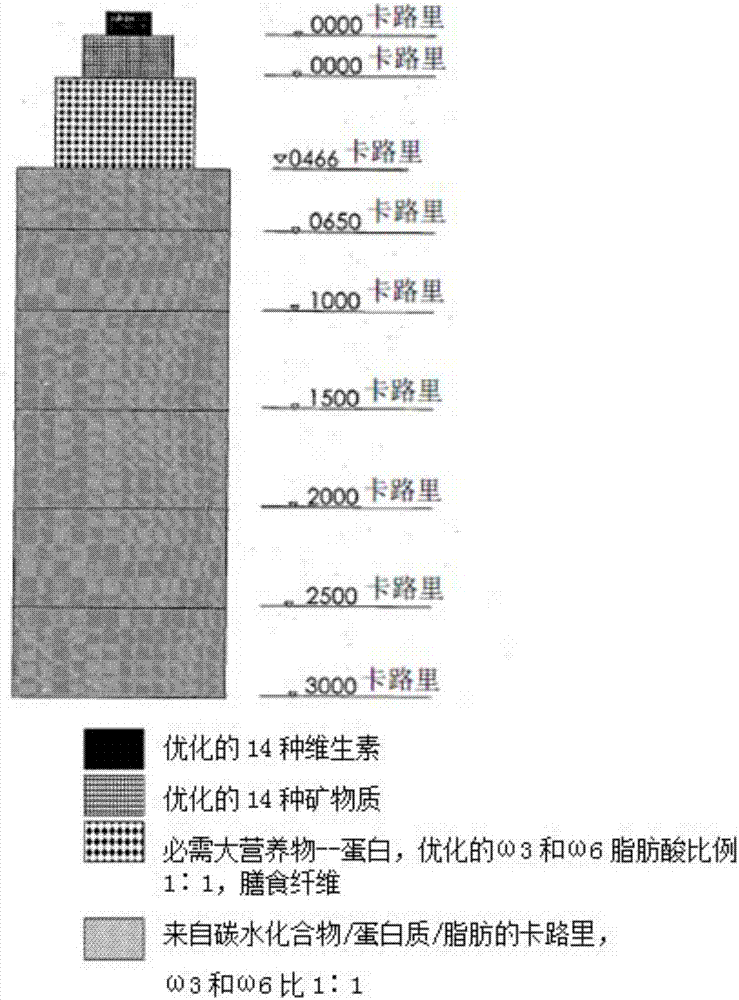

Optimized nutrient food

A technology of nutritious food and seeds, applied in the field of optimized nutritious food, can solve problems such as excessive consumption of marine oil, health risk disorder, blood coagulation mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

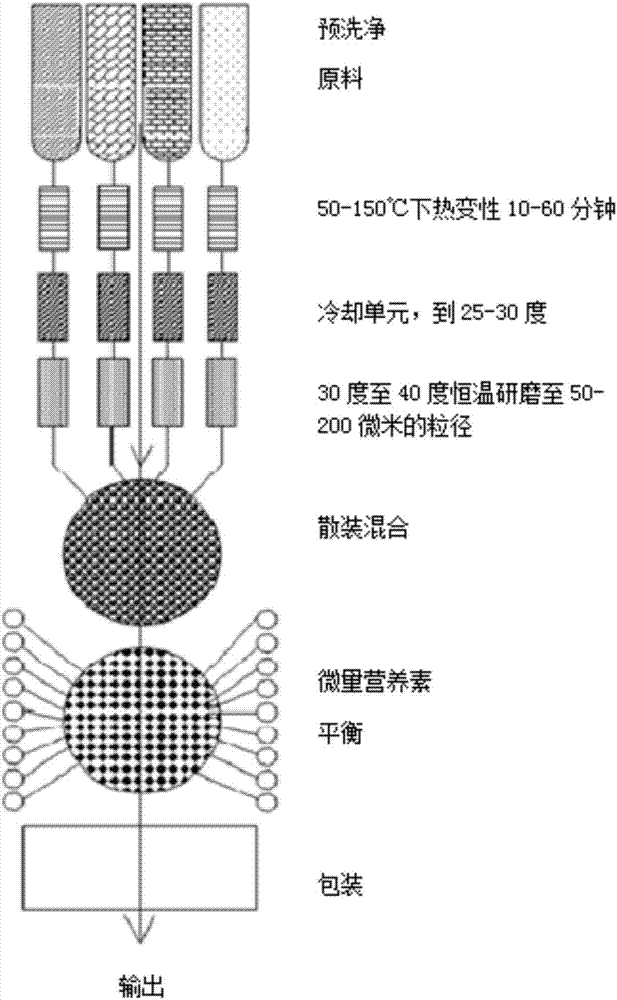

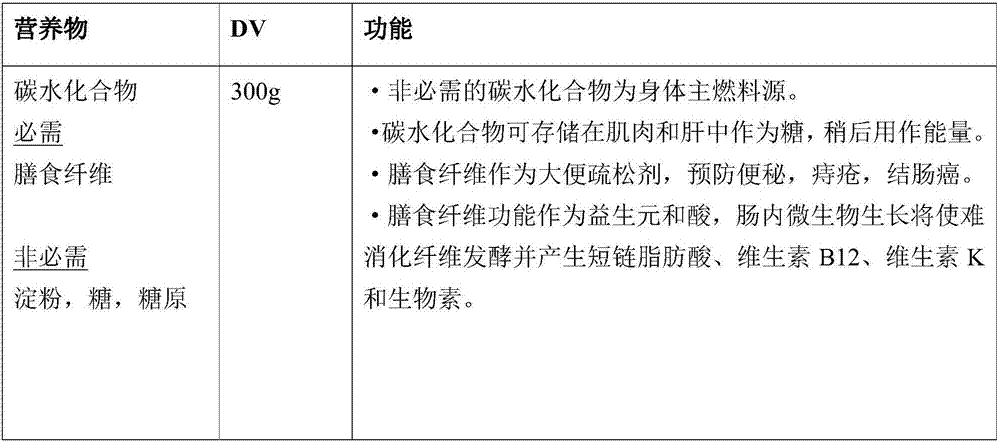

Method used

Image

Examples

Embodiment 1

[0106] According to the laboratory analysis data of each item, the raw materials are selected in consideration of each nutritional content, so as to obtain the nutritional composition of the optimized nutritional food. 90 grams of soybeans, 50 grams of linseeds and 10 grams of ground nuts after deoiling were washed separately to make them free of foreign matters / impurities, then washed with water, and air-dried. Washed soybeans are gradually heated to a temperature of about 150°C for about 30 minutes, washed linseeds are gradually heated to a temperature of about 100°C for about 20 minutes, deoiled ground nuts are gradually heated to a temperature of about 120°C temperature for about 20 minutes to obtain a denatured dehydrated product. The resulting denatured dehydrated product is individually cooled to about 25-30°C; independently ground into fine and coarse particles with a particle size of less than 200 microns while maintaining the temperature at 30-40°C. The ground powde...

Embodiment 2

[0110] According to the laboratory analysis data of each item, the raw materials are selected in consideration of each nutritional content, so as to obtain the nutritional composition of the optimized nutritional food. 60g of winged beans, 60g of cane seeds, and 30g of deoiled watermelon seeds were washed separately to make them free of foreign matters / impurities, then washed with water, and air-dried. After cleaning, the winged beans are gradually heated and cleaned at a temperature of about 150°C for about 30 minutes, and the washed cane seeds are gradually heated at a temperature of about 120°C for about 20 minutes, and the washed deoiled watermelon seeds are heated at a temperature of about 120°C Gradually heated for about 10 minutes to obtain a denatured dehydrated product. The resulting denatured dehydrated product is individually cooled to about 25-30°C; independently ground into fine and coarse particles with a particle size of less than 200 microns while maintaining t...

Embodiment 3

[0114] According to the laboratory analysis data of each item, the raw materials are selected in consideration of each nutritional content, so as to obtain the nutritional composition of the optimized nutritional food. 80 grams of hemp seeds, 40 grams of perilla seeds, and 30 grams of deoiled soybeans were washed separately to make them free of foreign matter or impurities, then washed with water and air-dried. Heat the washed hemp seeds gradually at a temperature of about 100°C for about 10 minutes, wash the perilla seeds at a temperature of about 100°C for about 10 minutes, and wash the deoiled soybeans at a temperature of about 120°C It was gradually heated for about 10 minutes to obtain a denatured and dehydrated product. The resulting denatured dehydrated product is cooled to about 25-30°C; independently ground into fine and coarse particles with a particle size of less than 200 microns while maintaining the temperature at 30-40°C. The ground powder obtained in this way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com