Low-smoke, halogen-free, flame-retarding and fireproof polyolefin insulated cable and preparation method thereof

A flame-retardant, fire-resistant and insulated cable technology, which is applied in the direction of insulated cables, cable/conductor manufacturing, insulators, etc., can solve the problems of affecting the flame-retardant temperature and flame-retardant time of cables, producing a large amount of smoke and toxic gases, and single flame-retardant materials. , to achieve safe and reliable flame retardant effect, reduce fire spread speed, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

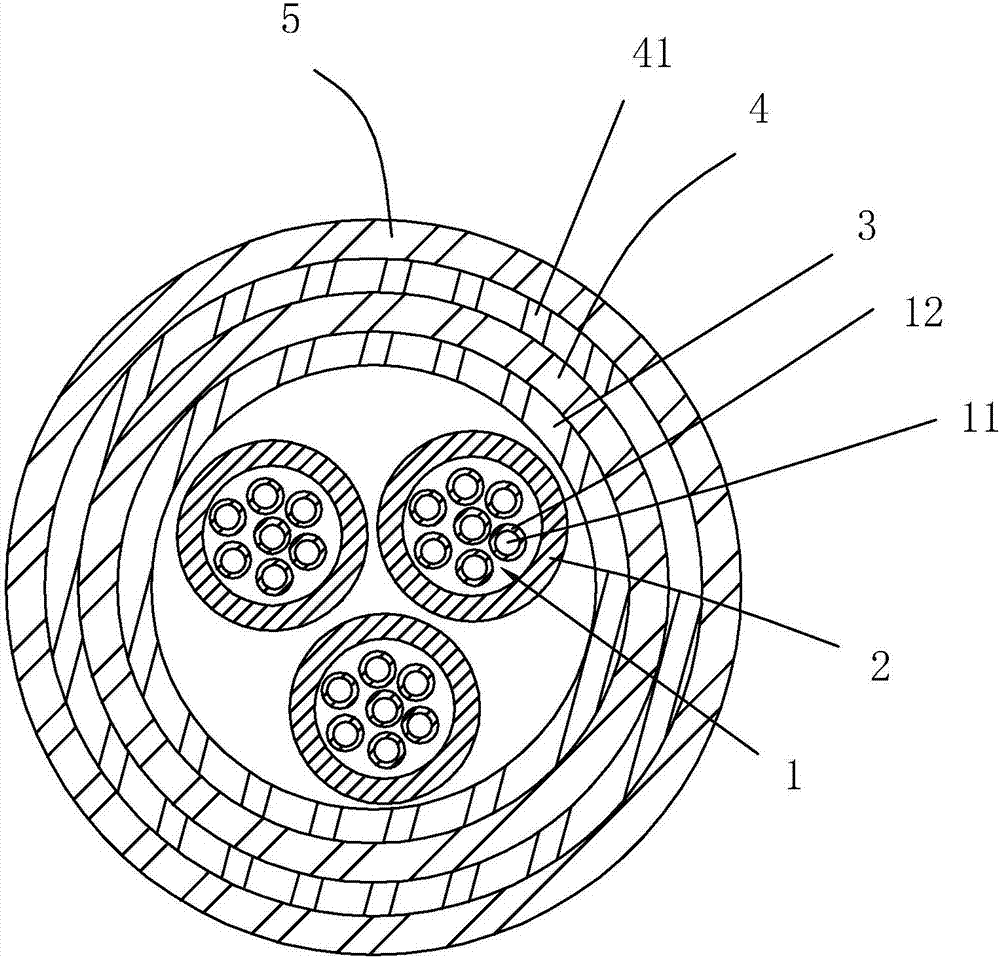

[0043] A low-smoke, halogen-free, flame-retardant, fire-resistant polyolefin insulated cable, such as figure 1 As shown, it includes insulated wire core group 1, refractory layer 2, insulating layer 3, oxygen barrier layer 4 and protective sheath layer 5 from inside to outside; wherein, insulated wire core group 1 has multiple groups, and each insulated wire core is insulated The wire core is formed by twisting a plurality of insulated wire cores, each insulated wire core is composed of a conductor 11 and a high-temperature insulation layer 12 wrapped outside the conductor 11, and the refractory layer 2 is covered outside the high-temperature insulation layer 12;

[0044] The high-temperature insulating layer 12 includes the following components in parts by weight, 50 parts of polyethylene resin and / or polyvinyl chloride resin, 5 parts of Kevlar fiber, and 5 parts of montmorillonite;

[0045] The refractory layer 2 includes the following components in parts by weight: 5 parts ...

Embodiment 2

[0050] A low-smoke, halogen-free, flame-retardant and refractory polyolefin insulated cable, the high-temperature insulating layer 12 includes the following components in parts by weight: 55 parts of polyethylene resin and / or polyvinyl chloride resin, 7 parts of Kevlar fiber, and 7 parts of silicon micropowder;

[0051] The refractory layer 2 includes the following components in parts by weight: 7 parts of silicon micropowder, 55 parts of polyethylene resin and / or polyvinyl chloride resin, 7 parts of glass fiber, 7 parts of polysulfone fiber, and 6 parts of melamine amide inorganic montmorillonite , 15 parts of polyorganosiloxane, 1.5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 1.5 parts of microcapsule pigment;

[0052] The insulating layer 3 includes the following components in parts by weight: 55 parts of polyethylene resin and / or polyvinyl chloride resin, 7 parts of Kevlar fiber, and 7 parts of silicon micropowder;

[0053] The oxygen barrier layer ...

Embodiment 3

[0056] A low-smoke, halogen-free, flame-retardant and refractory polyolefin insulated cable, the warm insulating layer 3 includes the following components in parts by weight: 60 parts of polyethylene resin and / or polyvinyl chloride resin, 10 parts of Kevlar fiber, and 10 parts of mica powder;

[0057] The refractory layer 2 includes the following components in parts by weight: 10 parts of mica powder, 60 parts of polyethylene resin and / or polyvinyl chloride resin, 10 parts of glass fiber, 10 parts of polysulfone fiber, 7 parts of melamine amide inorganic montmorillonite , 20 parts of polyorganosiloxane, 3 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 3 parts of microcapsule pigment; insulating layer 3 comprises the following components by weight: polyethylene resin and / or polyvinyl chloride 60 parts of resin, 10 parts of Kevlar fiber, 10 parts of mica powder;

[0058] The oxygen barrier layer 4 includes the following components in parts by weight: 60 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com