Elastic support dry friction damper

A technology of dry friction damper and elastic support, which is applied in the direction of friction damper, spring/shock absorber, shock absorber, etc. It can solve the problems of large volume and unable to suppress the vibration of flexible rotors, and achieve small volume and light weight , control the effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

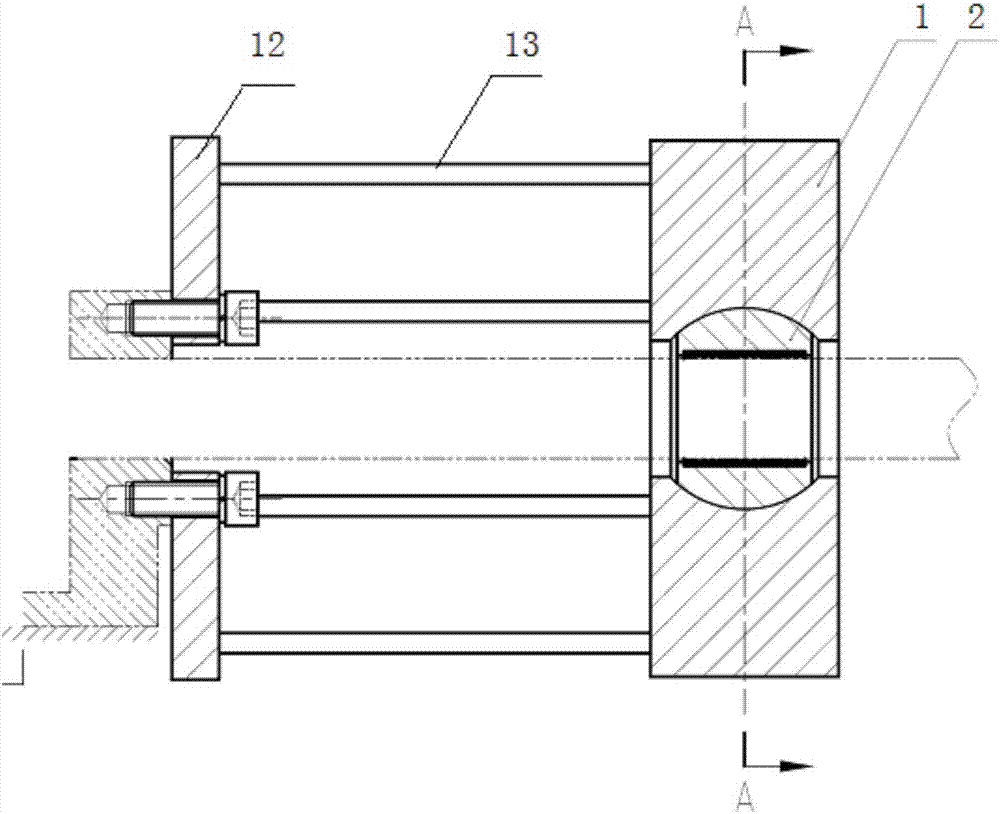

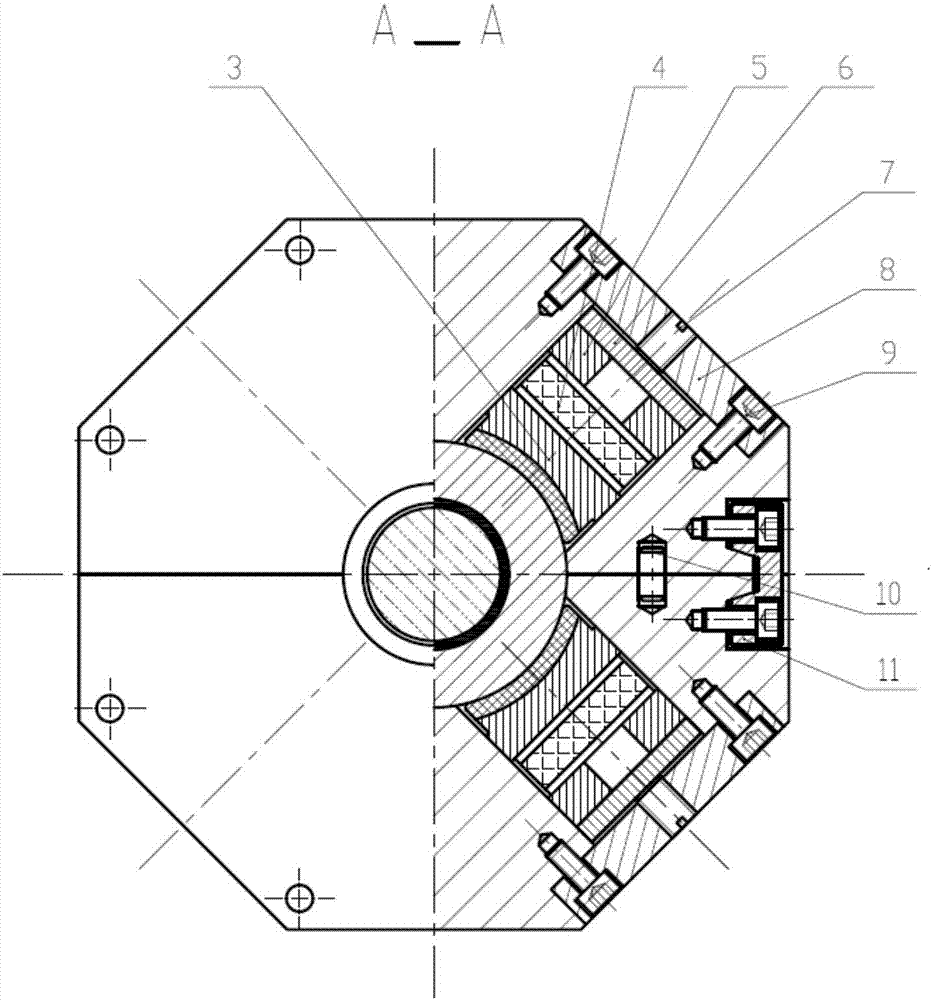

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings.

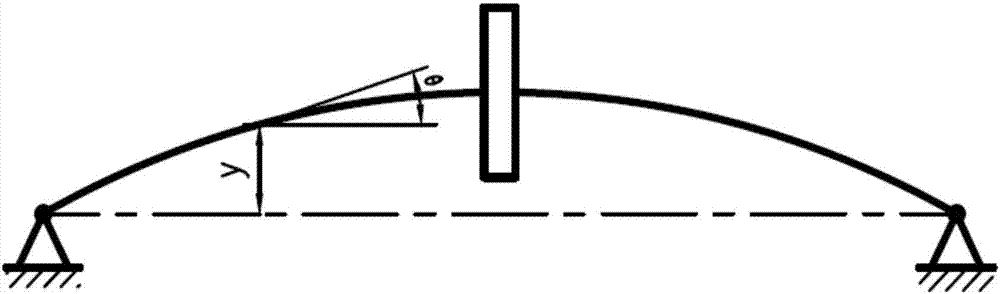

[0026] When working, the flexible rotor is in a bent state, and can be used as figure 1 The amplitude y and rotation angle θ are shown to describe the deformation state of the flexible rotor. For the convenience of description, the vibration of the flexible rotor in the y direction is described as the deflection part of the vibration, and the vibration part that produces a deviation from the axial direction θ is described as the deflection axial vibration. In order to suppress the vibration of the rotor, damping, stiffness or mass are usually added in the y direction, so the prior art cannot control the deflection of the axial vibration part of the flexible rotor.

[0027] The present invention adds a controllable dry friction damping force in the deflection direction, and simultaneously introduces a stiffness in the y direction, so as to simultaneously suppres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com