Coal anaerobic mining method

A mining method and coal mining technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of inability to continue to develop deep resources and high production costs, and achieve the effect of reducing the risk of gas explosion, improving economy, and safe recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

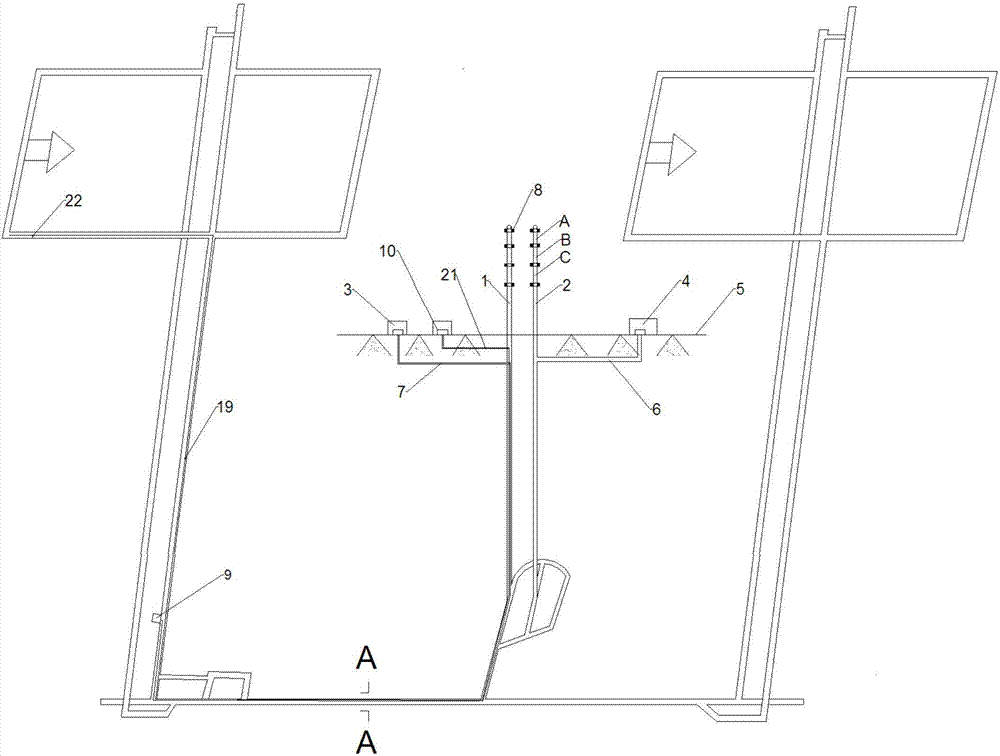

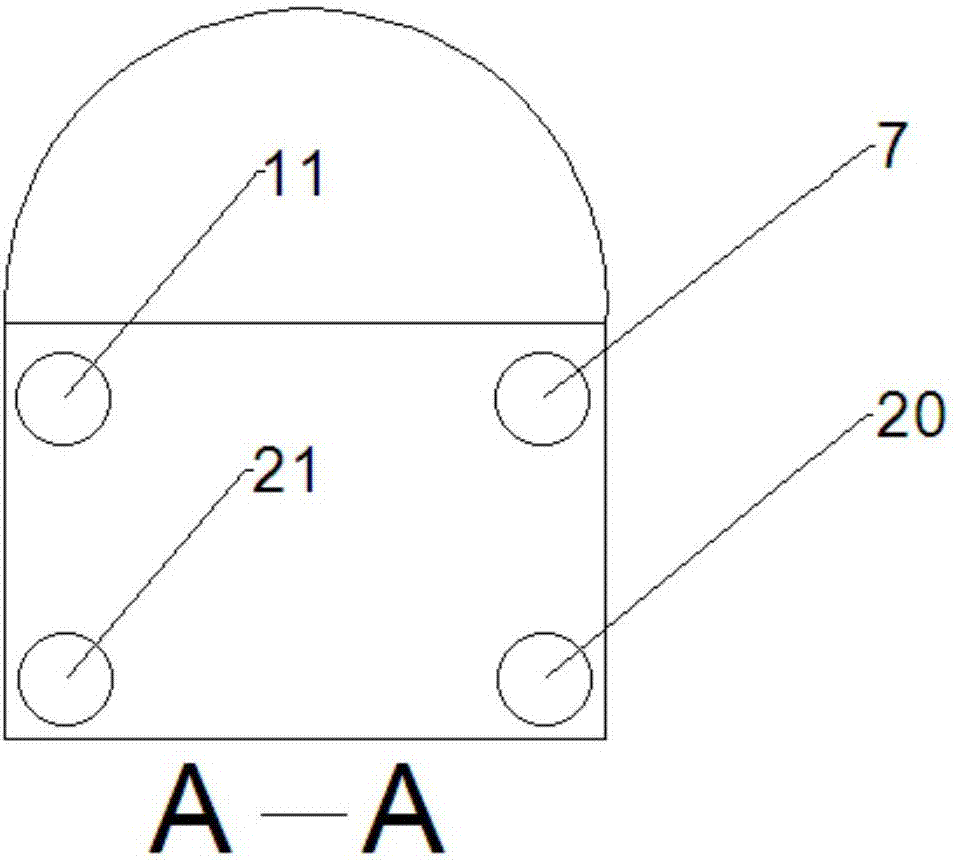

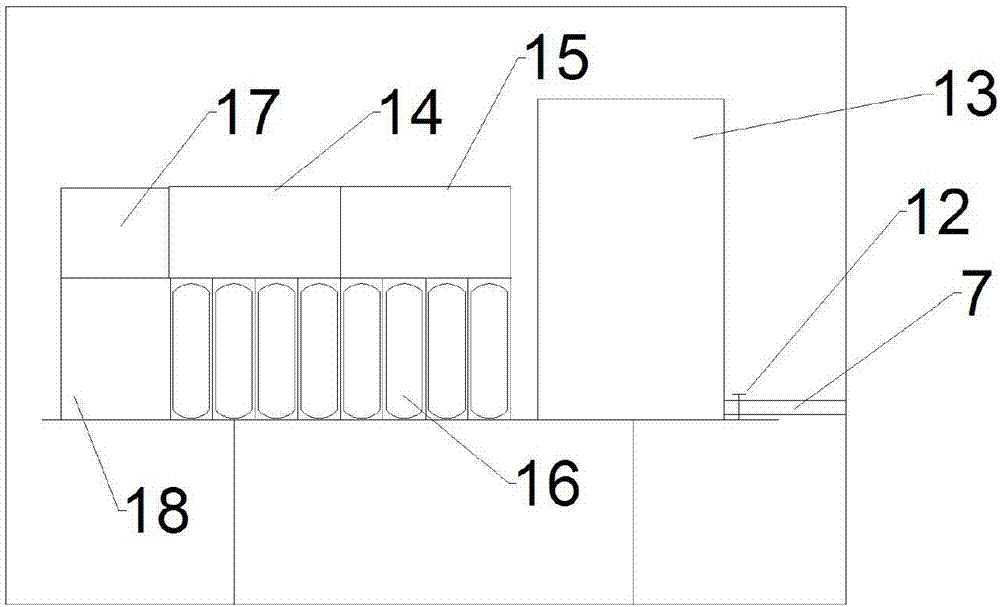

[0043] A kind of coal anaerobic mining method, the schematic diagram of mine layout state in the process of coal anaerobic mining is as follows figure 1 shown, figure 1 The cross-sectional view of A-A in the figure 2 As shown, the schematic diagram of the fixed air supply chamber is shown in Fig. image 3 shown, including the following steps:

[0044] Step 1, Mine Seal:

[0045] Four sealing doors 8 are set at the entrances of the main shaft 1 and the auxiliary shaft 2 respectively. The distance between the sealing doors 8 is 15m. The four sealing doors of the main shaft 1 and the auxiliary shaft 2 form 3 cabins, respectively It is the first cabin, the second cabin and the third cabin, the first cabin is the aerobic cabin A, the second cabin is the transition cabin B, and the third cabin is the anaerobic cabin C, so that the mine is closed to a sealed state to ensure the atmosphere inside the mine. The environment is isolated from the ground atmosphere;

[0046] Step 2, co...

Embodiment 2

[0053] A kind of coal anaerobic mining method, the schematic diagram of mine layout state in the process of coal anaerobic mining is as follows figure 1 shown, figure 1 The cross-sectional view of A-A in the figure 2 As shown, the schematic diagram of the fixed air supply chamber is shown in Fig. image 3 shown, including the following steps:

[0054] Step 1, Mine Seal:

[0055] Four sealed doors 8 are set at the entrances of the main shaft 1 and the auxiliary shaft 2 respectively, and the distance between the sealed doors 8 is 25m. The four sealed doors of the main shaft 1 and the auxiliary shaft 2 form three cabins, respectively It is the first cabin, the second cabin and the third cabin, the first cabin is the aerobic cabin A, the second cabin is the transition cabin B, and the third cabin is the anaerobic cabin C, so that the mine is closed to a sealed state to ensure the atmosphere inside the mine. The environment is isolated from the ground atmosphere;

[0056] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com