Detection method for sulfur-containing inclusions in steel

A detection method and technology for inclusions, which are applied in the field of iron and steel metallurgy continuous casting production quality detection, can solve the problems affecting the collection and sample preparation observation of inclusions, slow filtration, and high toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

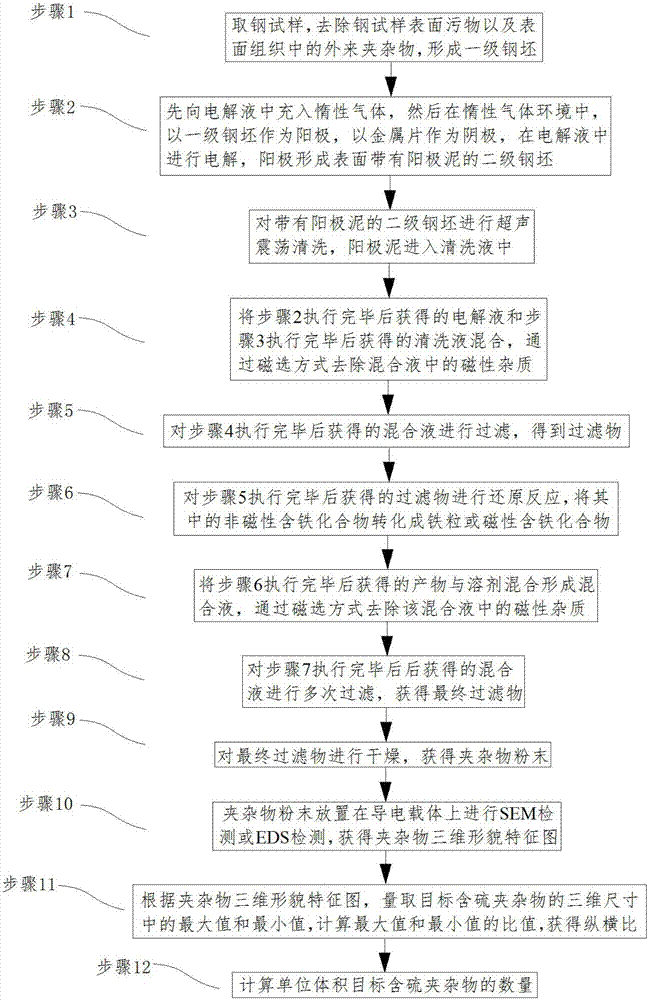

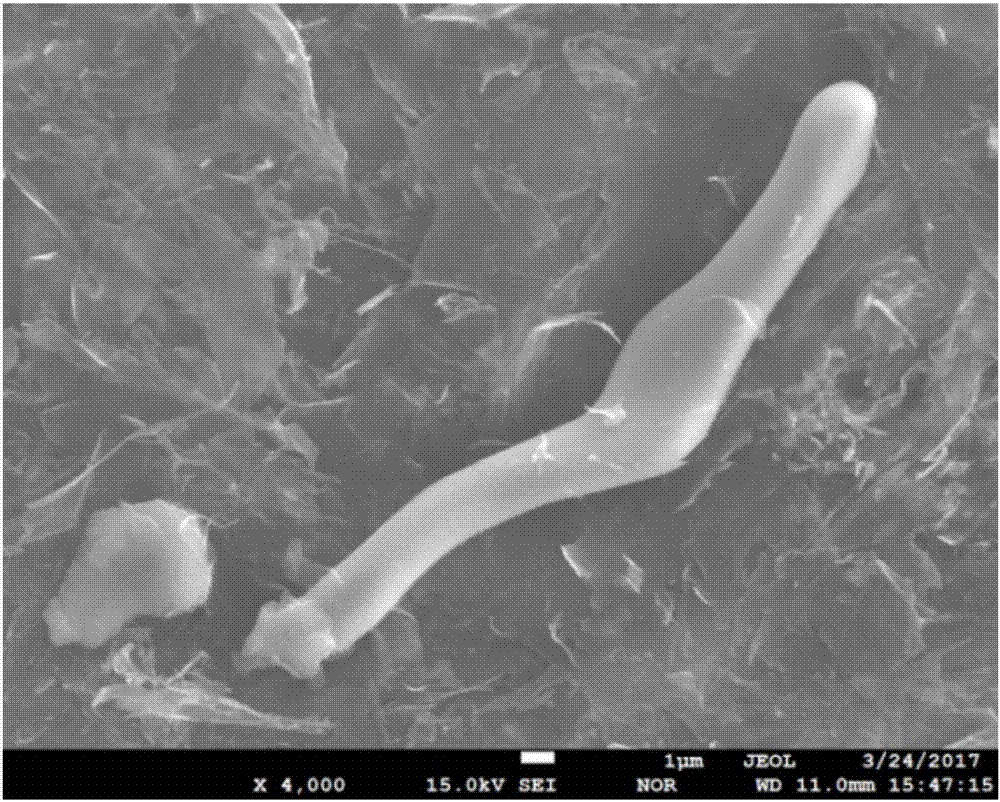

[0036] refer to figure 1 , In this embodiment, a method for detecting sulfur-containing inclusions in steel is provided. In this embodiment, the target sulfur-containing inclusion detected is MnS, and the influence of MnS on the quality of steel products can be studied. But not limited thereto, in other embodiments, the target sulfur-containing inclusions can also be CuS, Cu 2 Other sulfur-containing inclusions contained in steel such as S are used for other follow-up studies.

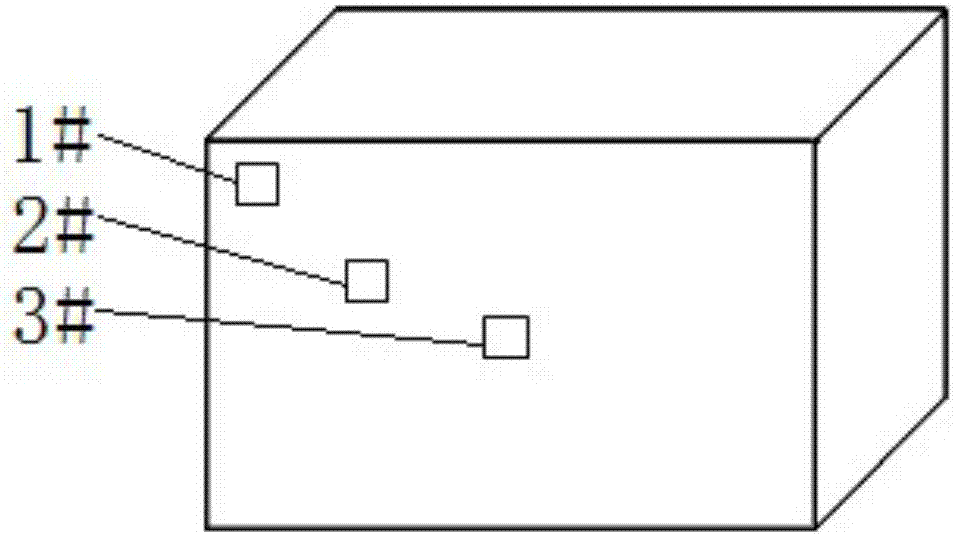

[0037] Specifically, in this embodiment, U75V heavy rail steel is tested, referring to figure 2 , it is planned to take three steel samples from different grain regions, respectively numbered 1#, 2#, 3#, and carry out the following steps 1-10 for each steel sample:

[0038] Step 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com