Method and device for controlling cell concentration uniformity

A cell concentration and control device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of air mixing, easy rupture of cell membrane, and not too large, etc., to increase flow The effect of simple channel path, simple imaging structure, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

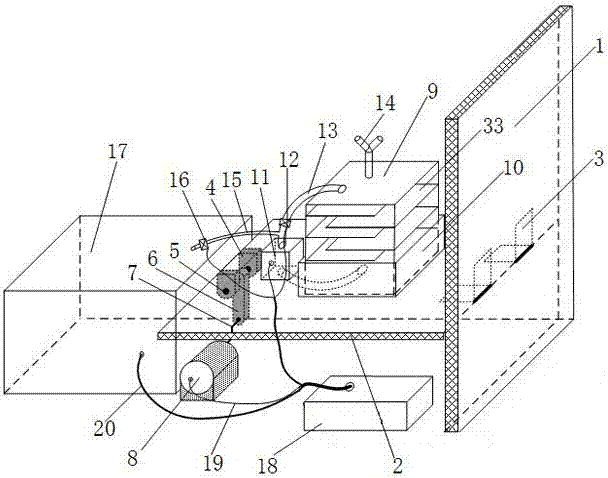

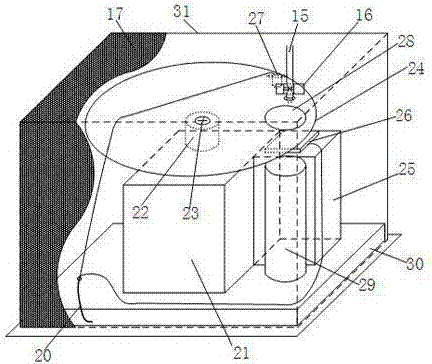

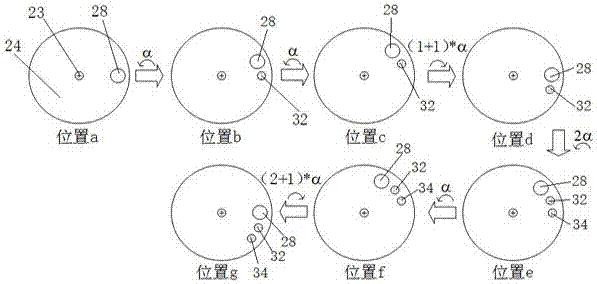

[0025] see figure 1 , a cell concentration uniformity control device of the present invention comprises a vibrating table bottom plate 2, the vibrating table bottom plate 2 is arranged horizontally, and one side of the vibrating table bottom plate is fixed on the wall 1 with a hinge 3, so that the fixed vibrating table bottom plate 2 can take the side edge as The center of the circle rotates. A vibrating table hinge seat 4 is installed under the other side of the vibration table base plate 2, a horizontal hinge shaft 5 is fixed on the hinge seat 4, the upper end of the connecting piece 6 is vacantly sleeved on the hinge shaft 5, and the lower end of the connecting piece 6 is hinged to one end of the crank 7 , the other end of the crank 7 is coaxially connected with the rotary motor 8 . The upper end of the connecting piece 6 can rotate up and down with the hinge shaft 5 as the center of circle. The rotating motor 8 is placed under the bottom plate 2 of the vibrating table. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com