensor 14 used to measure the pressure / flow on the engine 2 and the engine exhaust gas recirculation EGR electronic control system; the speed sensor 3 is connected to the input end of (ECU) 1 through a signal connection, and the vehicle speed sensor 4 is connected to the (ECU) )1 input terminal is connected via signal, water temperature sensor 6 is connected with (ECU)1 input terminal via signal, pressure / flow sensor 14 is connected with (ECU)1 input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com