Equipment failure prediction method under cloud manufacturing

A technology for equipment failure and prediction methods, which is applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., to achieve the effects of reducing economic losses, improving prediction speed, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment (taking cutting machine equipment as example)

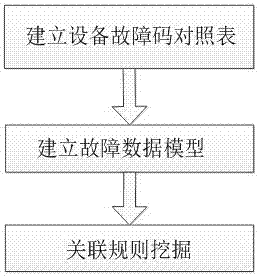

[0019] 1. Equipment failure prediction method under cloud manufacturing. Include the following steps:

[0020] Step 1: Analyze the structure and working principle of the glass cutting machine. The glass cutting machine consists of three parts: cutting table, cutting bridge and computer control box, as follows Figure 4 As shown, it mainly includes: 1 represents the wool felt gasket. 2 means beam. 3 represents the transverse transmission guide rail. 4 represents the cutter head. 5 represents longitudinal transmission guide rail. 6 represents a driving motor. 7 represents a conveyor belt. 8 represents the horizontal feed conveying system. 9 represents a cable crawler. 10 represents the longitudinal feed transmission system.

[0021] Step 2: Create a fault signature code comparison table for the cutting machine.

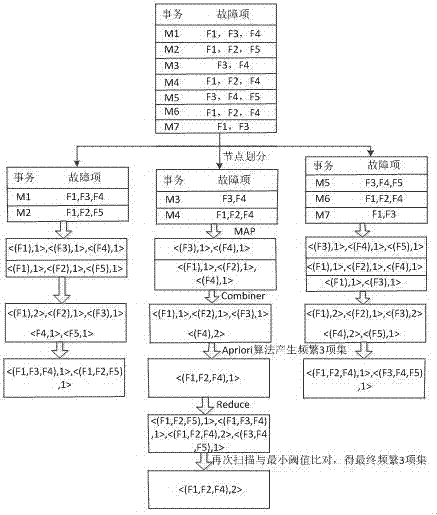

[0022] The present invention adopts Hadoop distributed file system HDFS, combines with Map...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com