Voltage resisting type isolation transformer box of traction substation

An isolation transformer, traction substation technology, applied in distribution substations, substation/switch layout details, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the damage of DC power equipment, control and protect equipment and DC power supply equipment damage, insulation breakdown and other problems, to achieve the effect of eliminating overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

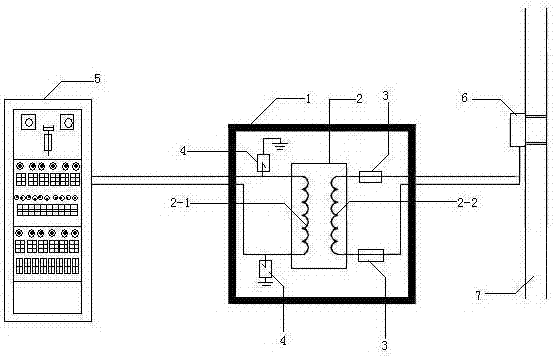

[0017] figure 1 As shown in , the voltage-resistant isolation transformer box of the traction substation is composed of a box body 1, a voltage-resistant isolation transformer 2, a fuse 3, and a surge protector 4. The fuse 3 and the surge protector 4 have the same Two of them, pressure-resistant isolation transformer 2, fuse 3, and surge protector 4 are installed in the box body 1, and the primary side 2-1 of the voltage-resistant isolation transformer is respectively connected to the low-voltage distribution of the traction substation. The two ends of the power output of the electric cabinet 5 are connected by wires, one end of the two surge protectors 4 is respectively connected to the two ends of the primary side 2-1 of the withstand voltage isolation transformer by wires, and the other ends of the two surge protectors 4 are respectively connected to the The box body 1 is connected by wires, one end of the two fuses 3 is respectively connected to the secondary side 2-2 powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com