Construction method for wear-resistant floor

A construction method and ground technology, applied to floors, buildings, building structures, etc., can solve the problems of cumbersome procedures, labor and time consumption, etc.

Inactive Publication Date: 2017-09-01

JINGMEN CHUANGJIA MACHINERY TECH CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the main methods of wear-resistant ground construction in the field of construction engineering are: 1. Use a level to mark the surface elevation of the wear-resistant ground on the ground structure layer of the building and pile up a small lump of cement mortar to form an ash cake. The top elevation of the ash cake is the wear-resistant surface. The surface elevation of the ground is commonly known as the punching bar, and the thickness of the wear-resistant ground is generally 50 to 60 mm thick; 2. Pouring fine stone concrete, vibrating with a plate vibrator at the same time, leveling with a roller, and then constructing the wear-resistant ground surface; 3. , When the wear-resistant ground reaches a certain strength, use a cutting machine to cut the expansion joints, and pour the expansion joint ointment. The construction of the entire wear-resistant ground is completed. The process is cumbersome, labor-intensive and time-consuming

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] SUMMARY OF THE INVENTION The specific implementation manners of the present invention have been described in detail and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

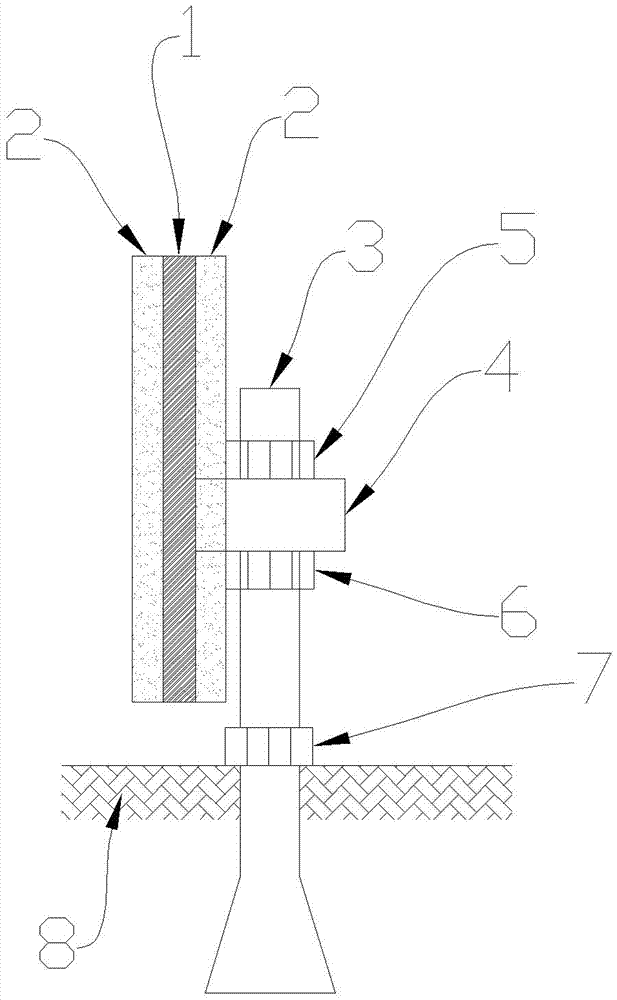

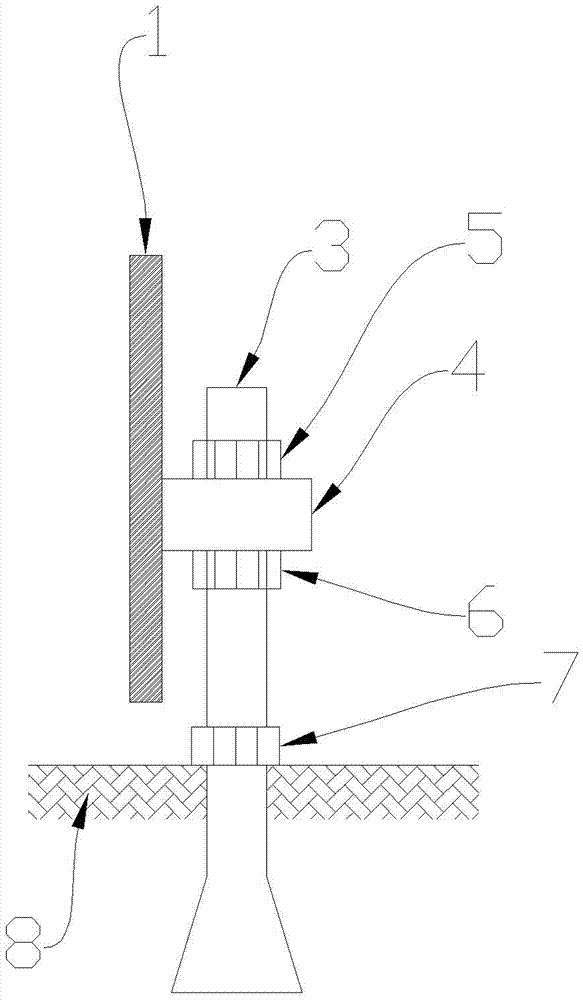

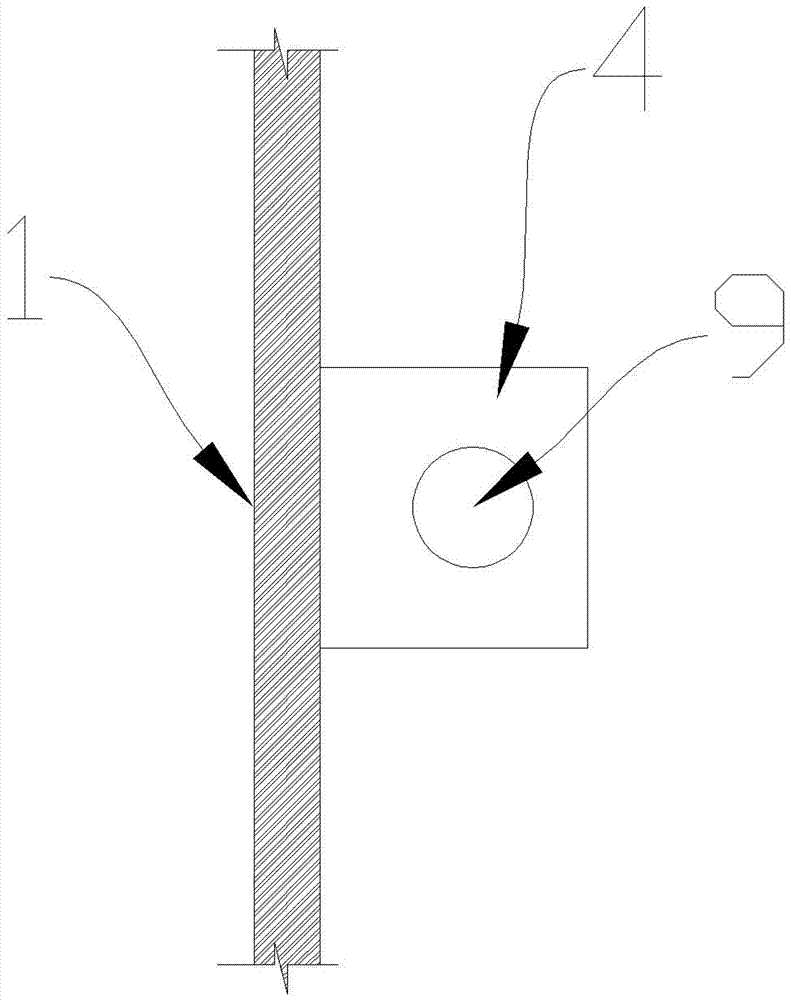

The invention discloses a construction method for a wear-resist floor. The construction method for the wear-resist floor is mainly used for wear-resistant floor construction in the field of constructional engineering, and can also be used for level finding construction of a building floor. The construction method does not need cutting expansion joints and pouring expansion joint ointment, and simplifies construction procedures. The construction method mainly comprises the steps that step one, position lines of the expansion joints are snapped on a structural layer of the building floor, holes are drilled at a certain distance along the position lines, expansion bolts are mounted, and fixing nuts B are screwed up; step two, adjusting nuts are screwed on the expansion bolts, expansion bolts penetrate through holes in the connecting plates, surface elevation of the wear-resistant floor is measured by using a level instrument, adjusting nuts are adjusted to enable the top elevation of steel plates to be consistent with the surface elevation of the wear-resistant floor, and then fixing nuts A are screwed up; and step three, fine aggregate concrete is poured, meanwhile a plate vibrator is utilized to conduct concrete vibrating, then the top surfaces of the steel plates serve as a datum of elevation, rollers are placed on the top surfaces of the steel plates to find level, finally a surface layer of the wear-resistant floor is constructed, and then construction of the whole wear-resistant floor is completed.

Description

technical field [0001] The invention is mainly used for wear-resistant ground construction in the field of construction engineering, and can also be used for floor leveling construction. Background technique [0002] At present, the main methods of wear-resistant ground construction in the field of construction engineering are: 1. Use a level to mark the surface elevation of the wear-resistant ground on the ground structure layer of the building and pile up a small lump of cement mortar to form an ash cake. The top elevation of the ash cake is the wear-resistant surface. The surface elevation of the ground is commonly known as the punching bar, and the thickness of the wear-resistant ground is generally 50 to 60 mm thick; 2. Pouring fine stone concrete, vibrating with a plate vibrator at the same time, leveling with a roller, and then constructing the wear-resistant ground surface; 3. , When the wear-resistant ground reaches a certain strength, use a cutting machine to cut t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04F15/12E04F15/14

CPCE04F15/12E04F15/142

Inventor 彭宝安

Owner JINGMEN CHUANGJIA MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com