Tunnel anti-seismic supporting system suitable for high seismic intensity area crossing faults

A technology based on intensity and area, applied in the field of tunnel anti-seismic support system, can solve the problems of increasing excavation area and project cost, increasing construction safety risk, prolonging tunnel construction period, etc., achieving good anti-seismic effect, improving anti-seismic performance, and absorbing seismic waves energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

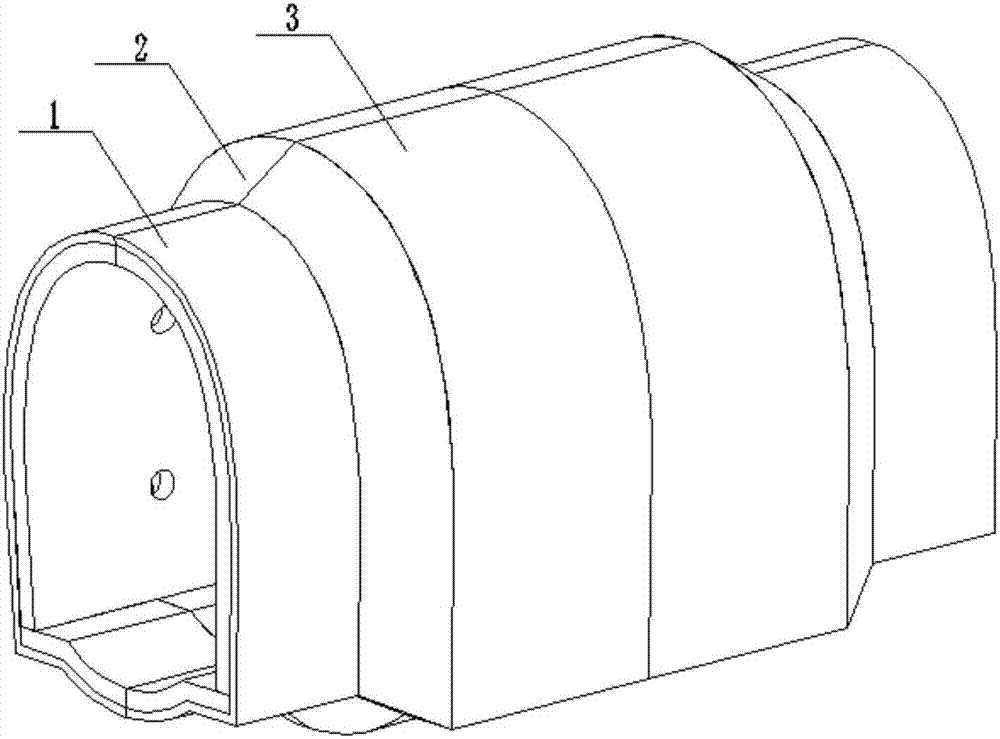

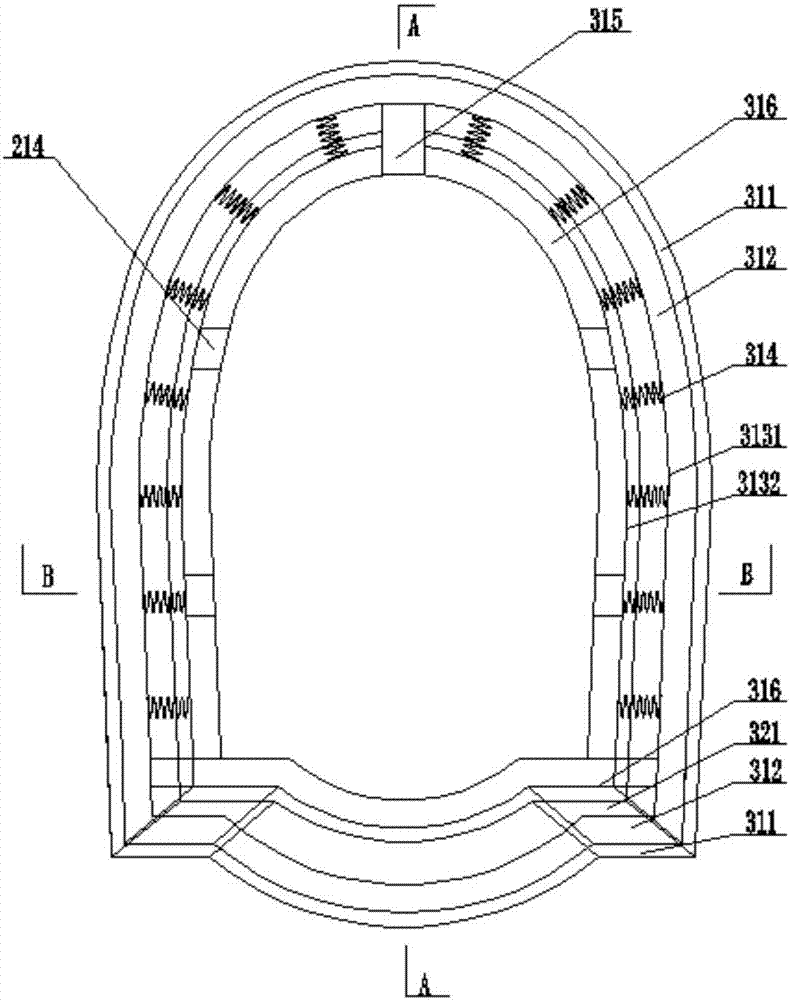

[0036] Example: such as figure 1 and figure 2 Shown: A seismic support system for tunnels crossing faults in high-intensity areas. The cross-section of the tunnel has a common support section and a seismically enlarged section. Tunnels can be cyclically combined to form multiple structures to meet the seismic requirements in different environmental conditions. Each tunnel seismic support system includes ordinary support section 1, grouting transition section 2 and seismic support section 3, ordinary support section 1 and seismic support section The support section 3 is connected by the grouting transition section 2 .

[0037] Such as Figure 4 and Figure 5 As shown, the ordinary support section 1 includes the primary support common layer 11 and the second lining common layer 12, the primary support common layer 11 and the second lining common layer 12 are sequentially arranged inside the surrounding rock, and the top arch and bottom arch support structure of the common se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com