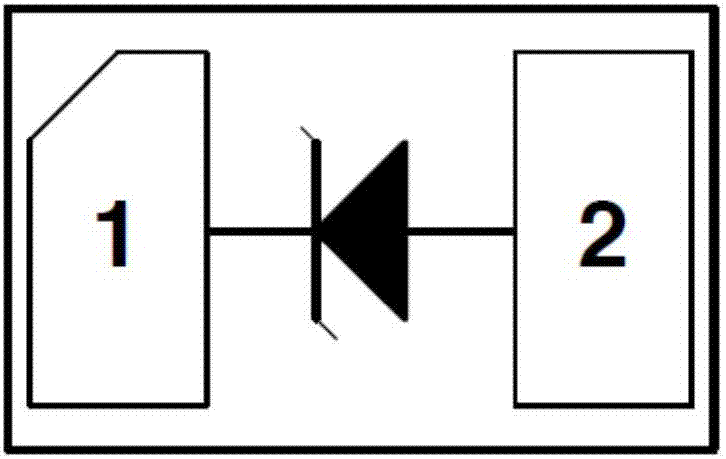

Structure and process for realizing WLCSP six-side plastic sealing of TVS chip

A chip and process technology, applied in the field of semiconductor packaging, can solve problems that affect the reliability of electronic products, difficult side insulation protection, chip side pollution, etc., achieve low cost, improve product performance, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

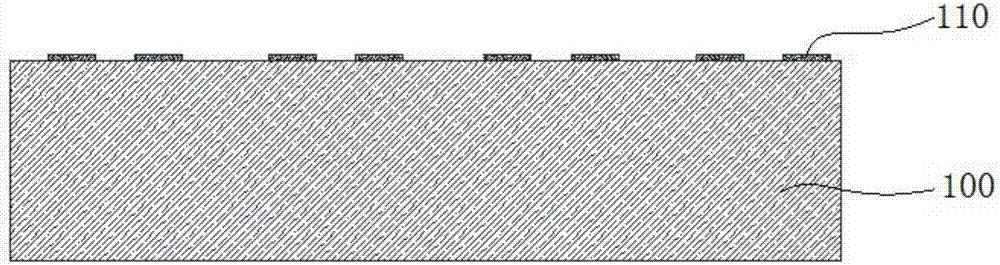

[0031] like image 3 A cross-sectional view of the wafer 100 is shown, and the metal region 110 is the region where the front side of the wafer serves as an electrode;

[0032] like Figure 4 As shown, as in the conventional WLCSP process, metal bumps 120 are first prepared on the front side of the wafer (pillar process).

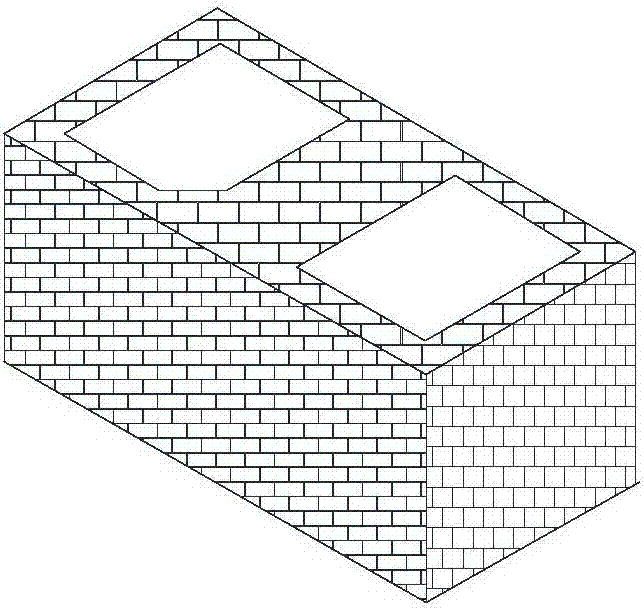

[0033] like Figure 5 As shown, according to the structure of the final TVS product, the wafer is cut to prepare the gap 130, and the depth of the gap is controlled during cutting, and the wafer cannot be cut through;

[0034] The above steps can obtain the aforementioned TVS chip structure for realizing WLCSP six-sided plastic packaging.

[0035] like Image 6 As shown, the plastic encapsulation is completed from the front side of the wafer downward to obtain a front plastic encapsulation 140 covering the gap 130 obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com