Method for improving fluorescence yield and stability of bi-based perovskite nano material and product

A technology of nanomaterials and fluorescence yield, applied in chemical instruments and methods, luminescent materials, organic chemistry, etc., can solve the problems of QLED devices being far apart, poor fluorescence performance of nanomaterials, large defect density, etc., to achieve improved fluorescence quantum Improved yield and stability, fluorescence quantum yield and stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the method for improving the fluorescence yield and stability of bismuth-based perovskite nanomaterials, the specific preparation steps are as follows:

[0026] Step 1: Clean the white glass bottle with acetone, isopropanol, and deionized water for 15 minutes, then dry it with a nitrogen gun;

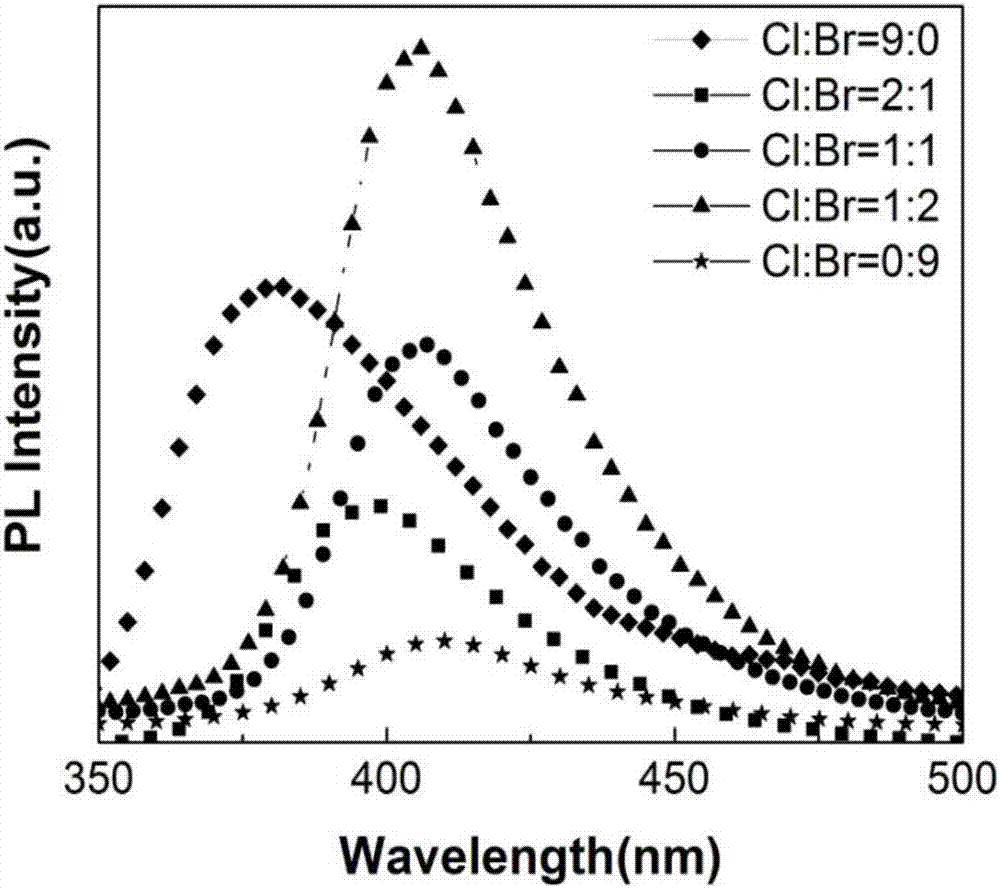

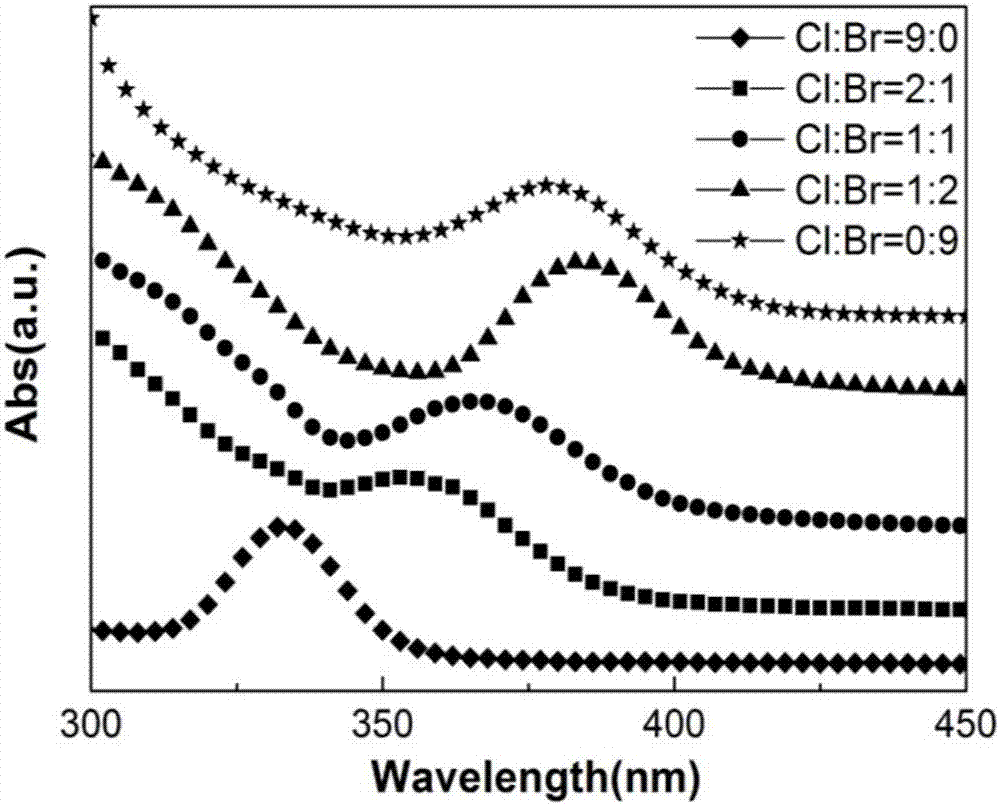

[0027] Step 2: Pour 0.0418g octylamine bromide (OlaBr) into glass bottle A, then add 1mL DMF to obtain solution A, then weigh 0.0315g bismuth chloride (BiCl 3 ) and 0.0448g bismuth bromide (BiBr 3 ) into glass bottle B, adding 2 mL of ethyl acetate to bottle B to dissolve the reactant to obtain solution B, and then mixing the two solutions to obtain precursor solution C;

[0028] Step 3: Add 5mL of n-octane and 0.3mL of oleic acid into glass bottle B as anti-solvent, and heat it to 50°C;

[0029] Step 4: Inject 1mL of the precursor solution into the anti-solvent quickly, stir the reaction for one minute, then immerse the glass bottle in cold water to cool qu...

Embodiment 2

[0032] In this embodiment, the method for improving the fluorescence yield and stability of bismuth-based perovskite nanomaterials, the specific preparation steps are as follows:

[0033] Step 1: Clean the white glass bottle with acetone, isopropanol, and deionized water for 15 minutes, then dry it with a nitrogen gun;

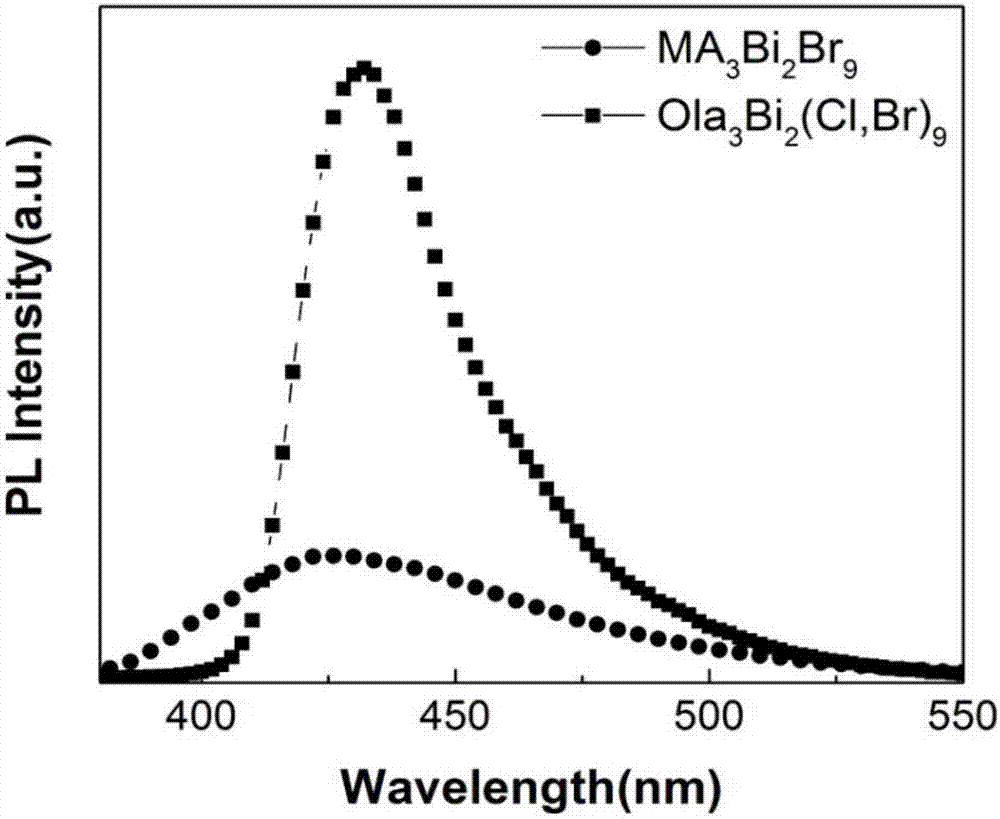

[0034] Step 2: Pour 0.0224g methylamine bromide (MABr) into glass bottle A, then add 1mL DMF to obtain solution A, then weigh 0.021g bismuth chloride (BiCl 3 ) and 0.031g bismuth bromide (BiBr 3 ) was poured into glass bottle B, and 1 mL of ethyl acetate was added to bottle B to dissolve the reactant to obtain solution B, and then the two solutions were mixed to obtain precursor solution C;

[0035] Step 3: Add 2.5mL of n-octane and 0.15mL of oleic acid into glass bottle B as anti-solvent, and heat it to 50°C;

[0036] Step 4: Inject 1mL of the precursor solution into the anti-solvent quickly, stir the reaction for one minute, then immerse the glass bottle i...

Embodiment 3

[0039] In this embodiment, the method for improving the fluorescence yield and stability of bismuth-based perovskite nanomaterials, the specific preparation steps are as follows:

[0040] Step 1: Clean the white glass bottle with acetone, isopropanol, and deionized water for 15 minutes, then dry it with a nitrogen gun;

[0041] Step 2: Pour 0.0224g methylamine bromide (MABr) and 0.0418g octylamine bromide (OlaBr) into glass bottle A, then add 2mL DMF to obtain solution A, then weigh 0.0596g bismuth chloride (BiCl 3 ) and 0.0419g bismuth bromide (BiBr 3 ) into glass bottle B, adding 2 mL of ethyl acetate to bottle B to dissolve the reactant to obtain solution B, and then mixing the two solutions to obtain precursor solution C;

[0042] Step 3: Add 5mL of n-octane and 0.3mL of oleic acid into glass bottle B as anti-solvent, and heat it to 50°C;

[0043] Step 4: Inject 1mL of the precursor solution into the anti-solvent quickly, stir the reaction for one minute, then immerse th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com