Waste treatment process for a fossil-fuel extraction site

A technology for waste treatment and fossil fuels, applied in mining wastewater treatment, chemical instruments and methods, mining fluids, etc., can solve problems such as high cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

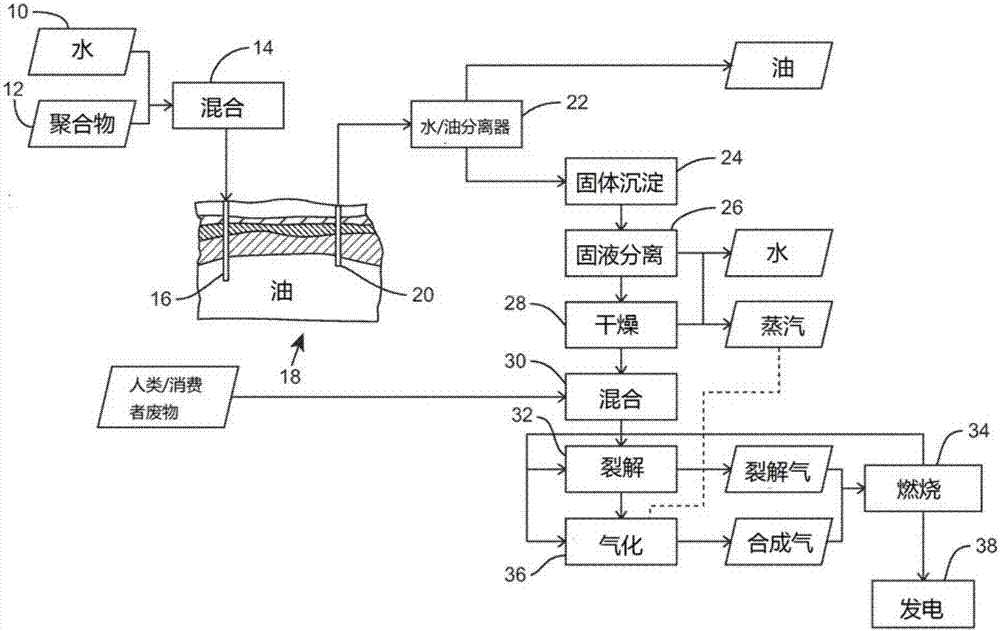

[0026] figure 1 Shown is the enhanced oil recovery (EOR) polymer flooding process for Field 18 and the waste treatment process of the present invention for treating produced water and oil from EOR.

[0027] In a polymer flooding process, water from a water source 10 and polymer from a polymer source 12 are mixed in a mixing step 14 and injected into an oil reservoir in an oil field 18 via an injection well 16 . The polymer is selected from polymers with long chain macromolecules, which when mixed with water form a high viscosity solution. In the illustrated embodiment, the polymer is polyacrylamide "PAM" (or hydrolyzable polyacrylamide HMPA), but in other embodiments any suitable material may be chosen. In a typical enhanced oil recovery (EOR) process, the polymeric material is present in solution at 5-10% by weight.

[0028] The lower end of the injection well 16 is located in the oil reservoir of the oil field 18, so that the solution of water and polymer injected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com