Anti-vibration pad for whole-body vibration

A shock-absorbing pad, whole body technology, applied in the direction of spring/shock absorber, mechanical equipment, low internal friction spring, etc. Vibration effect is not clear and other problems, to meet the installation and daily maintenance, reduce the level of whole body vibration, good ease of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

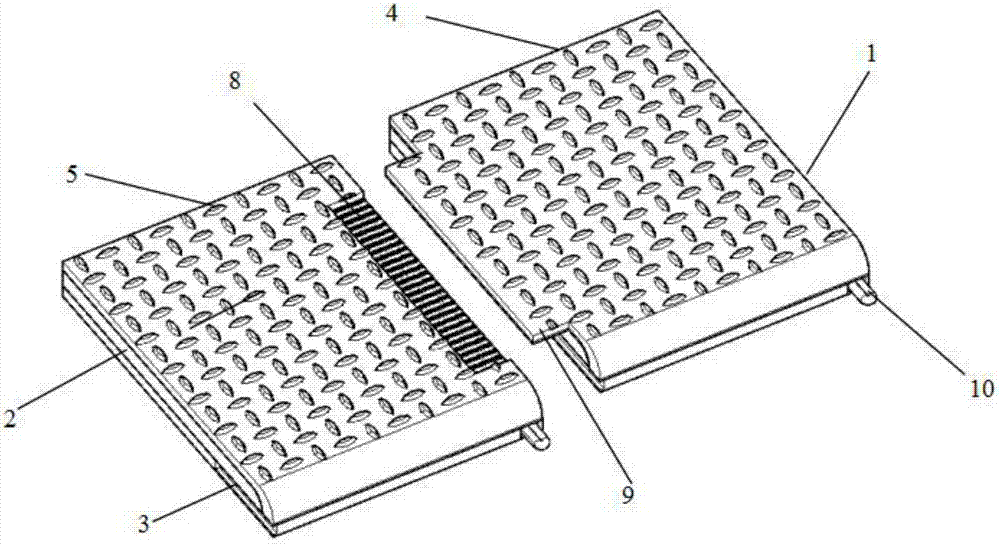

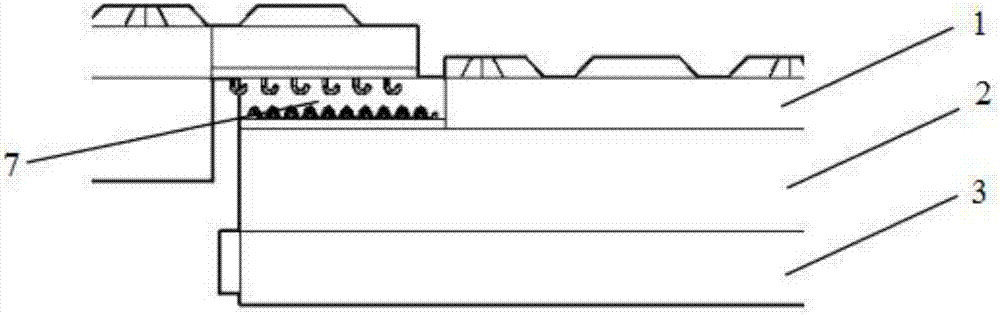

[0037] refer to figure 1 , figure 2 and image 3 , the present embodiment provides a whole-body vibration damping pad, which is characterized in that it includes a wear-resistant layer 1 on the top layer, a vibration-damping layer 2 on the middle layer, and an anti-skid layer 3 on the bottom layer connected in sequence; 1 is provided with a non-slip textured surface 4, and the shock-absorbing layer 2 is made of expanded polystyrene. The anti-slip texture surface 4 is an anti-slip protrusion 5 cast and carved on the wear-resistant layer 1, and of course it can also be designed as an anti-slip groove concave inward in structure. The whole body vibration damping pad of the present embodiment also includes a Velcro splicing assembly 7 and a hidden lifting belt 10. The Velcro splicing assembly 7 includes an adhesive surface part 8 and a matte surface part 9 matching the adhesive surface part 8. The hidden lifting The belt 10 is installed on the anti-slip layer 3 on the side fac...

Embodiment 2

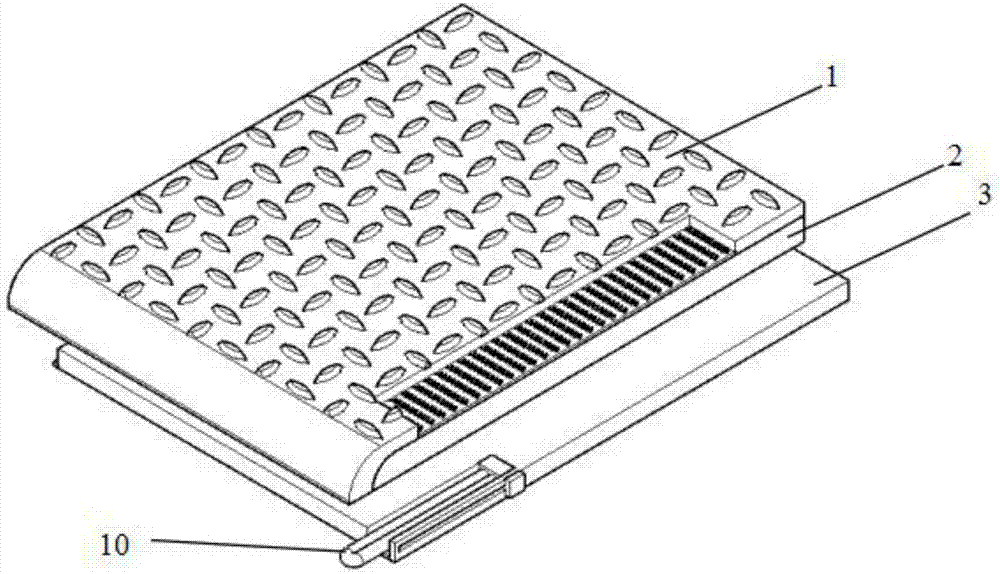

[0059] refer to Figure 4 , this embodiment provides another whole-body vibration damping pad, the structure of which is roughly the same as that provided in Embodiment 1, the difference lies in that the same distance and the same direction row are interposed between the wear-resistant layer 1 and the vibration-damping layer 2 The damping conduction strip 6 of the cloth, the damping conduction strip 6 is a rubber strip.

Embodiment 3

[0061] This embodiment provides another whole-body vibration damping pad, the structure of which is roughly the same as that provided in Embodiment 2, the difference lies in that the damping layer 2 and the anti-slip layer 3 are interposed with equidistant and in the same direction. The vibration-damping conductive strip 6 is a strip-shaped cavity formed between two adjacent layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com