Brightness enhancement film used for coating quantum dots

A technology of quantum dots and brightness enhancement films, applied in optics, instruments, nonlinear optics, etc., to achieve the effect of overcoming sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

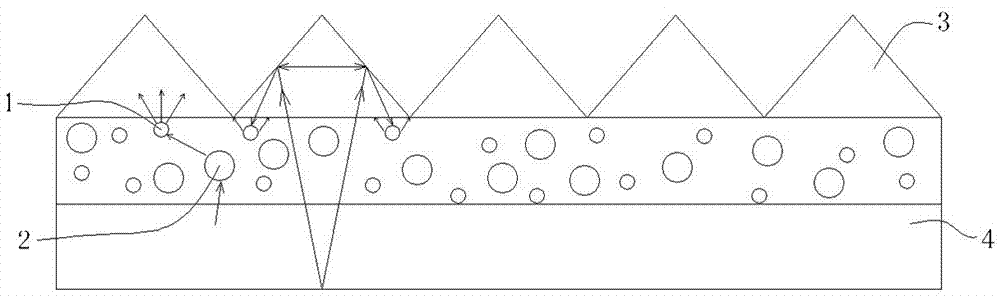

[0034] refer to figure 1 , a brightness-enhancing film coated with quantum dots, including a base film 4, the base film 4 is coated with a two-layer structure: the first layer structure is a thermosetting acrylic resin containing quantum dots 1 and diffusion particles 2, with To protect the stability of quantum dots by blocking water; the second layer structure is UV epoxy resin 3 on the first layer structure which is cured by UV into a prism structure, which is used to block oxygen to protect the stability of quantum dots;

[0035] The first layer structure of the brightness enhancing film is composed of the following components:

[0036] Quantum dots: 0.5 parts by mass;

[0037] Diffused particles: 7 parts by mass;

[0038] Acrylic resin: 60 parts by mass;

[0039] Curing agent: 5 parts by mass;

[0040] Antistatic agent: 0.6 parts by mass;

[0041] Leveling agent: 1 part by mass;

[0042] Organic solvent: 50 parts by mass;

[0043] The second layer structure of the b...

Embodiment 2

[0058] The first layer structure of the brightness enhancing film is composed of the following components:

[0059] Quantum dots: 0.1 parts by mass;

[0060] Diffused particles: 8 parts by mass;

[0061] Acrylic resin: 55 parts by mass;

[0062] Curing agent: 7 parts by mass;

[0063] Antistatic agent: 1.5 parts by mass;

[0064] Leveling agent: 1.2 parts by mass;

[0065] Organic solvent: 70 parts by mass;

[0066] The second layer structure of the brightness enhancing film consists of the following components:

[0067] Photoinitiator: 1 part by mass;

[0068] Monomer: 55 parts by mass;

[0069] Epoxy resin: 32 parts by mass.

[0070] The remaining implementation modes are the same as the first embodiment.

Embodiment 3

[0072] The first layer structure of the brightness enhancing film is composed of the following components:

[0073] Quantum dots: 1 part by mass;

[0074] Diffused particles: 6 parts by mass;

[0075]Acrylic resin: 65 parts by mass;

[0076] Curing agent: 3 parts by mass;

[0077] Antistatic agent: 0.1 parts by mass;

[0078] Leveling agent: 0.5 parts by mass;

[0079] Organic solvent: 45 parts by mass;

[0080] The second layer structure of the brightness enhancing film consists of the following components:

[0081] Photoinitiator: 4 parts by mass;

[0082] Monomer: 50 parts by mass;

[0083] Epoxy resin: 30 parts by mass.

[0084] The remaining implementation modes are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com