Control method of elevator lifting safety protection system

A technology of safety protection and control methods, applied in elevators, transportation and packaging, etc., can solve problems such as loss of function of tensioning devices, major electrical failures, fatigue damage to outer rubber, and avoid lengthy effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

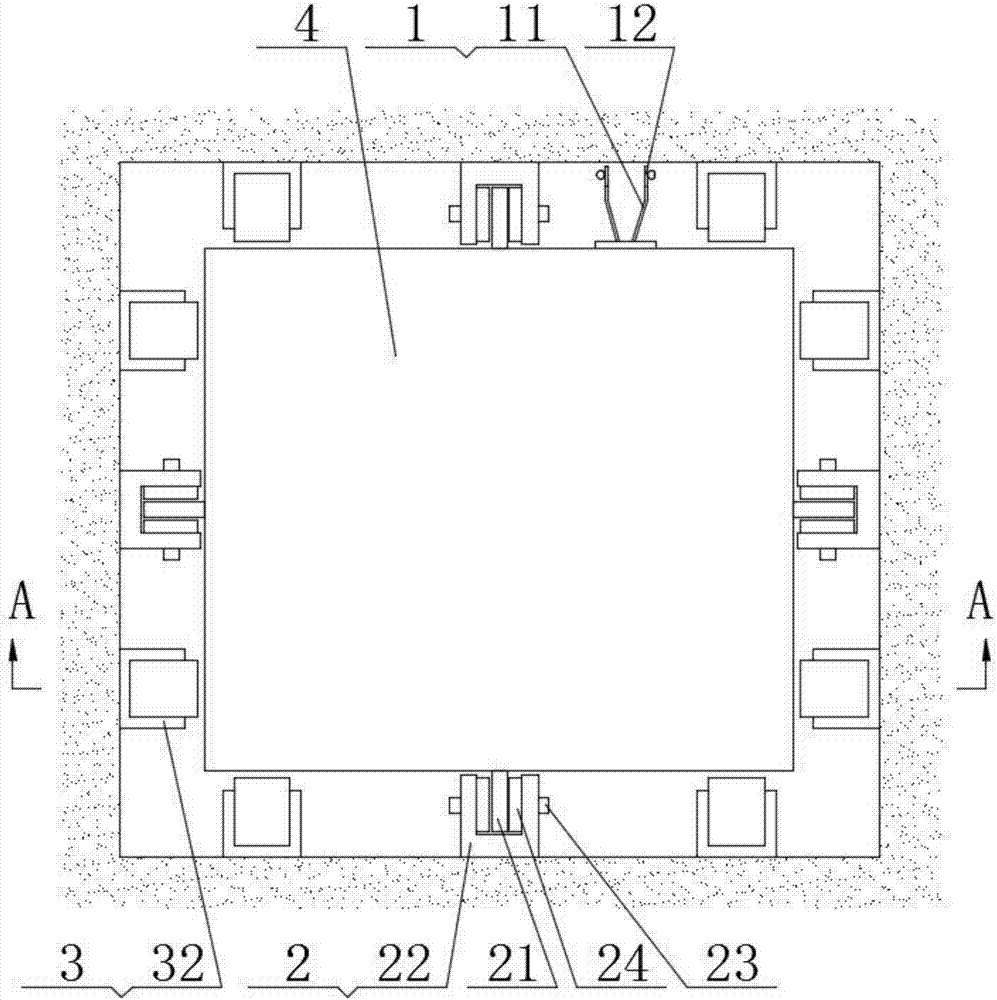

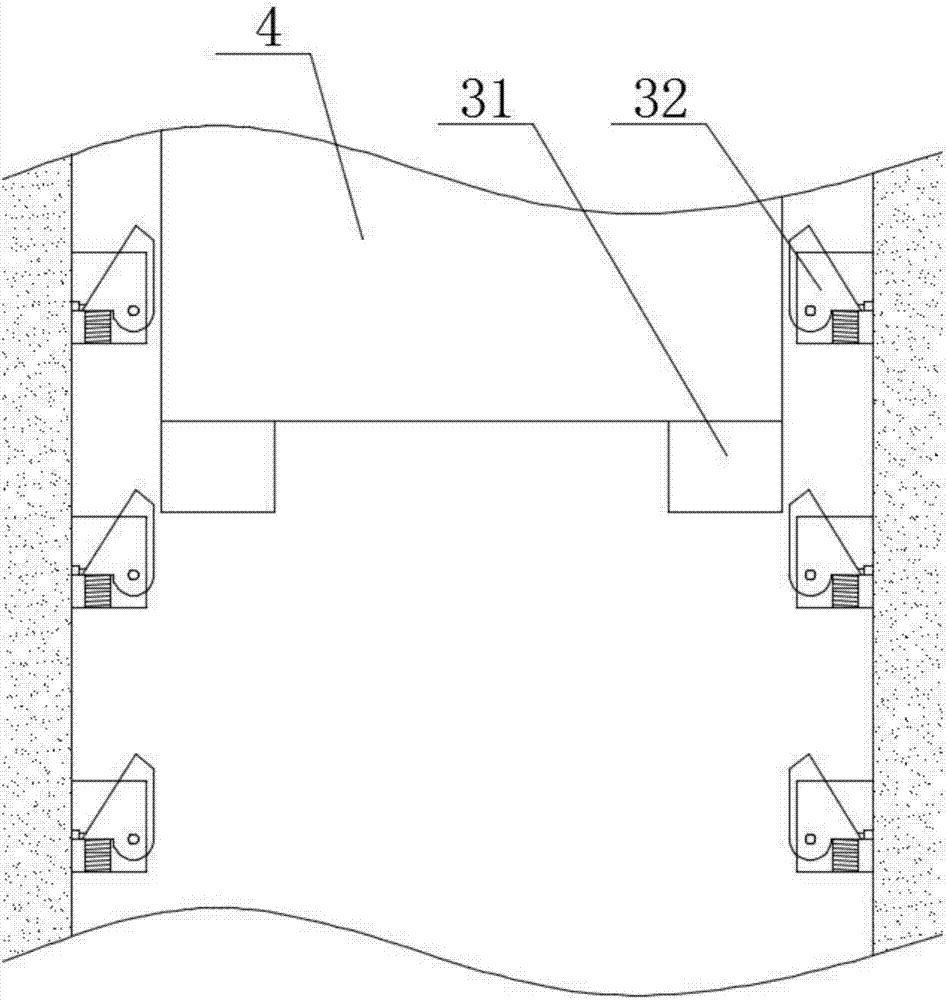

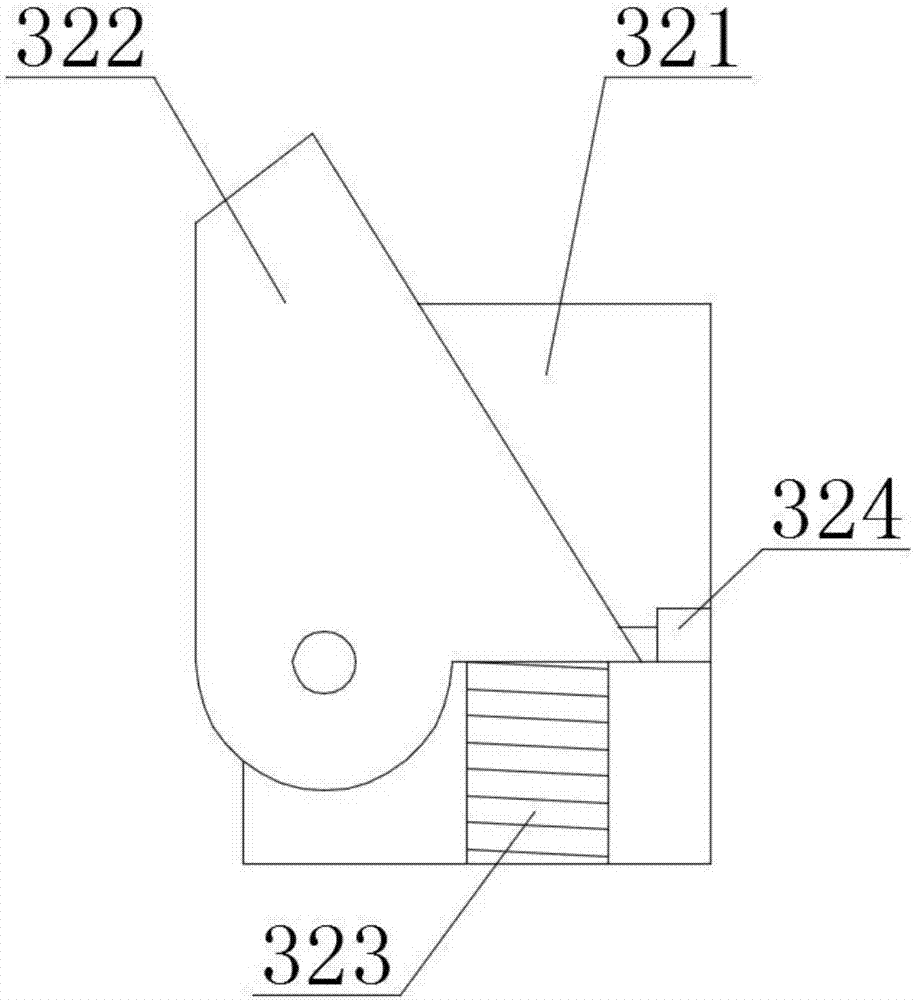

[0034] Such as figure 1 , figure 2 As shown, the elevator lifting safety protection system includes a power taking device 1, an overspeed protection device 2, an intercepting device 3 and an electric control device.

[0035] The power taking device 1 includes a contact wire running through the elevator shaft and a power receiving mechanism 11 installed on the outer wall of the car 4, the contact wire is connected to the mains, and the top of the power receiving mechanism 11 is equipped with a power receiving slide 12, a bottom The end is connected with the outer wall of the car 4 through a wire pressing mechanism, which can make the power receiving slide 12 of the power receiving mechanism 11 lean against the contact line all the time.

[0036] The overspeed protection device 2 includes a guide rail 21, a guide shoe 22 and a speed monitoring sensor; the guide rail 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com