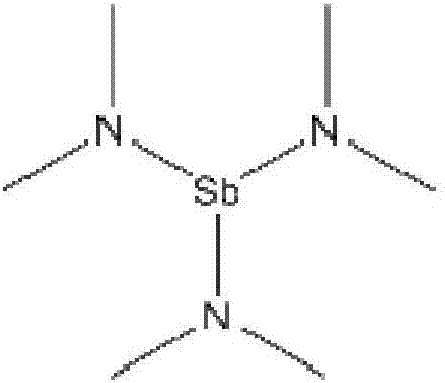

Synthesis method of tri(dimethylamino) antimony

A dimethylamino, synthetic method technology, applied in the field of triantimony synthesis, to achieve the effects of high yield, reduced synthesis cost and reaction toxicity, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Under an inert atmosphere, add 90g of dimethylamine and 300mL of n-hexane into a 2L reaction flask, keep the temperature of the system at about -10-10°C, and add 500mL of 2.5mol / L n-butyllithium n-hexane solution dropwise while stirring, After the dropwise addition was completed, the mixture was warmed to room temperature and kept stirring for 4 hours.

[0032] Dissolve 95g of antimony trichloride in 50mL of ether and 100mL of n-hexane, and add it dropwise to the above reaction system, keeping the temperature of the reaction system at about -30-10°C. Keep the system temperature not lower than 60°C and heat to reflux for 4 hours.

[0033] After the reaction was finished, the system was filtered, then the solvent was removed by distillation under normal pressure, and then the distillation under reduced pressure was collected to collect the distilled fraction, which was the target compound tris(dimethylamino)antimony, and 85g of the product was obtained, with a yield of 80...

Embodiment 2

[0035] Under an inert atmosphere, add 300g of dimethylamine and 1000mL of n-hexane into a 5L reaction flask, keep the temperature of the system at about -10-10°C, and add 1500mL of 2.5mol / L n-butyllithium n-hexane solution dropwise while stirring, After the dropwise addition was completed, the mixture was warmed to room temperature and kept stirring for 4 hours.

[0036] Dissolve 285g of antimony trichloride in 150mL of ether and 300mL of n-hexane, and add it dropwise to the above reaction system, keeping the temperature of the reaction system at about -30-10°C. Keep the system temperature not lower than 60°C and heat to reflux for 4 hours.

[0037] After the reaction was finished, the system was filtered, then the solvent was removed by distillation under normal pressure, and then the distillation under reduced pressure was collected to collect the distilled fraction, which was the target compound tris(dimethylamino)antimony, and 238g of the product was obtained with a yield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com