Automatic pin penetrating device for lifting hooks of gantry crane

A technology for gantry cranes and automatic pinning, which is applied in the directions of transportation, packaging, and load hanging components, etc. It can solve the problems of personal safety threats to climbing workers, cumbersome pinning operations, time-consuming and laborious operations, and unfavorable flood control work, so as to avoid climbing Easy to operate, easy to install, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

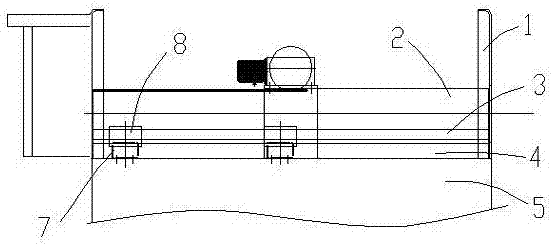

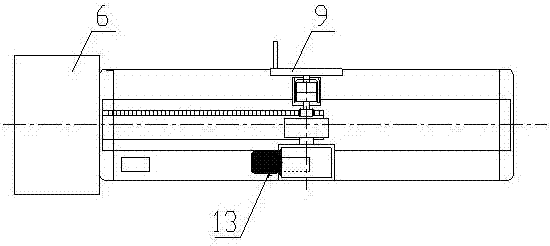

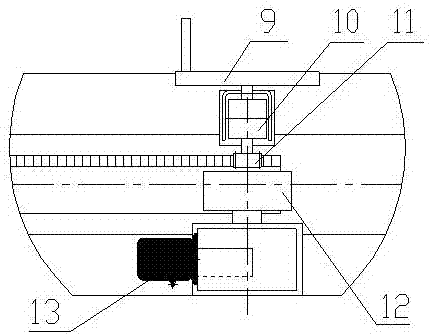

[0028] In this embodiment, an automatic pin-pinning device for the hook of a gantry crane is arranged on the balance beam 17 at the top of the spillway door 18, and includes a pin-pinning bed base 5, an electric control box 6 located at one end of the pin-pinning bed base 5, and The centering seat 14 that the door machine hook 16 cooperates in the up and down direction, such as figure 2 , Figure 4 , Figure 5 As shown, the pin-through bed base 5 is provided with two places, that is, two pin-through devices are established on a balance beam 17, and the two pin-through devices are distributed on the two ends of the balance beam 17, and each pin-through bed base 5 The outer end is equipped with a centering seat 14. The two pin-threading devices can be controlled independently or act simultaneously. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com