Method for measuring sand content of sludge

A technology of sand content and sludge, applied in the field of detection, to achieve the effect of safe and simple experiment, mild condition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for measuring the sand content of sludge, comprising the steps of:

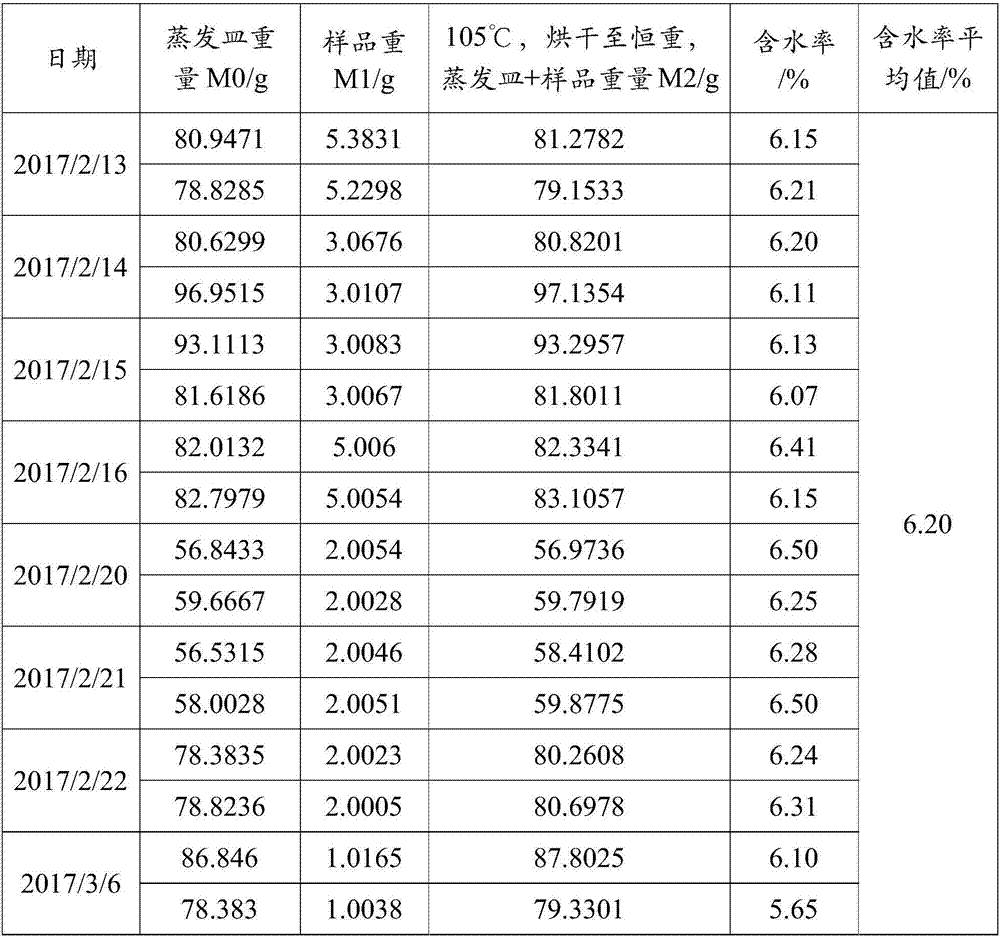

[0041] (1) Sludge pretreatment: Dry the sludge produced by the sewage treatment plant and measure its moisture content; among them, during the sludge pretreatment, the operator wears a mask to operate.

[0042] (2) Burning: Accurately weigh the dried sludge and burn it in a muffle furnace to constant weight.

[0043] (3) Reaction: Add concentrated hydrochloric acid to the sludge burned to constant weight, and heat in a water bath for reaction. Wherein, the temperature of the water bath is 80° C., and the time of the water bath is 10 min.

[0044] (4) Filtration: filter the reacted solution with quantitative filter paper, and fully wash the filter residue with deionized water.

[0045] (5) Burn again: put the filter residue and the quantitative filter paper in a muffle furnace and burn to constant weight to obtain pure sand.

[0046] (6) Calculation: The sand content of the sludge is obtaine...

Embodiment 2

[0048] A method for measuring the sand content of sludge, comprising the steps of:

[0049] (1) Sludge pretreatment: Dry the sludge produced by the sewage treatment plant and measure its moisture content; among them, during the sludge pretreatment, the operator wears a mask to operate.

[0050] (2) Burning: Accurately weigh the dried sludge and burn it in a muffle furnace to constant weight.

[0051] (3) Reaction: Add concentrated hydrochloric acid to the sludge burned to constant weight, and heat in a water bath for reaction. Wherein, the temperature of the water bath is 100° C., and the time of the water bath is 15 minutes.

[0052] (4) Filtration: filter the reacted solution with quantitative filter paper, and fully wash the filter residue with deionized water.

[0053] (5) Burn again: put the filter residue and the quantitative filter paper in a muffle furnace and burn to constant weight to obtain pure sand.

[0054] (6) Calculation: Obtain the sand content of the sludge ...

Embodiment 3

[0056] A method for measuring the sand content of sludge, comprising the steps of:

[0057] (1) Sludge pretreatment: Dry the sludge produced by the sewage treatment plant and measure its moisture content; among them, during the sludge pretreatment, the operator wears a mask to operate.

[0058] (2) Burning: Accurately weigh the dried sludge and burn it in a muffle furnace to constant weight.

[0059] (3) Reaction: Add concentrated hydrochloric acid to the sludge burned to constant weight, and heat in a water bath for reaction. Wherein, the temperature of the water bath is 90° C., and the time of the water bath is 12 minutes.

[0060] (4) Filtration: filter the reacted solution with quantitative filter paper, and fully wash the filter residue with deionized water.

[0061] (5) Burn again: put the filter residue and the quantitative filter paper in a muffle furnace and burn to constant weight to obtain pure sand.

[0062] (6) Calculation: Obtain the sand content of the sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com