Preparation method of gram-level nitrogen-doped graphene quantum dot capable of being used as fluorescent ink

A graphene quantum dot and fluorescent ink technology is applied in the preparation of nitrogen-doped graphene quantum dots, and in the field of preparation of gram-level nitrogen-doped graphene quantum dots, achieving low market price, short preparation time and high fluorescence yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

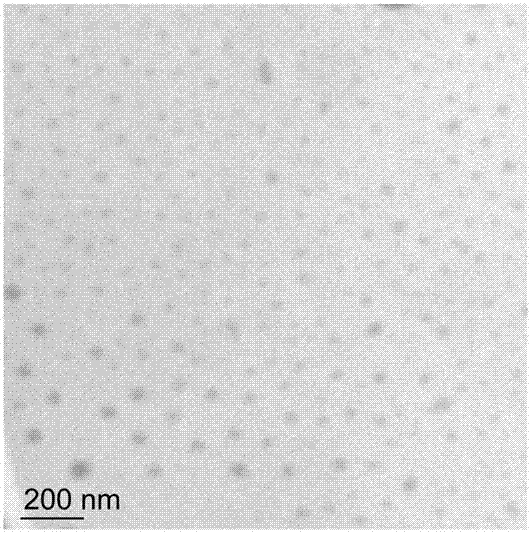

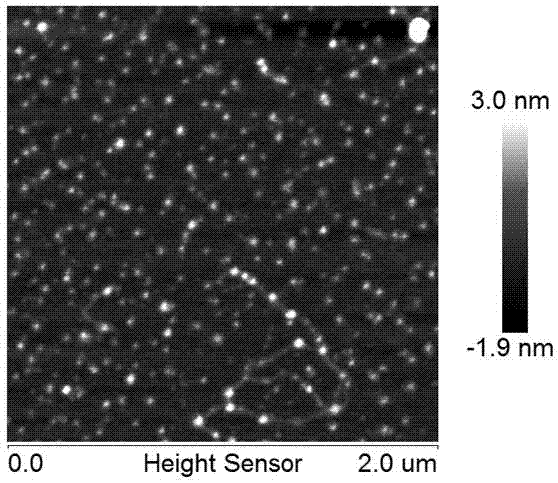

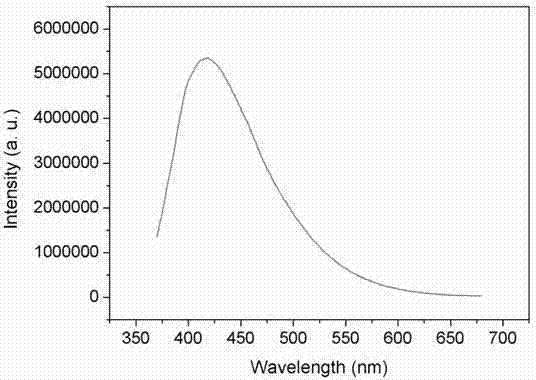

[0018] Example 1: Weigh 3 g of nitrilotriacetic acid and put it into the reaction kettle, and pour nitrogen into the reaction kettle at a flow rate of 2 mL / s for 5 minutes, then seal the reaction kettle and react at 230° C. for 3 hours. The product was dissolved in ethanol, and the supernatant was taken after centrifugation at a speed of 10,000 rpm, which was a saturated ethanol solution of nitrogen-doped graphene quantum dots. One volume of the saturated ethanol solution and one volume of glycerin are mixed, and the oily mixed liquid is poured into the washed ballpoint pen core to obtain an oily fluorescent ink for a ballpoint pen. The ethanol solution is evaporated to dryness, dissolved in water to obtain a saturated aqueous solution, and sucked into a fountain pen ink bag to obtain a water-like fluorescent ink for a fountain pen. Due to the low reaction time of the product, the polymerization reaction is not complete, so the yield is low, but it does not affect the applicati...

Embodiment 2

[0019] Example 2: Weigh 3 g of nitrilotriacetic acid and put it into the reactor, and pour nitrogen into the reactor at a flow rate of 5 mL / s for 10 minutes, then seal the reactor and react at 230° C. for 3 hours. The product was dissolved in ethanol, and the supernatant was taken after centrifugation at a speed of 10,000 rpm, which was a saturated ethanol solution of nitrogen-doped graphene quantum dots. One volume of the saturated ethanol solution and one volume of glycerin are mixed, and the oily mixed liquid is poured into the washed ballpoint pen core to obtain an oily fluorescent ink for a ballpoint pen. The ethanol solution is evaporated to dryness, dissolved in water to obtain a saturated aqueous solution, and sucked into a fountain pen ink bag to obtain a water-like fluorescent ink for a fountain pen. In this example, the flow rate and time of nitrogen gas flow are changed, but there is no obvious difference in the properties and yield of the product. It can be seen th...

Embodiment 3

[0020] Example 3: Weigh 5 g of nitrilotriacetic acid and put it into the reaction kettle, and pour nitrogen into the reaction kettle at a flow rate of 2 mL / s for 5 minutes, then seal the reaction kettle and react at 250° C. for 3 hours. The product was dissolved in ethanol, and the supernatant was taken after centrifugation at a speed of 10,000 rpm, which was a saturated ethanol solution of nitrogen-doped graphene quantum dots. One volume of the saturated ethanol solution and one volume of glycerin are mixed, and the oily mixed liquid is poured into the washed ballpoint pen core to obtain an oily fluorescent ink for a ballpoint pen. The ethanol solution is evaporated to dryness, dissolved in water to obtain a saturated aqueous solution, and sucked into a fountain pen ink bag to obtain a water-like fluorescent ink for a fountain pen. In this embodiment, the reaction temperature is increased, and the polymerization is performed at a sufficiently high temperature, so that the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com