Method for producing connected body, method for connecting electronic parts, connected body

A manufacturing method and technology of electronic components, applied in adhesive heating bonding method, semiconductor/solid-state device manufacturing, bonding method, etc., can solve high thermal pressing temperature, uneven display, large thermal shock, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

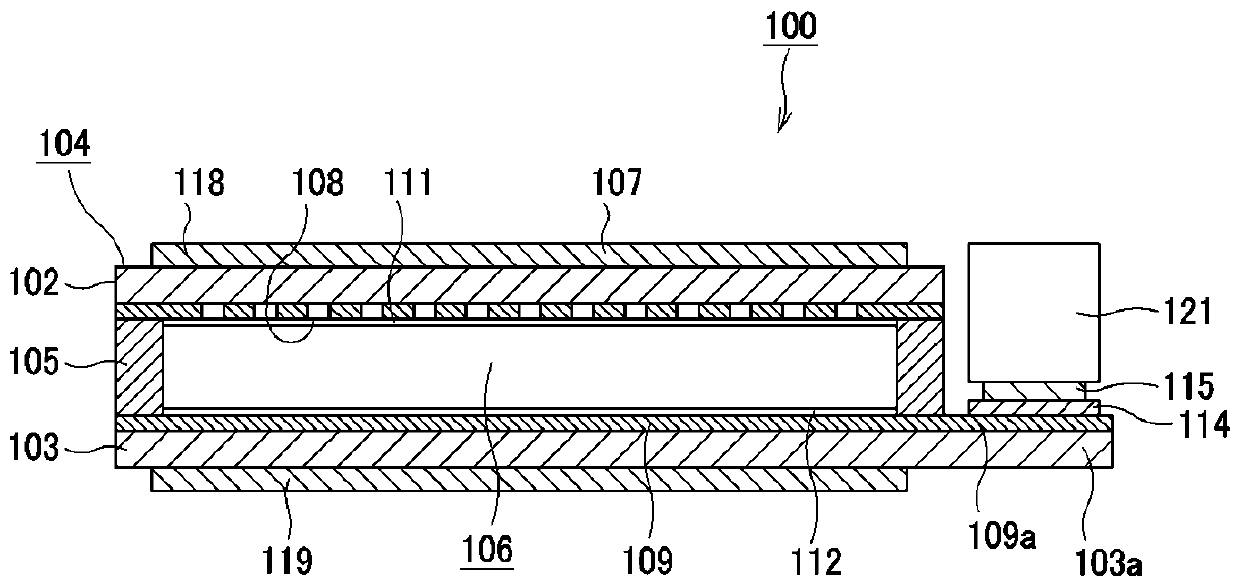

[0048] In the following first embodiment, a case of so-called COG (chip on glass) mounting in which an IC chip for driving a liquid crystal is mounted as an electronic component on a glass substrate of a liquid crystal display panel will be described as an example. The liquid crystal display panel 10, such as figure 1 As shown, two transparent substrates 11 , 12 made of glass substrates or the like are arranged facing each other, and these transparent substrates 11 , 12 are bonded to each other by a frame-shaped sealing material 13 . Further, in the liquid crystal display panel 10 , a panel display portion 15 is formed by enclosing liquid crystal 14 in a space surrounded by the transparent substrates 11 and 12 .

[0049] A pair of stripe-shaped transparent electrodes 16 and 17 made of ITO (indium tin oxide) or the like are formed on both inner surfaces of the transparent substrates 11 and 12 facing each other so as to cross each other. Then, the two transparent electrodes 16...

specific example 1-1

[0069] [Temporary pasting process]

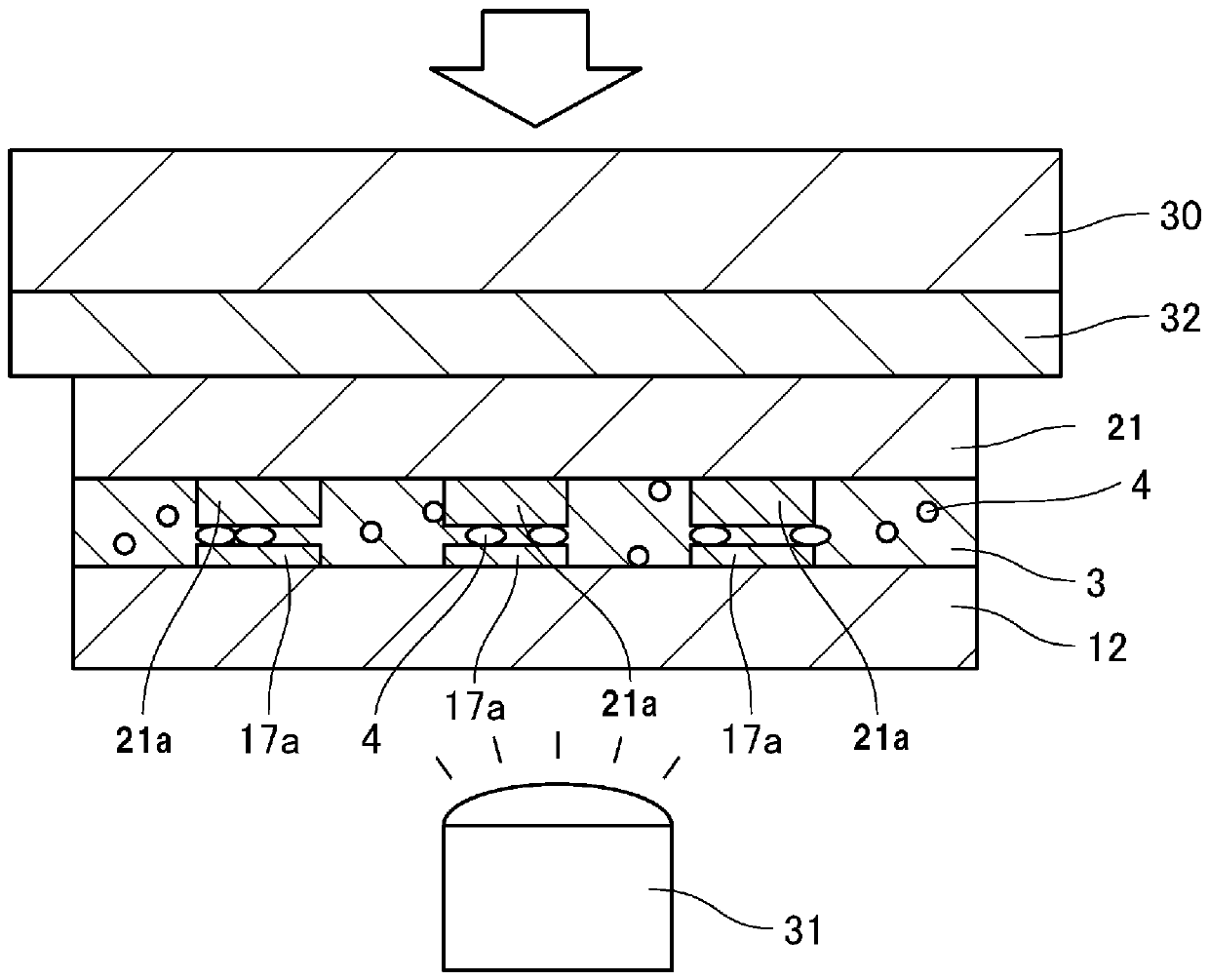

[0070] First, the anisotropic conductive film 1 is temporarily pasted on the transparent substrate 12 (adhesive placement step). A method of temporarily pasting an anisotropic conductive film such as image 3 As shown, the anisotropic conductive film 1 is disposed on the transparent electrode 17 of the transparent substrate 12 so that the adhesive resin layer 3 faces the transparent electrode 17 side. After disposing the adhesive resin layer 3 on the transparent electrode 17, heat and press the adhesive resin layer 3 from the release film 2 side with a thermocompression bonding tool, for example, to separate the thermocompression bonding tool from the release film 2. , the release film 2 is peeled from the adhesive resin layer 3 . In addition, the temporary bonding of the anisotropic conductive film 1 may be performed by pressurization and light irradiation of a thermocompression bonding tool, and may be performed using thermocompression ...

specific example 1-2

[0086] In this manufacturing method, ultraviolet irradiation may be performed from the IC 18 side for liquid crystal driving instead of the ultraviolet irradiation from the transparent substrate 12 side in the temporary pressure-bonding process described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com