Improvements relating to polyurethanes

A polyurethane foam and polyisocyanate technology, applied in the field of polyurethane foam, can solve the problems of narrow processing window and very sensitive to small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

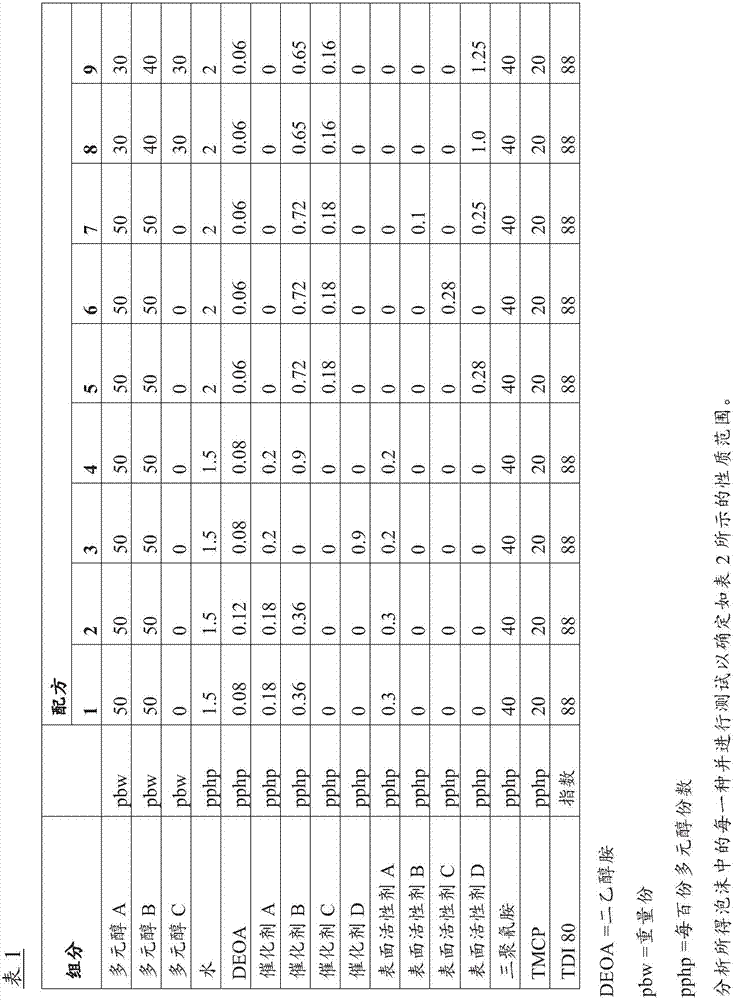

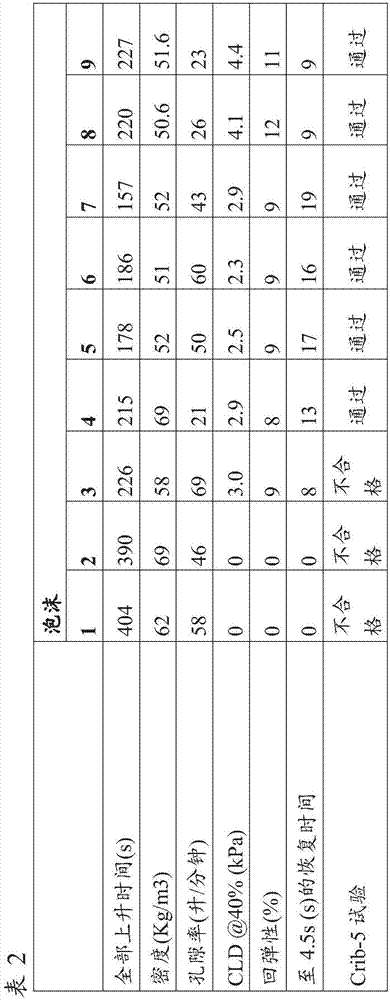

Method used

Image

Examples

preparation example Construction

[0070] Examples of such polymer polyol systems and their preparation are disclosed, for example, in EP-A-076,491, EP-A-343,907 and EP-A-495,551. It is also known that polyurea or polyurethane polymers can be used as dispersion polymers in polymer polyols other than polymers based on ethylenically unsaturated monomers.

[0071] The polymer dispersed in the base polyol may in principle be any such polymer known to be suitable for this purpose. Accordingly, suitable polymers include polymers based on ethylenically unsaturated monomers, especially vinylaromatic hydrocarbons such as styrene, a-methylstyrene, methylstyrene and various other alkyl-substituted styrenes of polymers. Among them, styrene is preferably used. Vinyl aromatic monomers can be used alone or in combination with other ethylenically unsaturated monomers such as acrylonitrile, methacrylonitrile, vinylidene chloride, various acrylates and conjugated dienes such as 1,3-butadiene and combination with isoprene. Ho...

Embodiment 10

[0184] Example 10 (Prophetic)

[0185] Determining an amine catalyst component comprising N,N-dimethylaminoethanol instead of triethylenediamine, wherein N,N-dimethylaminoethanol provides the equivalent of 0.2-0.6 parts per 100 parts by weight of the polyol component ( pphp) gelling activity of triethylenediamine.

[0186] Referring to "Polyurethane Catalysis by Tertiary Amines" (Roger van Maris et al., Journal of Cellular Plastics, Vol. 41 - Jul. 2005, 305), especially Table 1 thereof, it was found that the gelling activity of triethylenediamine was 10.9 (×10), while the gelling activity of N,N-dimethylaminoethanol was 2.91 (×10). On this basis, the amount of N,N-dimethylaminoethanol that provides gelling activity equivalent to 0.2-0.6 parts by weight (pphp) of triethylenediamine per 100 parts by weight of the polyol component is calculated to be 0.75- 2.25 pphp.

[0187] Thus, it is contemplated that a suitable amine catalyst component could consist of 0.75-2.25 pphp dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com