Axial flow fan stationary blade noise reduction structure based on memory alloy

A memory alloy, axial flow fan technology, applied to the components of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve problems such as poor noise reduction effect, and achieve simple structure and high control accuracy. , to ensure consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

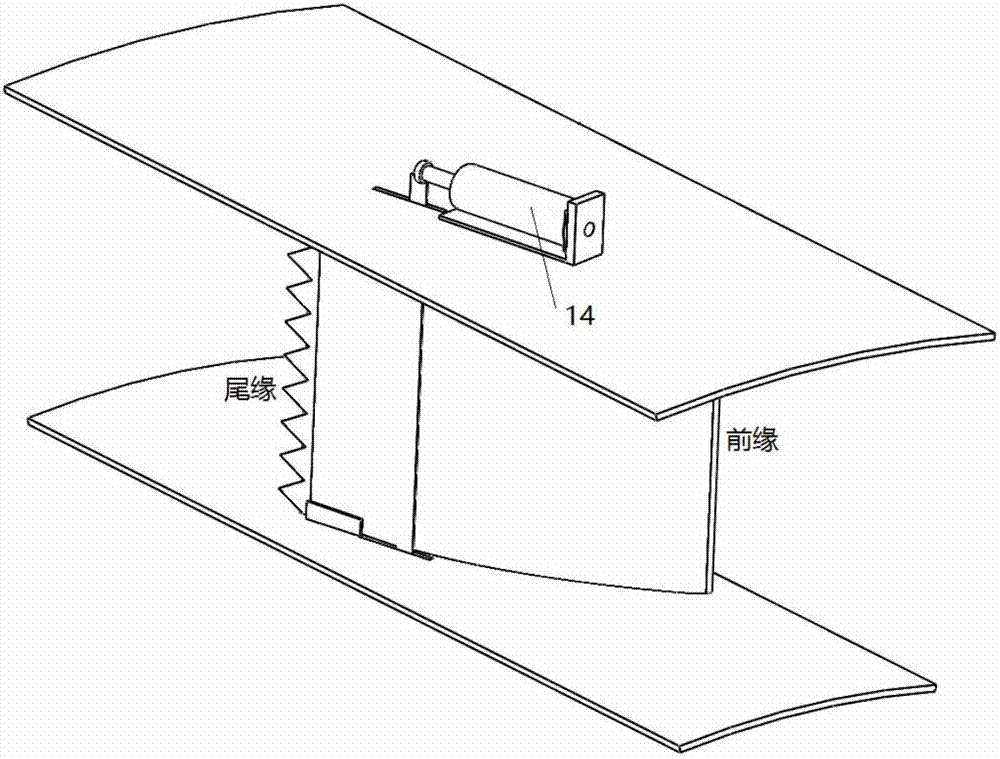

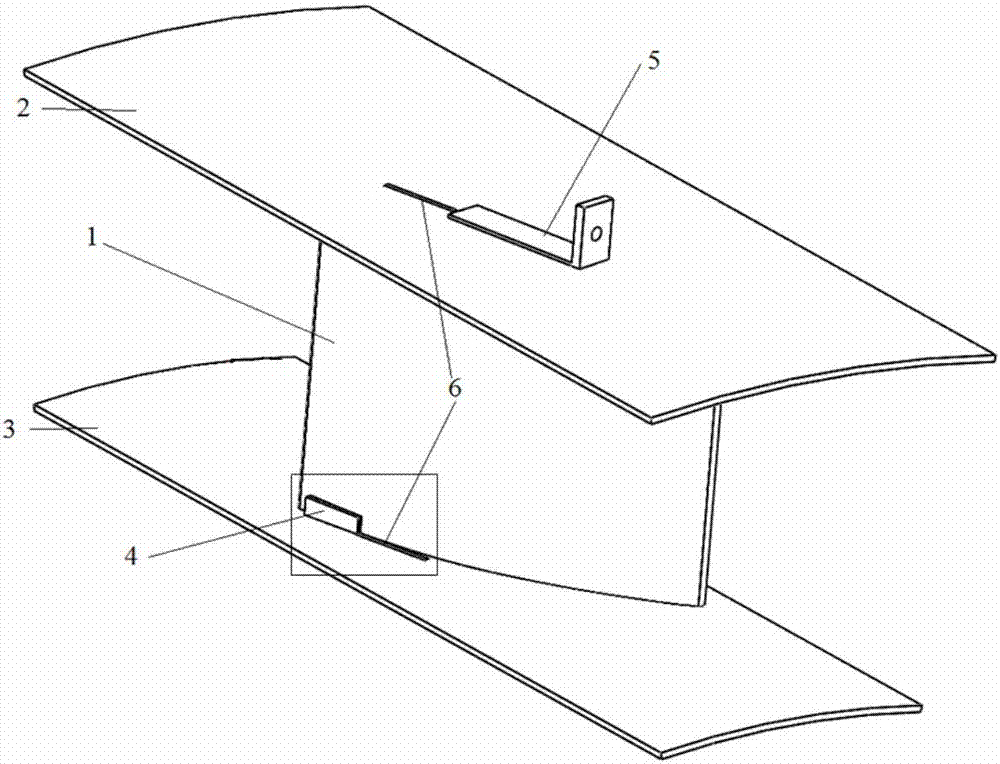

[0026] This embodiment is a noise-reducing structure for stator blades of an axial flow fan based on a memory alloy.

[0027] In this embodiment, the principle of breaking the shedding vortex by means of the sawtooth slider on the trailing edge is used to reduce the noise at the trailing edge of the stator vane of the axial flow fan. Through the memory alloy driver, the adjustment of the sawtooth slider on the trailing edge is realized, so that it is similar to the width of the wake at different speeds, and then the trailing edge noise of the stator blade of the axial flow fan is controlled to the minimum.

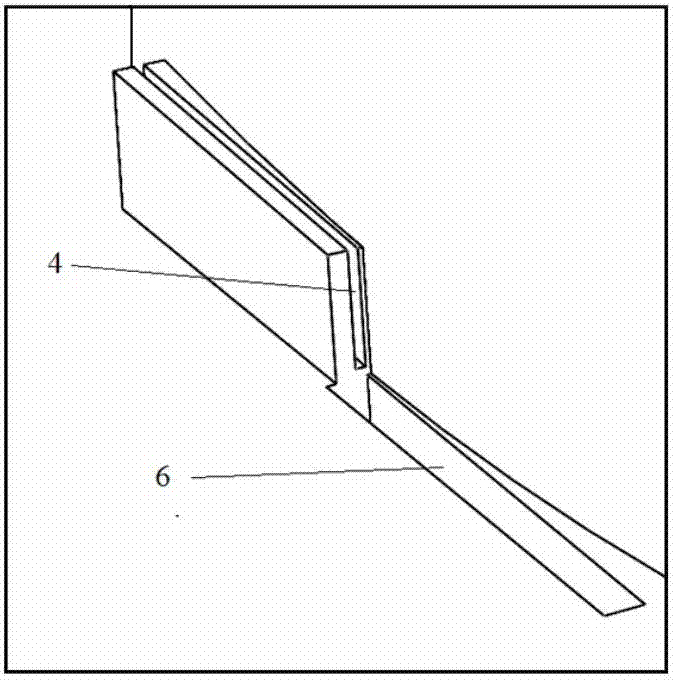

[0028] refer to Figure 1 to Figure 5 , this embodiment is based on memory alloy axial flow fan stator blade noise reduction structure, which is connected by stator blade 1, casing 2, wheel hub 3, chute 4, installation base 5, channel 6, trailing edge sawtooth slider 7, Rod 8, connecting ring 9 and memory alloy driver; wherein, the stator blade 1 is a hollow thick blade o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com