Retractable magnetizing current lead device and method of same

A current lead and retractable technology, applied in the direction of superconducting magnets/coils, circuits, magnetic objects, etc., can solve the problems that the temperature of the cold screen cannot be lowered very low, the superconducting magnet cannot work normally, and the heat leakage is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

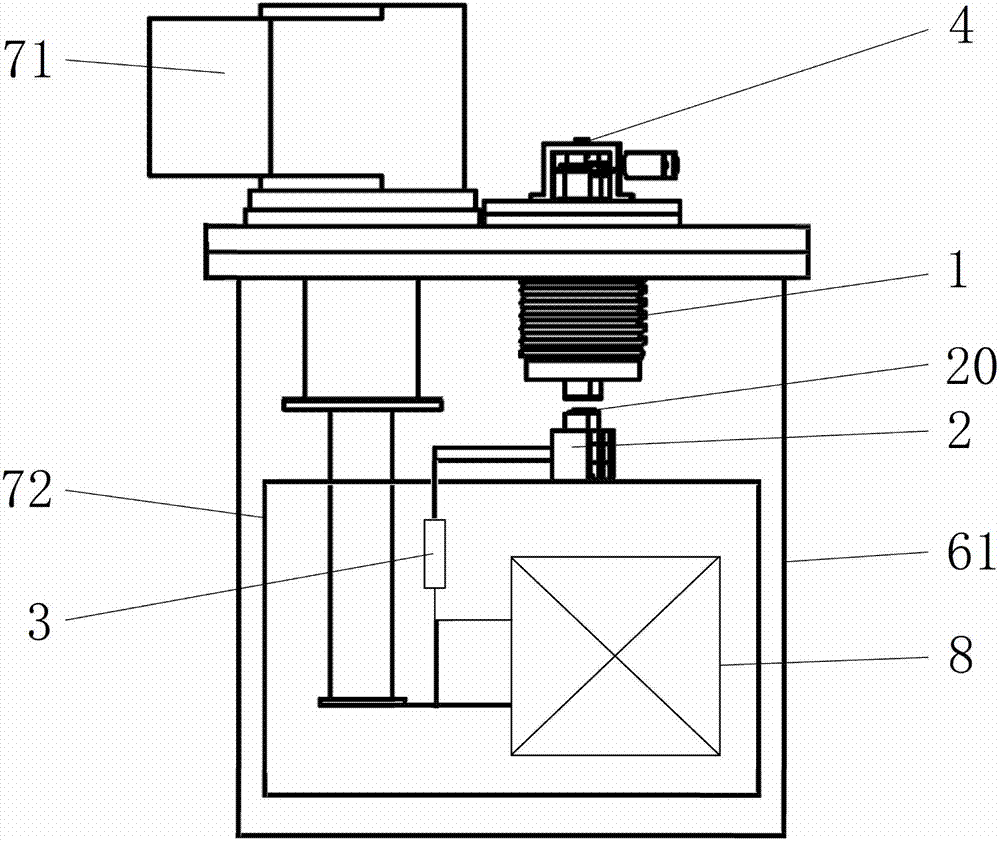

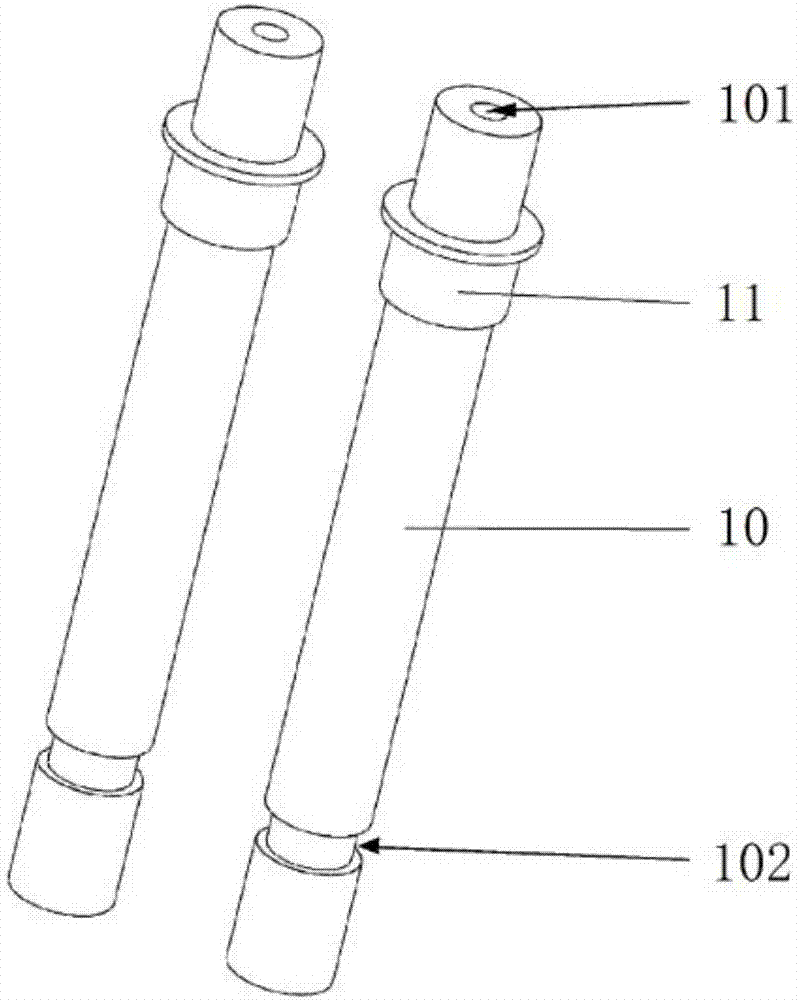

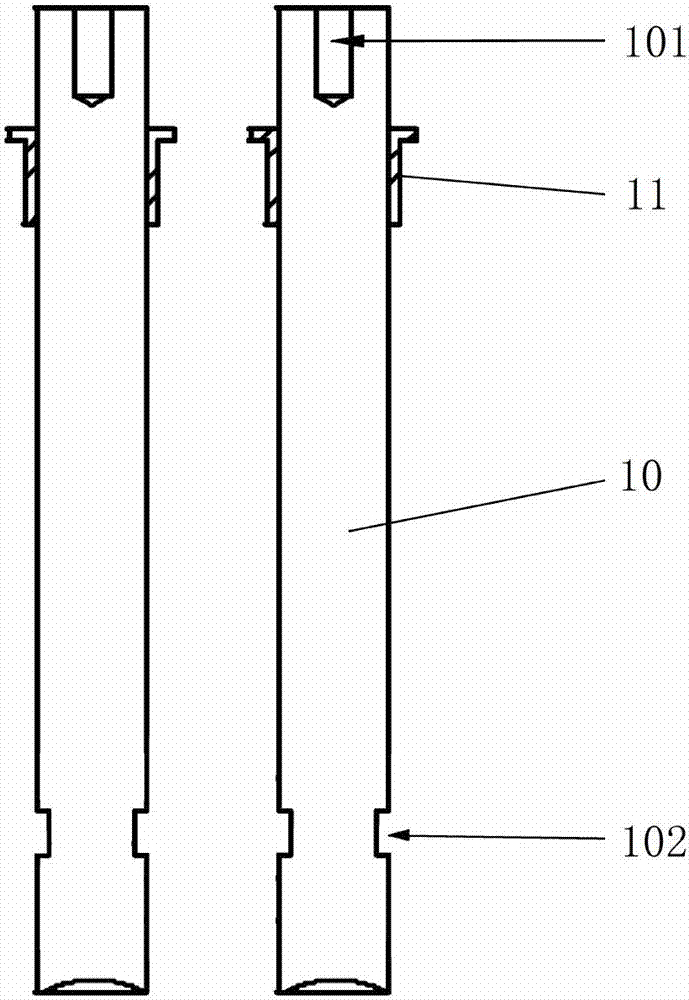

[0032] Such as figure 1 As shown, a retractable magnetizing current lead device of the present invention includes a retractable normal lead segment 1 arranged in a liquid nitrogen chamber, a high temperature superconducting transition lead segment 2 thermally connected to a cold head 71, and a low temperature The superconducting coil lead-out line section 3 has three parts; the retractable normal lead line section 1 is connected to the high-temperature part; the high-temperature superconducting transition lead-in section 2 is connected to the low-temperature part; the low-temperature superconducting coil lead-out line section 3 is connected to the superconducting Conductor coil 8; the lower end of the retractable normal lead segment 1 and the upper end of the high-temperature superconducting transition lead segment 2 are plugged into the retra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com