FeS2-RGO composite material, preparation method and application

A composite material and hydrothermal reaction technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of high reaction cost, and achieve the effect of good hydrogen evolution effect, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

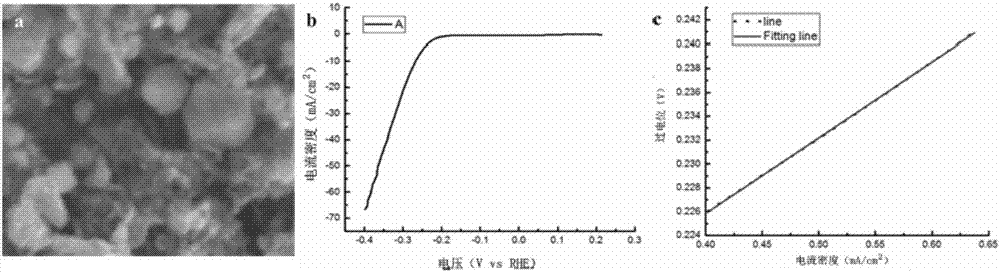

Embodiment 1

[0027] The raw material composition when preparing composite material is as follows:

[0029] Ferric Nitrate Nonahydrate 72mg

[0030] Thioacetamide 145mg

[0031] N,N-Dimethylformamide 16ml

[0032] 5wt% Nation solution 8μL

[0033] 98% concentrated sulfuric acid 13ml

[0034] A little ethanol

[0035] A little anhydrous methanol

[0036] The balance is distilled water

[0037] Above-mentioned composite material is by the preparation method of following steps:

[0038] Graphene oxide was synthesized by a modified Hummer method. Make ferric nitrate nonahydrate into a 0.2M solution, and thioacetamide into a 1M solution, then ultrasonically dissolve graphene oxide in 8ml of DMF, add ferric nitrate and thioacetamide solution, and stir at 90°C 24h, then cooled, centrifuged, and washed 3 times with distilled water to remove unreacted raw materials. Then add the DMF solution and heat it in a hydrothermal kettle for 5-10 hours, then centrifuge, w...

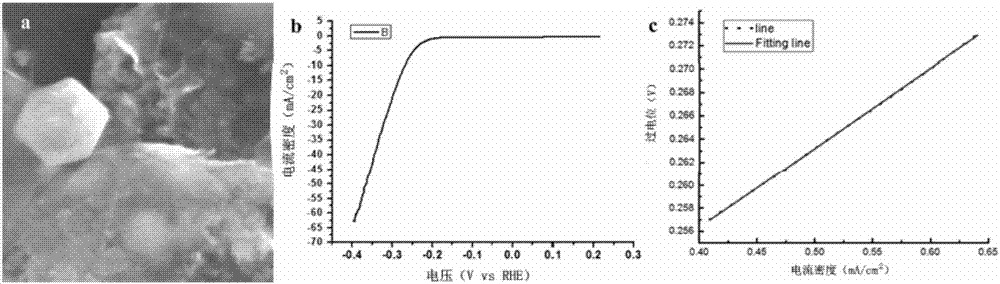

Embodiment 2

[0044] The raw material composition when preparing composite material is as follows:

[0046] Ferric Nitrate Nonahydrate 72mg

[0047] Thioacetamide 150mg

[0048] N,N-Dimethylformamide 16ml

[0049] 5wt% Nation solution 8μL

[0050] 98% concentrated sulfuric acid 13ml

[0051] A little ethanol

[0052] A little anhydrous methanol

[0053] The balance is distilled water

[0054] Above-mentioned composite material is by the preparation method of following steps:

[0055] Graphene oxide was synthesized by a modified Hummer method. Make ferric nitrate nonahydrate into a 0.2M solution, and thioacetamide into a 1M solution, then ultrasonically dissolve graphene oxide in 10ml of DMF, add ferric nitrate and thioacetamide solution, and stir at 90°C 24h, then cooled, centrifuged, and washed 3 times with distilled water to remove unreacted raw materials. Then add the DMF solution and heat it in a hydrothermal kettle for 5-10 hours, then centrifuge, ...

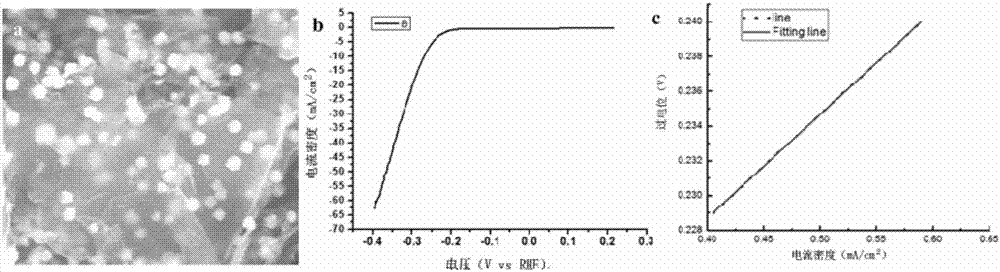

Embodiment 3

[0061] The raw material composition when preparing composite material is as follows:

[0062] Graphene Oxide 4mg

[0063] Ferric Nitrate Nonahydrate 80mg

[0064] Thioacetamide 150mg

[0065] N,N-Dimethylformamide 16ml

[0066] 5wt% Nation solution 10μL

[0067] 98% concentrated sulfuric acid 13ml

[0068] A little ethanol

[0069] A little anhydrous methanol

[0070] The balance is distilled water

[0071] Above-mentioned composite material is by the preparation method of following steps:

[0072] Graphene oxide was synthesized by a modified Hummer method. Make ferric nitrate nonahydrate into a 0.2M solution, and thioacetamide into a 1M solution, then ultrasonically dissolve graphene oxide in 10ml of DMF, add ferric nitrate and thioacetamide solution, and stir at 90°C 24h, then cooled, centrifuged, and washed 3 times with distilled water to remove unreacted raw materials. Then add the DMF solution and heat it in a hydrothermal kettle for 5-10 hours, then centrifuge,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com