Motor stator ventilation structure with rectangular section channel steels

A technology with a rectangular cross-section and a motor stator, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve problems such as unbalanced air flow direction, high stator temperature, and large loss of cooling gas windmilling, etc., to achieve Increased heat dissipation efficiency, improved cooling and heat dissipation capacity, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

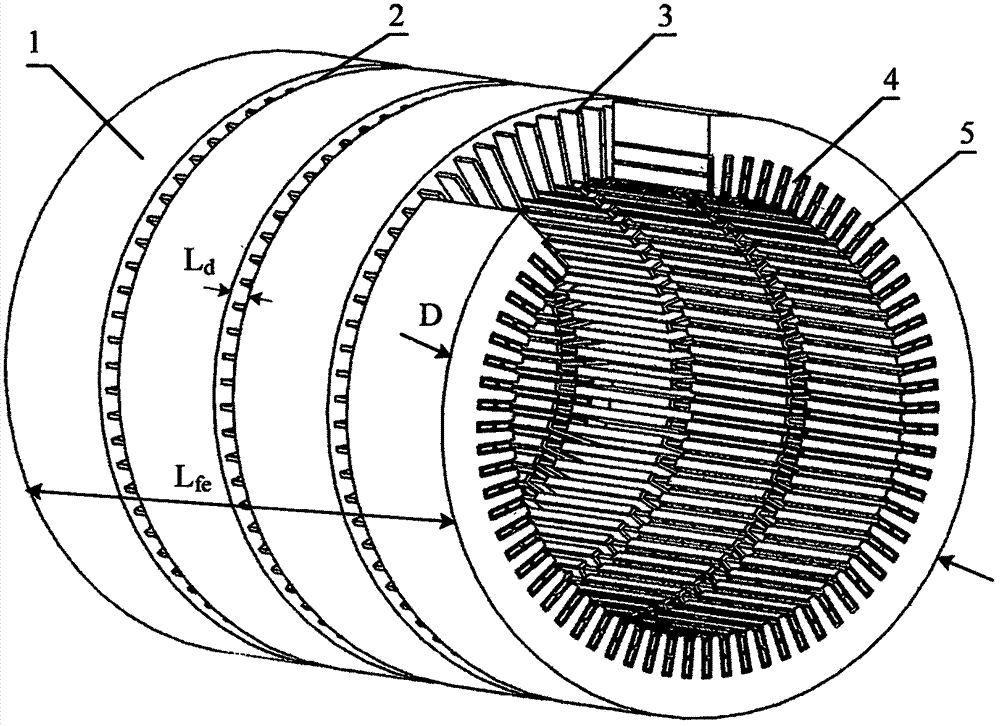

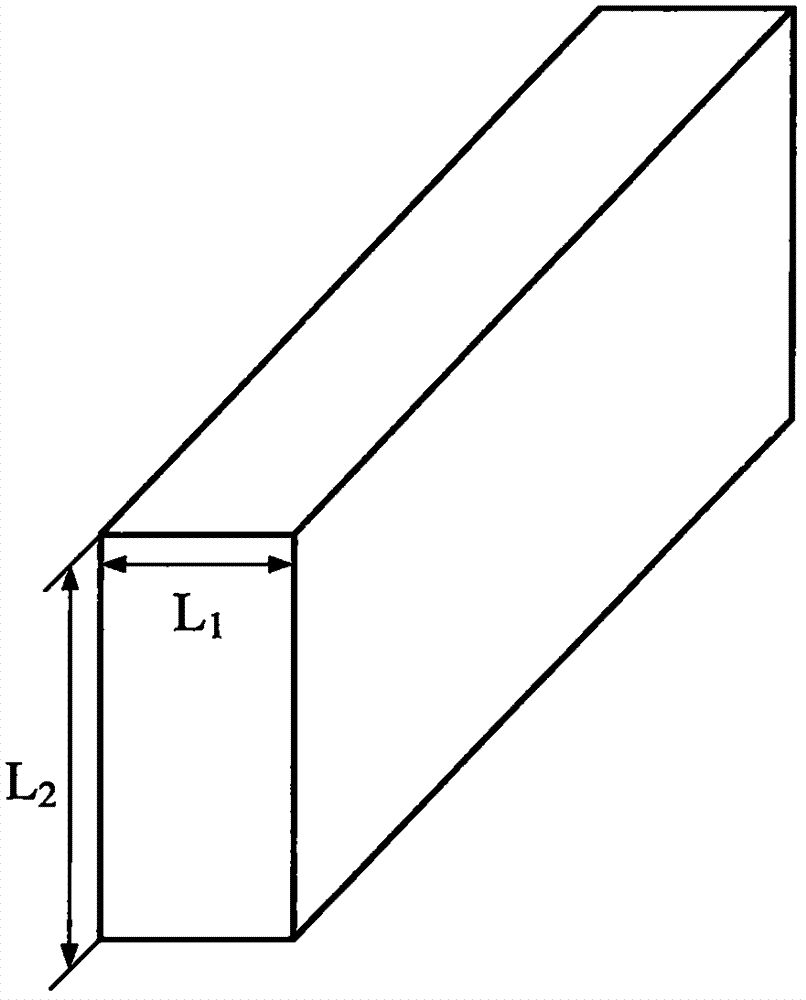

[0019] Motor parameters in the present embodiment: stator core outer diameter D=1260mm, L fe =1340mm, stator tooth width b t =19.3mm, stator tooth height h s = 81.4 mm. Such as figure 1 As shown, the motor stator ventilation structure with a rectangular cross-section channel steel according to the present invention mainly includes a segmented stator core (1), a radial ventilation ditch (2) and a ventilation channel steel (3), wherein the segmented stator core ( 1) Distributed along the axial direction, the number of segments n is determined by the outer diameter of the stator core (1), which is n=D / 55~D / 50, D is the outer diameter of the stator core of the motor, and the adjacent segmented stator core (1) There is a radial ventilation ditch (2) in between, which is formed by ventilation channel steel (3) distributed along the circumference, and the axial width L of the radial ventilation ditch (2) d and motor stator core outer diameter D and axial length L fe related, L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com