Backlight module and display device

A backlight module and backlight technology, applied in light guides, optics, optical components, etc., can solve the problems of cost waste, long verification and adjustment cycle, etc., achieve the effect of short adjustment cycle, low cost, and alleviate the polarization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

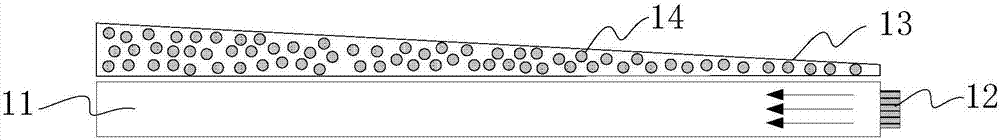

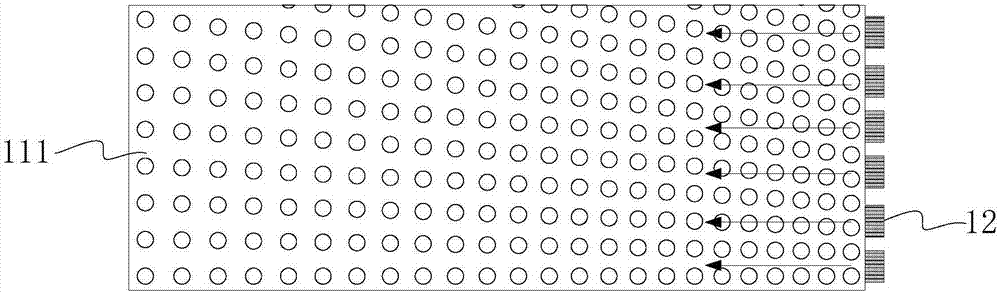

[0049] Implementation Mode 1: Refer to figure 2 , the above-mentioned optical structure is a substrate 151;

[0050] Along the direction away from the backlight 12 , the thickness of the substrate 151 gradually increases.

[0051] In specific implementation, when making the above-mentioned base material 151, the pigment 14 of specific color can be added in the material of making the above-mentioned base material 151, for example, the material of making the above-mentioned base material 151 is preferably a transparent material, for example, polyterephthalic acid can be used Ethylene glycol ester (Polyethylene terephthalate, PET), specifically, a pigment 14 of a specific color can be added during the melting process of the PET particles, and the pigment 14 is evenly distributed in the PET material by stirring, and then the PET material is extruded and stretched into a roll The material is used for the subsequent mass production of the base material 151.

[0052] Setting the t...

Embodiment approach 2

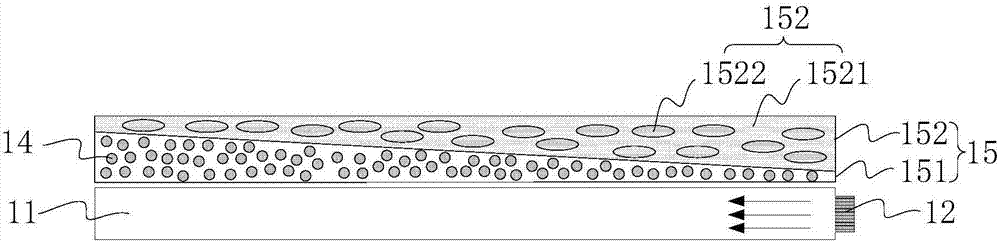

[0053] Implementation mode two: refer to Figure 4 , the above-mentioned optical structure is a diffusion film 152;

[0054] Along the direction away from the backlight 12 , the thickness of the diffusion film 152 increases gradually.

[0055] In practice, when making the above-mentioned diffusion film 152, it is enough to evenly distribute the pigment 14 of a specific color in the material for making the diffusion film 152, and it is relatively easy to realize that the content of the pigment 14 is getting higher and higher along the direction away from the backlight 12. .

[0056] When the above-mentioned optical structure is the diffusion film 152, the thickness of the diffusion film 152 is set to gradually increase along the direction away from the backlight 12, so that the content of the pigment 14 can be more easily realized along the direction away from the backlight 12. The higher it is, the non-white light emitted from the light guide plate 11 can be mixed with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com