Manufacturing method for grinding wheel

A manufacturing method and grinding wheel technology, applied in the field of grinding wheel manufacturing, can solve the problems of short service life, poor internal density uniformity, and reduced grinding effect of electroplated diamond grinding wheels, and achieve good internal material uniformity, high fracture strength, and easy removal. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for manufacturing a grinding wheel of the present invention comprises the following steps: firstly, the metal powder mixture containing abrasives is used as a raw material, and an injection molding process is used to prepare a grinding wheel blank, and then the grinding wheel blank is sequentially subjected to a debonding process, a sintering process, and finally an electric Spark trimming into finished product

[0018] In this embodiment, the injection molding process is carried out using an injection molding machine, including injecting the metal powder mixture containing abrasives into the mold cavity under high temperature and high pressure to generate a grinding wheel blank, wherein the high temperature is 180°C ± 30°C, The high pressure is 70Mpa±25Mpa.

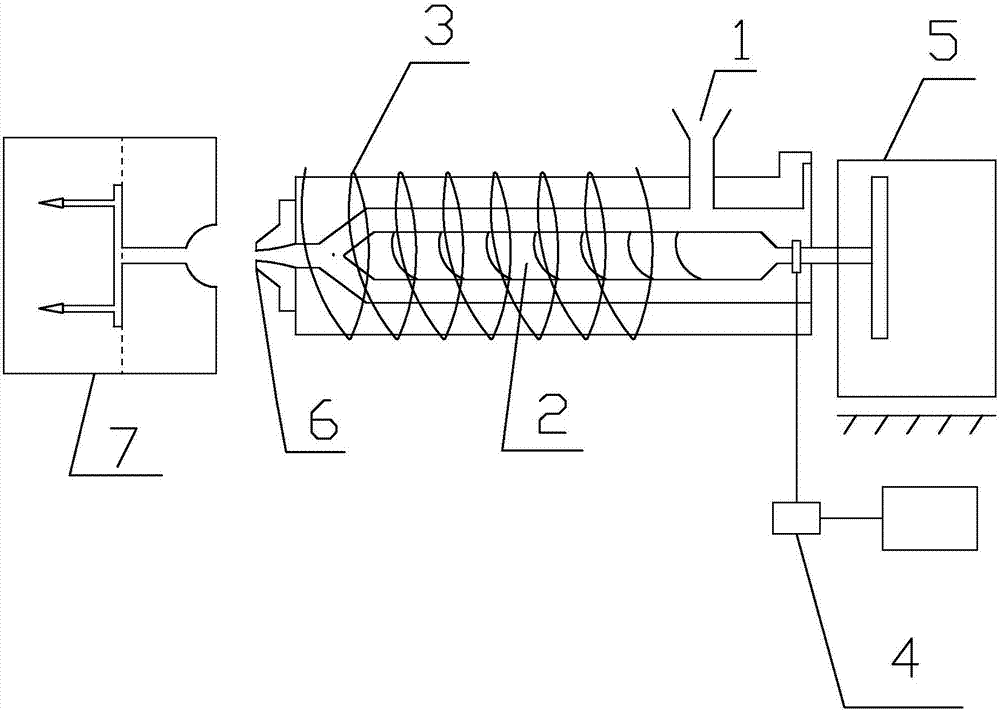

[0019] combine figure 1 As shown, the specific process of the injection molding process is as follows:

[0020] Put the metal powder mixture containing abrasive into the hopper 1, squeeze it through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com