Car frame traveling type shield tunnel wall post-grouting detection equipment

A technology of shield tunneling and grouting behind the wall, which is applied in the direction of tunnels, tunnel linings, measuring devices, etc., can solve the problems of little detection significance, poor detection stability, economic loss, etc., to improve detection stability, improve construction level, High degree of real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

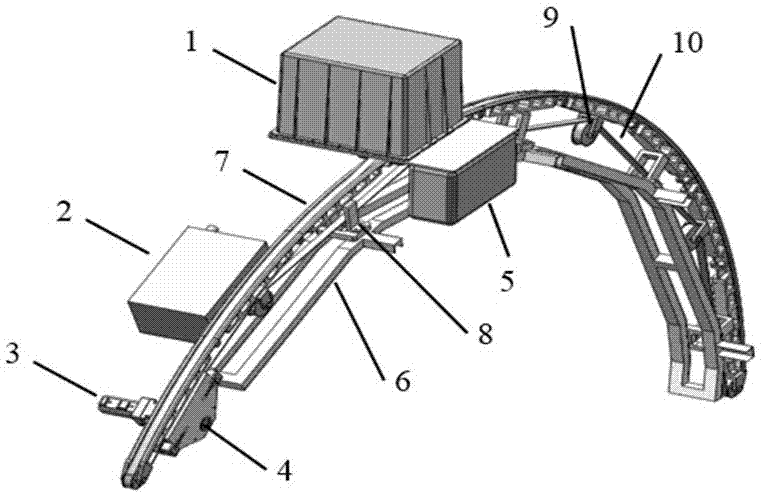

[0022] Embodiment 1; as figure 1 As shown, the device includes a ground penetrating radar 1 , a servo controller 2 , a drive motor and a reducer 3 , a transmission mechanism 4 , a radar acquisition box 5 , a bracket 6 , an assembled track 7 , a pulley 9 and a conveyor belt 10 . The ground penetrating radar 1 is connected to the conveyor belt 10 through the support plate, and the conveyor belt moves along a circle under the traction of the drive motor, the reducer 3 and the transmission mechanism 4, and the motion mode is controlled by the servo controller 2. The ground penetrating radar 1 acquires the radar signal and transmits it to the radar acquisition box 5 through the coaxial cable, and transmits it to the computer in the control room through the network cable for data analysis.

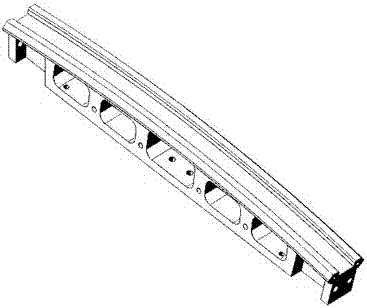

[0023] figure 2 It is the assembled track segment diagram of the present invention. According to the actual detection angle requirements, the number of stages required for the assembled track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com