Detection method for de-binding of metal matrix composite

A composite material and detection method technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of inability to achieve detection effect, difficult ultrasonic guided wave mode, low resolution, etc., and achieves flexible use and fast detection speed. , the effect of high recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: a kind of metal matrix composite material debonding detection method mainly comprises the following steps:

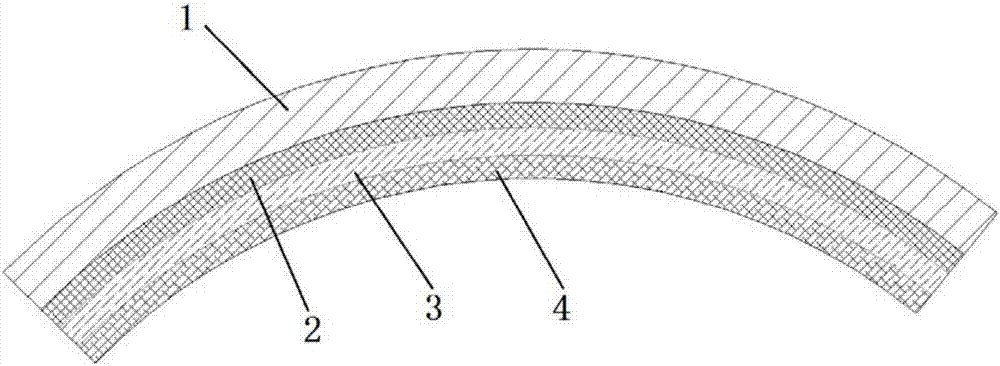

[0038] Step 1: placing the electromagnetic ultrasonic body wave transducer on the surface of the metal matrix 1 of the metal matrix composite;

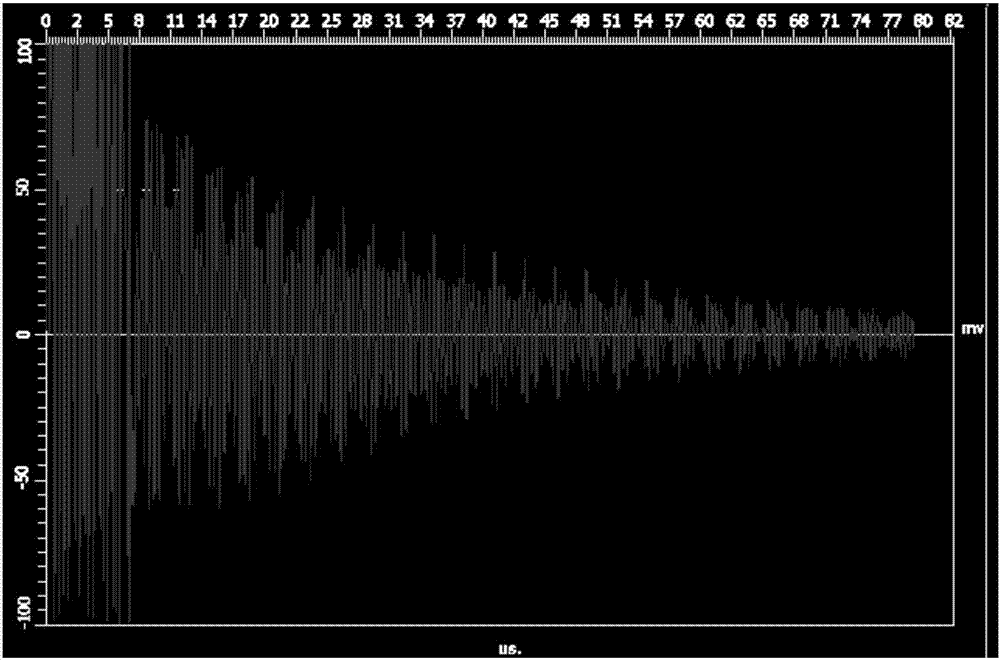

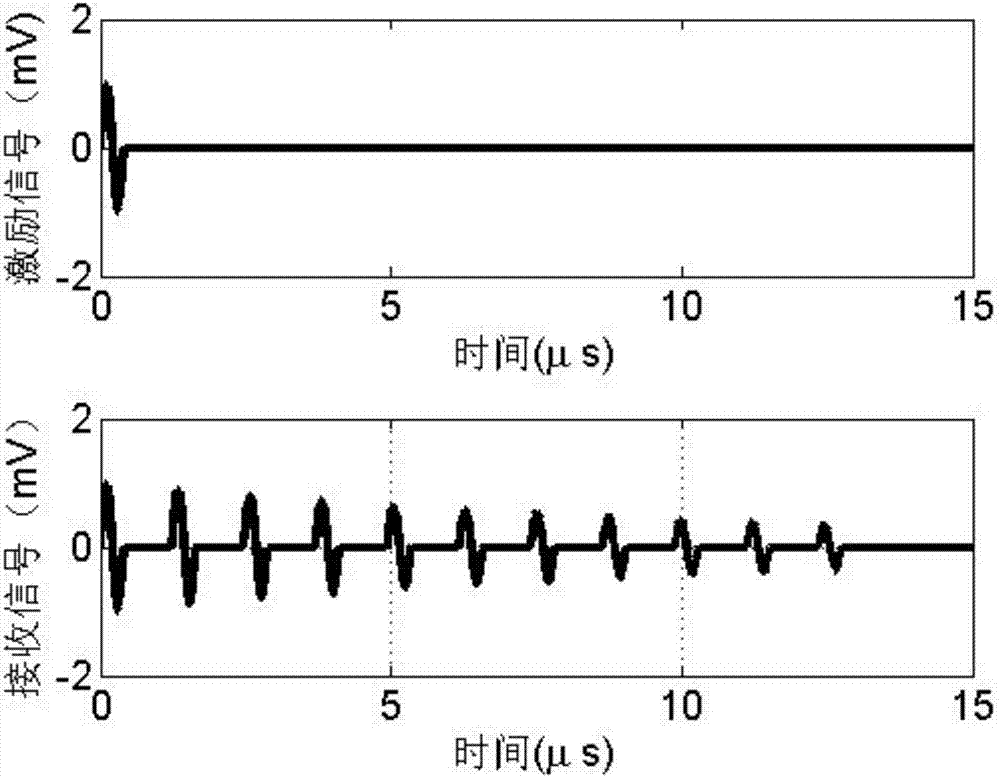

[0039] Step 2: According to the thickness of the metal matrix 1 in the metal matrix composite material, the excitation frequency f of the excitation source is calculated by the following formula (1) and formula (2), and at the same time, the excitation time is set to exceed the time of at least one echo. The source is excited by positive and negative alternating multi-period continuous pulses, which resonates in the thickness direction of the metal composite material;

[0040]

[0041] f=nf 0 Formula (2)

[0042] where f 0 is the resonance fundamental frequency of the metal matrix composite, v is the propagation velocity of the ultrasonic wave along the thickness direction, d is the thickness of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com