Laser lighting lamp

A lighting lamp and laser technology, applied in the field of lighting, can solve the problems of burning out other parts of the laser light source, high heat generation of the laser light source, high heat dissipation requirements, etc., to achieve the effect of increasing the irradiation distance, the long irradiation distance, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

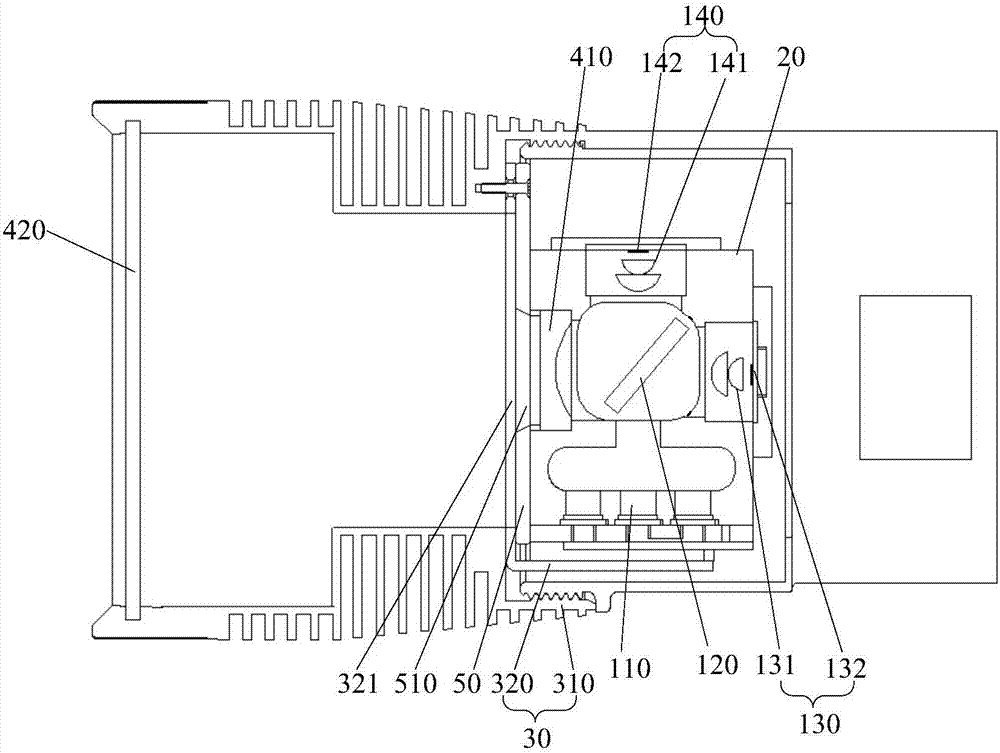

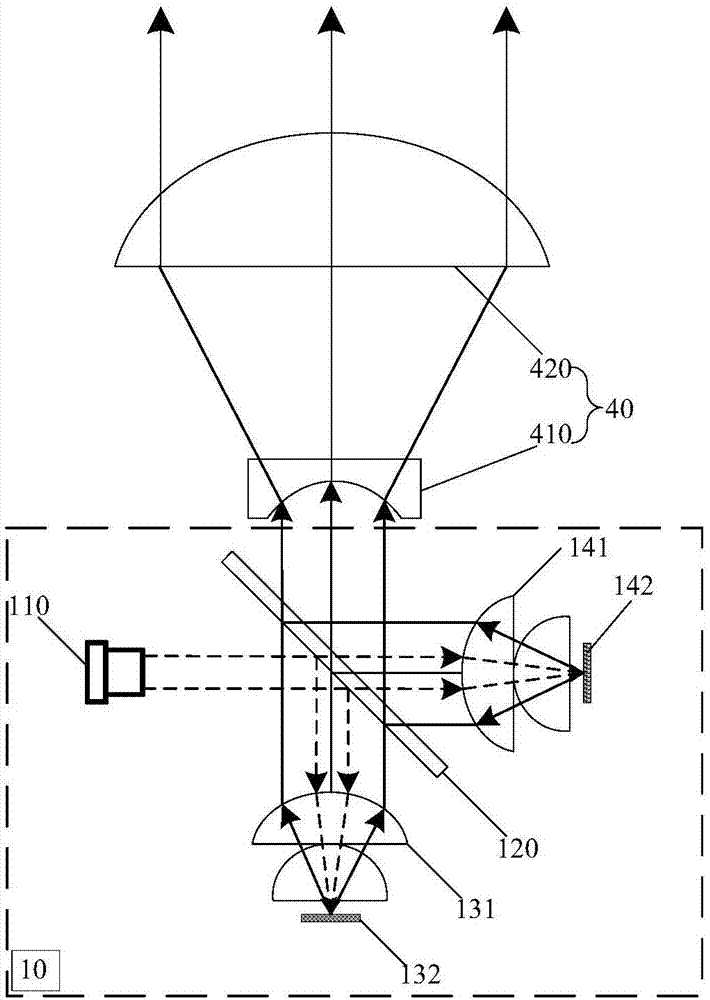

[0020] Such as figure 1 As shown, the present invention provides a laser lighting lamp, including a light emitting unit 10, an installation unit 20 for fixing the light emitting unit 10, and a heat dissipation unit 30 respectively connected to the light emitting unit 10 and the installation unit 20, the The light emitting unit 10 includes a laser source 110, the heat dissipation unit 30 includes a heat dissipation housing 310 sleeved on the outer periphery of the installation unit 20, and a heat conducting member 320 located between the laser source 110 and the heat dissipation housing 310, the light emitting The outgoing beam of the unit 10 exits along the axial direction of the heat dissipation housing 310 , the laser source 110 is located on the side of the mounting unit 20 perpendicular to the outgoing light beam, and the heat conducting member 320 has an L-shaped structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com