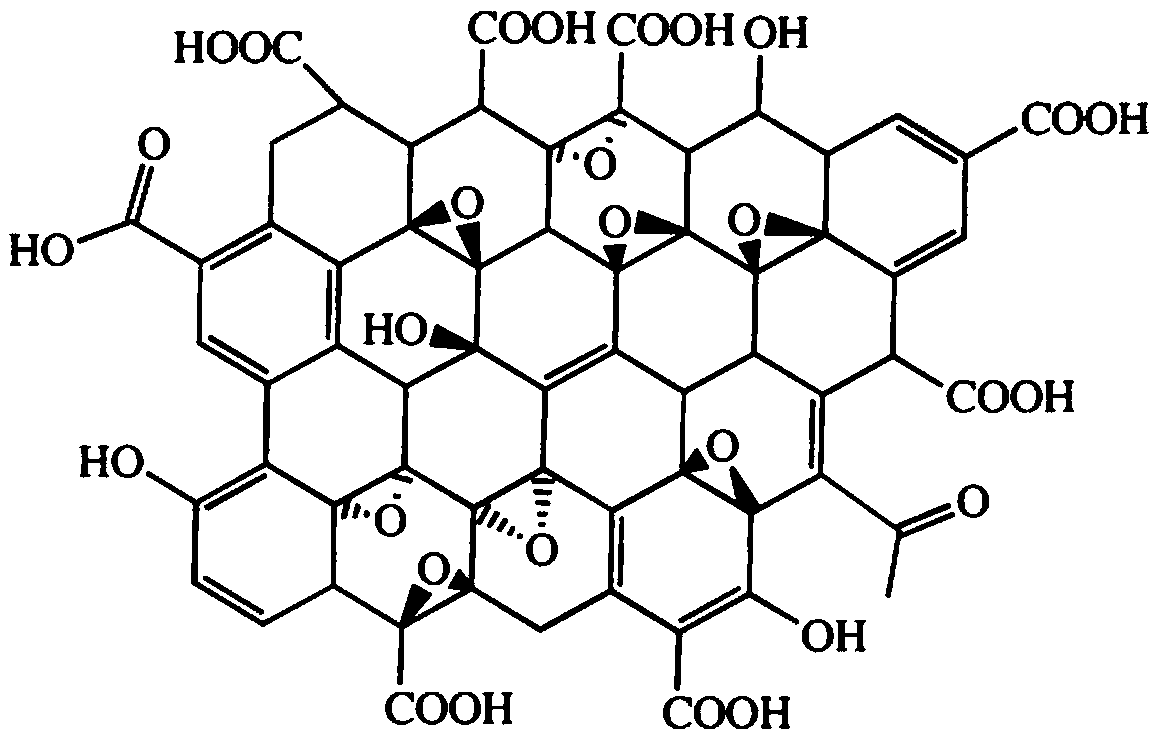

Carboxyl modified graphene oxide modified rubber asphalt mixture and preparation method thereof

A technology of asphalt mixture and carboxyl group modification, applied in the field of road engineering, can solve the problems of high viscosity of rubber asphalt, poor high temperature performance, reduced high temperature performance, etc., and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

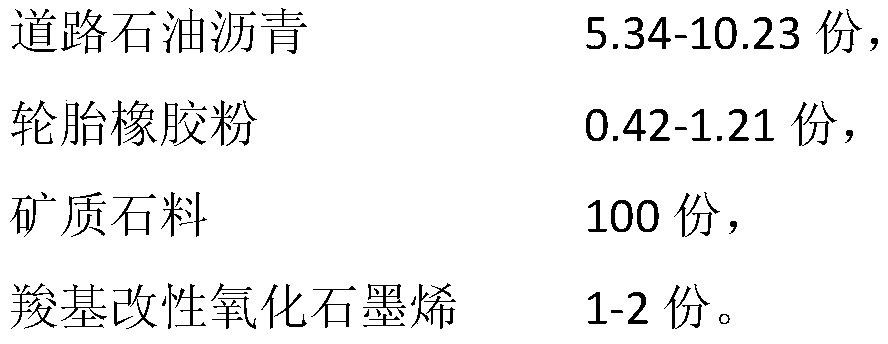

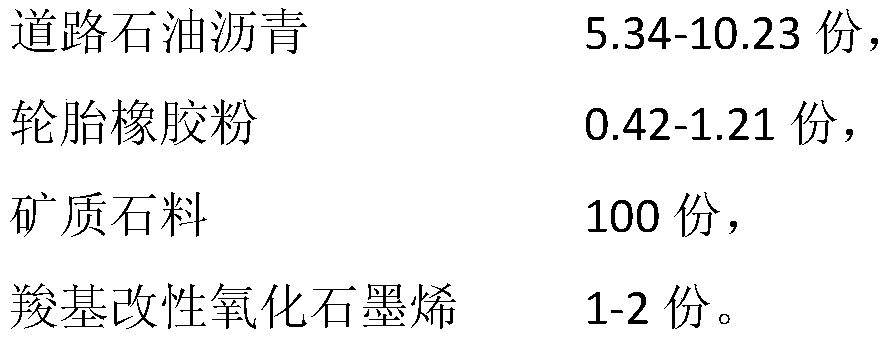

[0046] A kind of preparation method of above-mentioned carboxy-modified graphene oxide modified rubber asphalt mixture, it comprises the steps:

[0047] (1) Add 0.42-1.21 parts of tire rubber powder to 5.34-10.23 parts of road petroleum asphalt, and stir at the first temperature to obtain rubber asphalt;

[0048](2), heating 100 parts of mineral stones to the second temperature, then adding 1-2 parts of carboxyl-modified graphene oxide, and stirring to obtain a mixture;

[0049] (3) Add 6-11 parts of rubber asphalt to the mixture, and stir to obtain carboxyl-modified graphene oxide-modified rubber asphalt mixture.

[0050] In fact, rubber asphalt is component A, and its total mass is 100 parts, of which, the quality of tire rubber powder is 7-11 parts, and the quality of petroleum asphalt is 89-93 parts; mineral stone is component B, and its total mass For 100 parts, component A accounts for 6‐11% of component B.

[0051] Wherein, in step (1), tire rubber powder actually acc...

Embodiment 1

[0059] The preparation method of the carboxyl-modified graphene oxide modified rubber asphalt mixture of the present embodiment comprises the steps:

[0060] (1), 0.42 parts of tire rubber powder were added to 5.58 parts of 70# road petroleum asphalt, and at the first temperature of 180 ° C, stirred and reacted for 45 minutes to obtain rubber asphalt, wherein the mass percentage of tire rubber powder actually accounted for rubber asphalt was 7%, road petroleum asphalt actually accounts for 93% of the mass percentage of rubber asphalt;

[0061] (2), heating 100 parts of mineral stones to a second temperature of 160°C, then adding 1 part of carboxy-modified graphene oxide, and stirring to obtain a mixture;

[0062] (3), add 6 parts of above-mentioned rubber asphalt in above-mentioned mixture, stir to obtain carboxyl-modified graphene oxide modified rubber-asphalt mixture.

[0063] Among them, when the sieve size is 16.0mm, the sieve pass rate of the mineral stone is 100%.

[0...

Embodiment 2

[0073] The preparation method of the carboxyl-modified graphene oxide modified rubber asphalt mixture of the present embodiment comprises the steps:

[0074] (1) Add 1.1 parts of tire rubber powder to 8.9 parts of road petroleum asphalt, and at the first temperature of 200°C, stir and react for 45 minutes to obtain rubber asphalt, wherein the tire rubber powder actually accounts for 11% by mass of the rubber asphalt , road petroleum asphalt actually accounts for 89% of the mass percentage of rubber asphalt;

[0075] (2), heating 100 parts of mineral stones to a second temperature of 200°C, then adding 1.5 parts of carboxyl-modified graphene oxide, and stirring to obtain a mixture;

[0076] (3), add 10 parts of above-mentioned rubber asphalt in above-mentioned mixture, stir to obtain carboxyl-modified graphene oxide modified rubber-asphalt mixture.

[0077] Among them, when the sieve size is 16.0mm, the sieve pass rate of the mineral stone is 100%.

[0078] When the sieve siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com