Method for ultrasonically and electrochemically synthesizing water-soluble CdTe quantum dot

A technology of sonoelectrochemistry and quantum dots, applied in chemical instruments and methods, electrolytic processes, electrolytic components, etc., can solve problems such as harsh reaction conditions and complex reaction processes, and achieve the effect of simple and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for sonoelectrochemically synthesizing water-soluble CdTe quantum dots, the steps are as follows:

[0040] (1) Stir and add CdCl with a concentration of 50mM into 47mL pure water in sequence 2 2 ml, 17.6 μL of 3-mercaptopropionic acid, 50 mM Na 2 TeO 3 1mL, so that the molar ratio of the three is 2:4:1;

[0041] (2) Adjust the above mixed solution with NaOH to make the pH 11;

[0042] (3) Place the sonoelectrochemical device containing the ultrasonic electrode in the solution adjusted in step (2), and set the reaction parameters of the sonoelectrochemical device, which are current size 0.01A, current pulse time 0.5s, current intermittent time 1.5s, ultrasonic time 0.3s, reaction temperature 70°C, reaction time 3000s, ultrasonic pulse intensity 20W.

[0043] (4) Start the sonoelectrochemical device, the reaction begins, and CdTe quantum dots are finally formed.

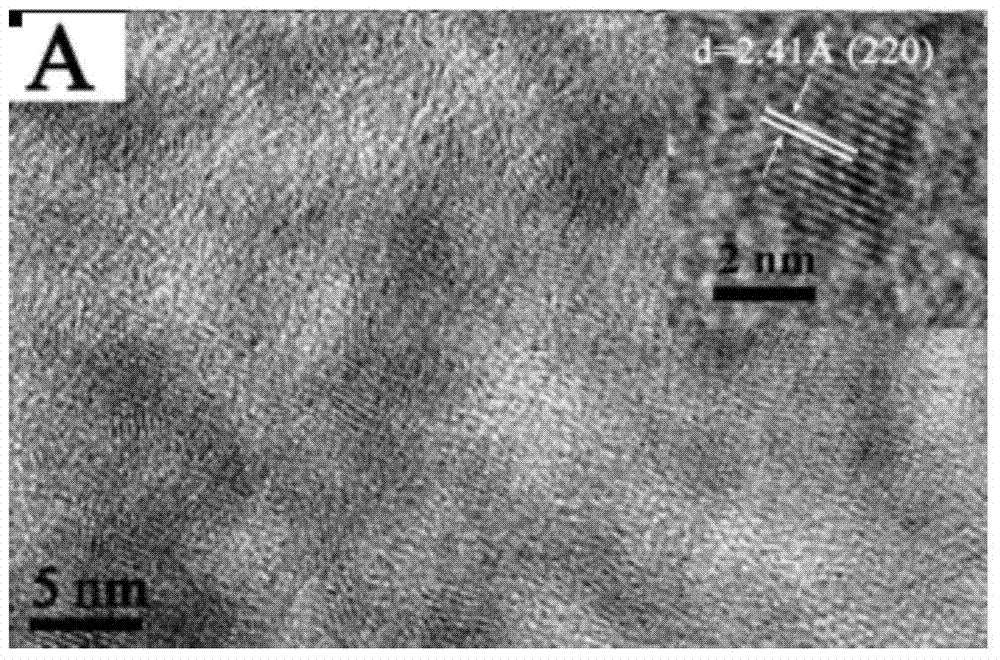

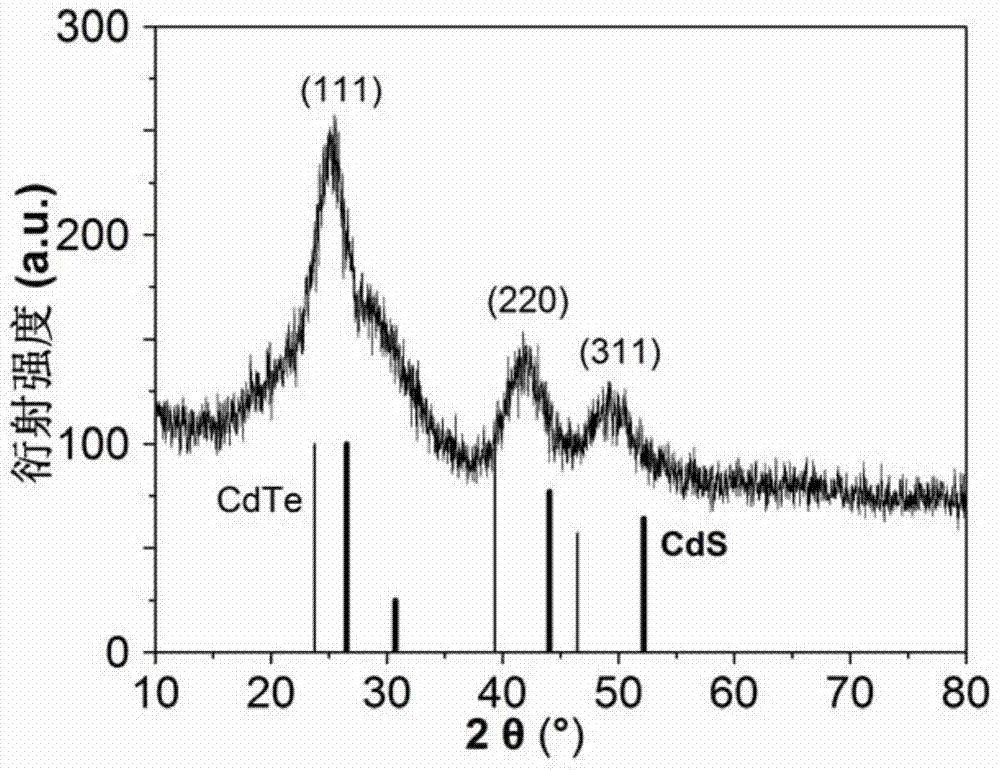

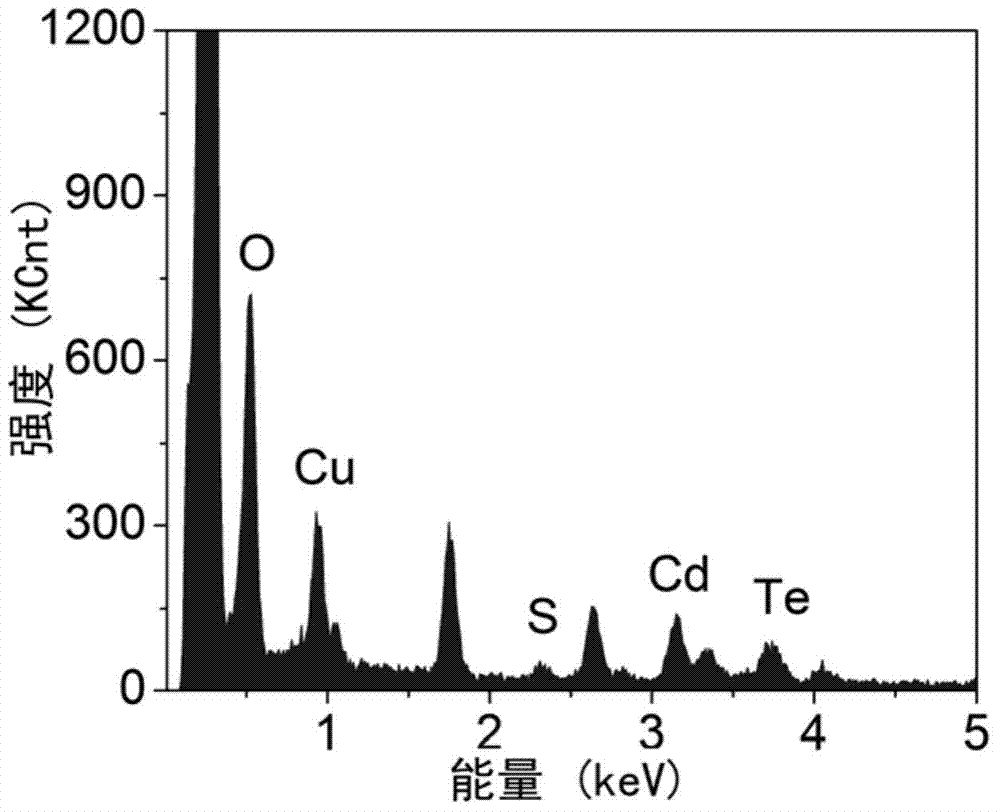

[0044] like figure 1 As mentioned, under the conditions of this embodiment, it can be seen thr...

Embodiment 2

[0049] A method for sonoelectrochemically synthesizing water-soluble CdTe quantum dots, the steps are as follows:

[0050] (1) Stir and add CdCl with a concentration of 50mM into 235mL pure water in sequence 2 10ml, 88μL of 3-mercaptopropionic acid with a concentration of 50mM Na 2 TeO 3 5mL, so that the molar ratio of the three is 2:4:1;

[0051] (2) Adjust the above mixed solution with NaOH so that the pH is 10;

[0052] (3) Place the sonoelectrochemical device containing the ultrasonic electrode in the solution adjusted in step (2), and set the reaction parameters of the sonoelectrochemical device, which are current size 0.05A, current pulse time 0.1s, current intermittent time 1.9s, ultrasonic time 0.1s, reaction temperature 70°C, reaction time 1000s, ultrasonic pulse intensity 20W.

[0053] (4) Start the sonoelectrochemical device, the reaction begins, and CdTe quantum dots are finally formed.

Embodiment 3

[0055] A method for sonoelectrochemically synthesizing water-soluble CdTe quantum dots, the steps are as follows:

[0056] (1) Stir and add CdCl with a concentration of 50mM into 24mL pure water in sequence 2 1ml, 8.8μL of 3-mercaptopropionic acid with a concentration of 50mM Na 2 TeO 3 1mL, so that the molar ratio of the three is 2:4:1;

[0057] (2) Adjust the above mixed solution with NaOH to make the pH 11

[0058] (3) Place the sonoelectrochemical device containing the ultrasonic electrode in the solution adjusted in step (2), and set the reaction parameters of the sonoelectrochemical device, which are current size 0.1A, current pulse time 1.0s, current intermittent time 1.0s, ultrasonic time 0.1s, reaction temperature 70°C, reaction time 3000s, ultrasonic pulse intensity 20W.

[0059] (4) Start the sonoelectrochemical device, the reaction begins, and CdTe quantum dots are finally formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com