Alloyed hot-dip galvanized steel sheet manufacturing method

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in hot-dip galvanizing process, manufacturing tools, maintenance of heating chamber, etc. The best dew point range and other issues can be achieved to suppress the reduction of tensile strength and reduce the alloying temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

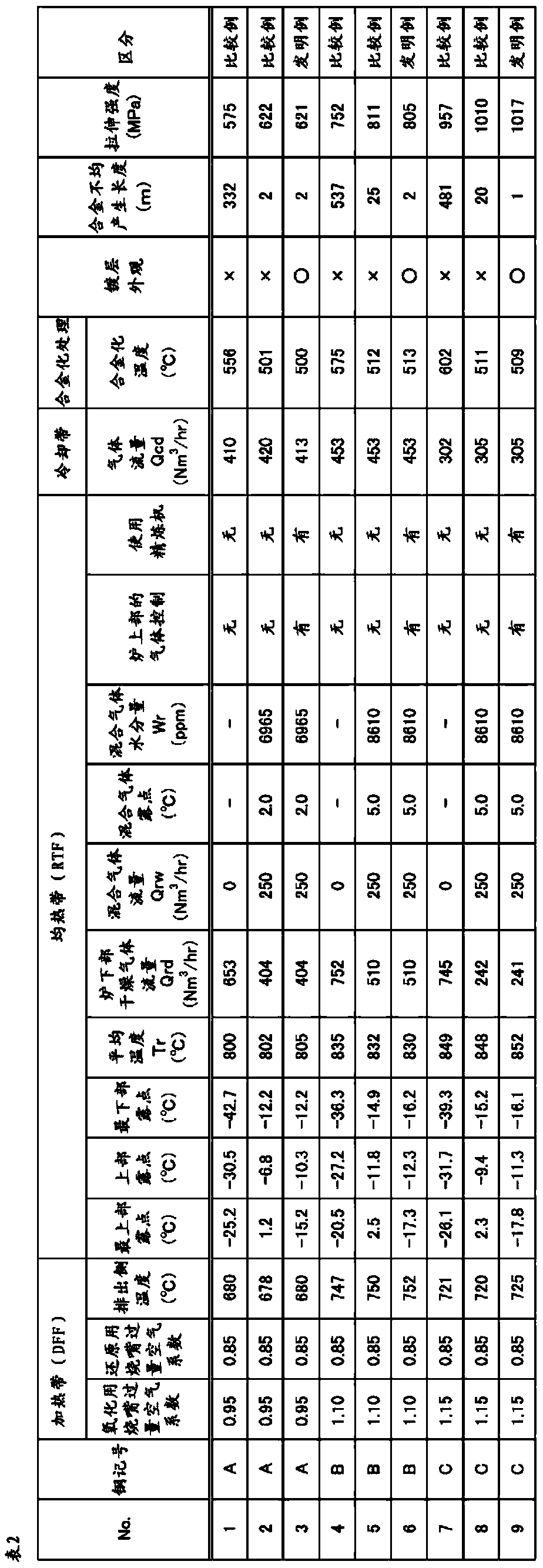

[0076] (experimental conditions)

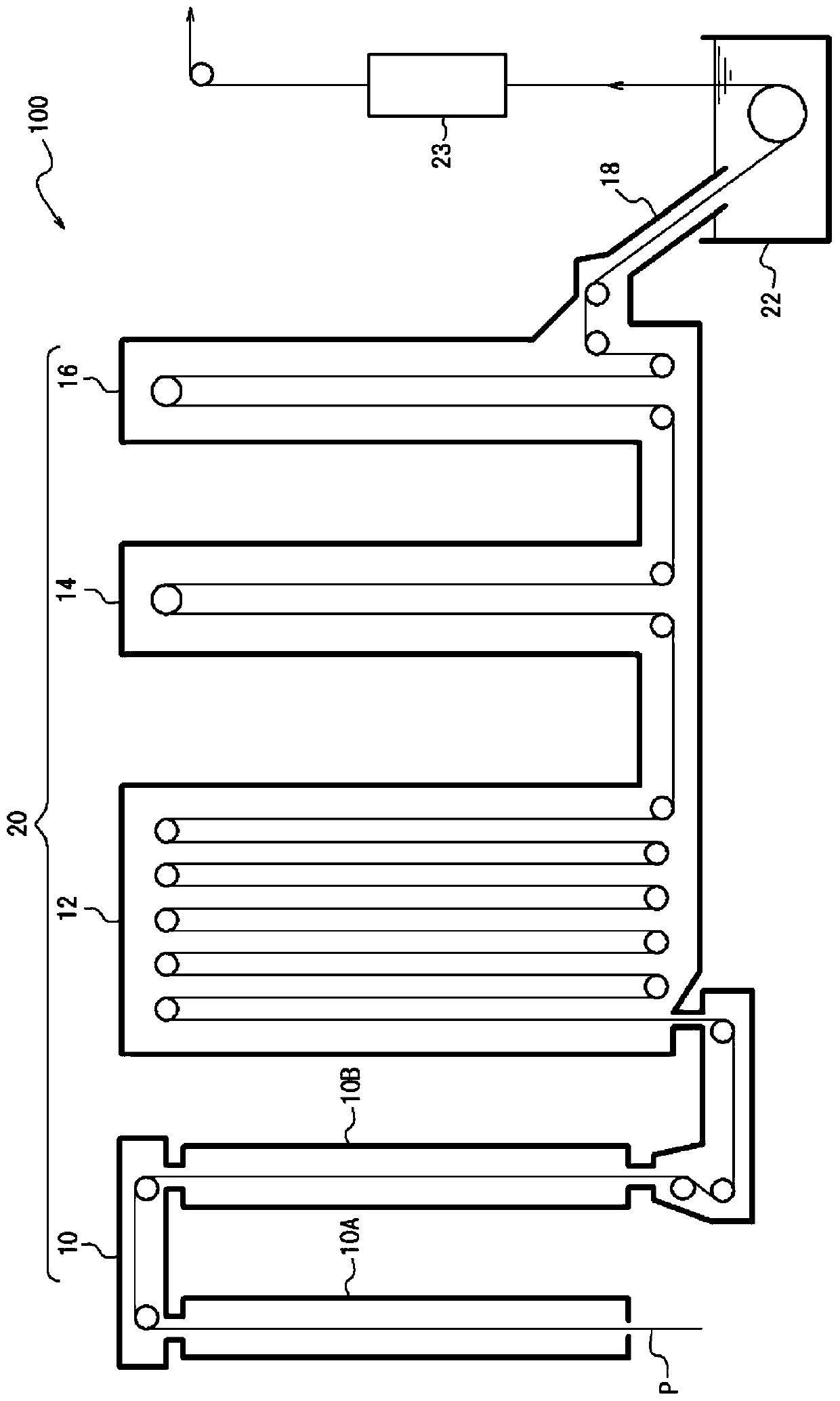

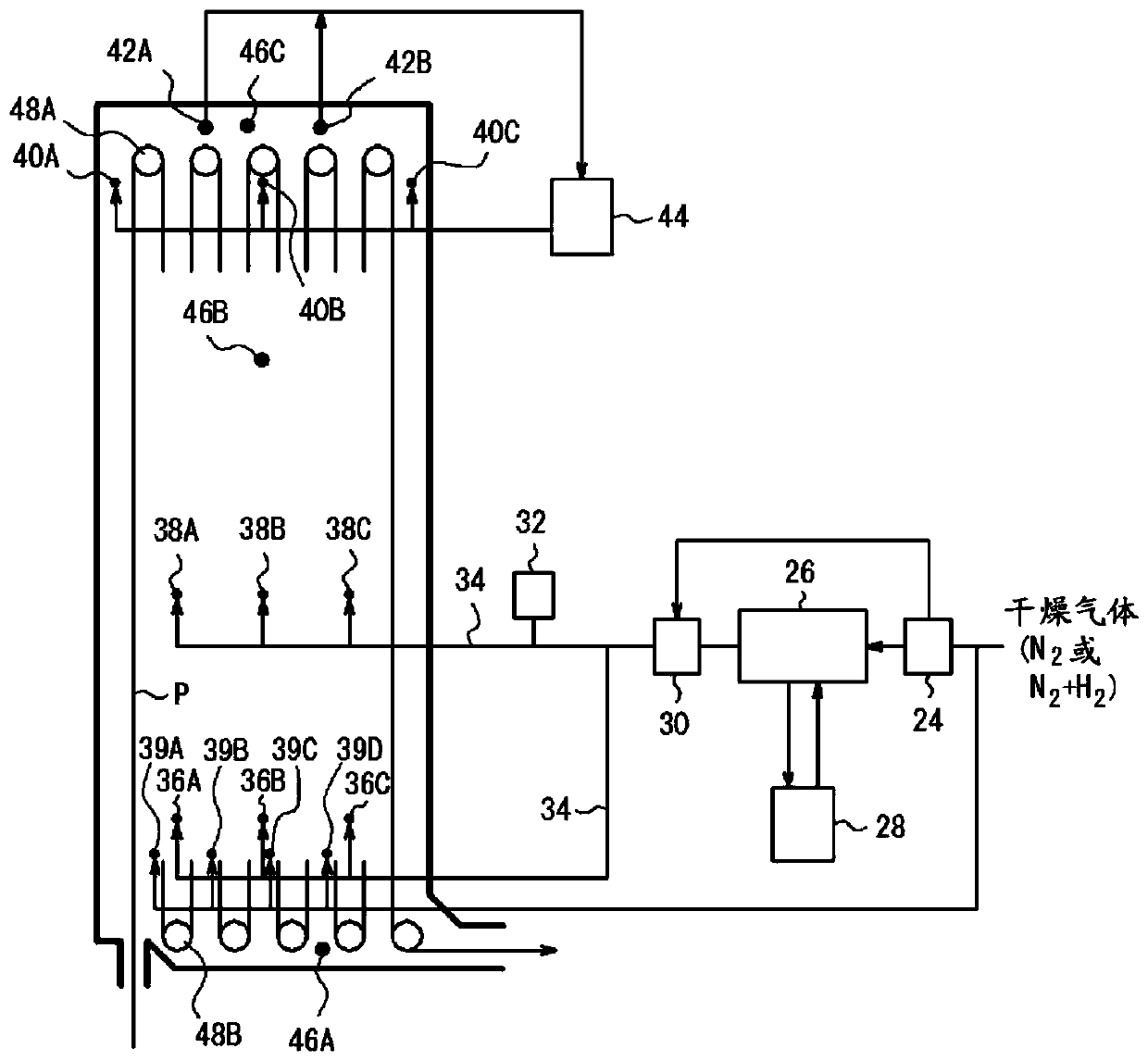

[0077] use figure 1 as well as figure 2 The continuous hot-dip galvanizing apparatus shown in Table 2 annealed steel strips having the composition shown in Table 1 under various annealing conditions shown in Table 2, and then applied hot-dip galvanizing and alloying treatments.

[0078] The second heating zone is set to DFF. The heating burners are divided into four groups (#1~#4), and the three groups (#1~#3) on the upstream side of the steel plate moving direction are used as oxidation burners, and the final zone (#4) is used as reduction burners. As for the nozzle, the excess air coefficients of the oxidation burner and the reduction burner were set to the values shown in Table 2. In addition, the length of each group in the steel plate conveyance direction was 4 m.

[0079] The soaking zone is set to a volume Vr of 700m 3 RT furnace. The average temperature Tr inside the soaking zone was set to the value shown in Table 2. As a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com