Liquid cold and hot exchanger for air-conditioning device

A technology for cooling heat exchangers and air conditioning equipment, applied in heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc., can solve problems such as pressure increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

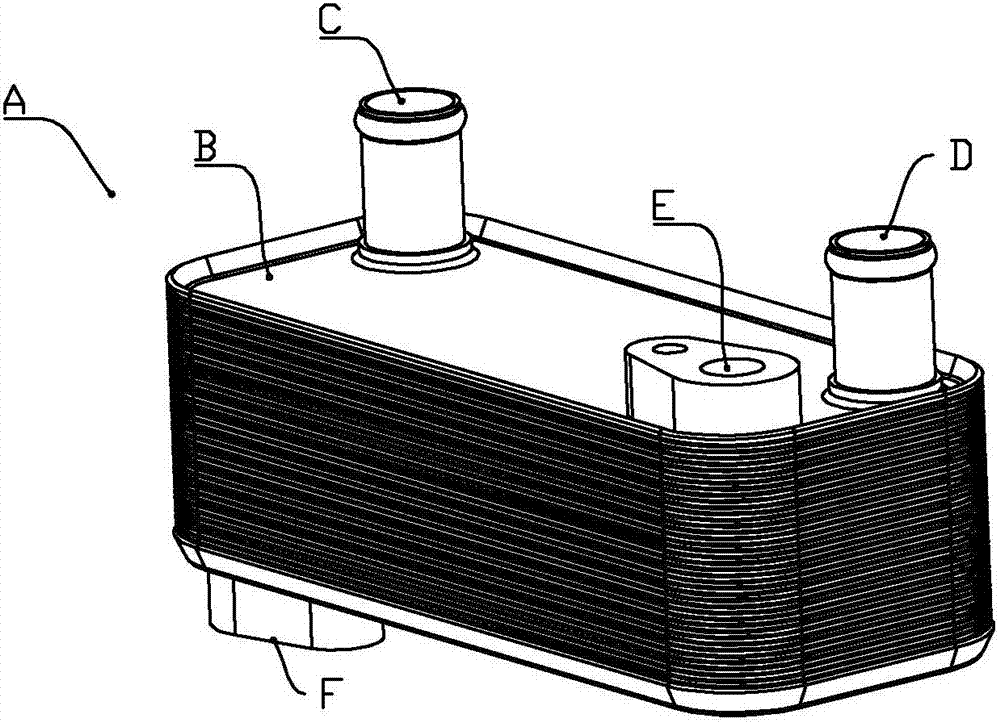

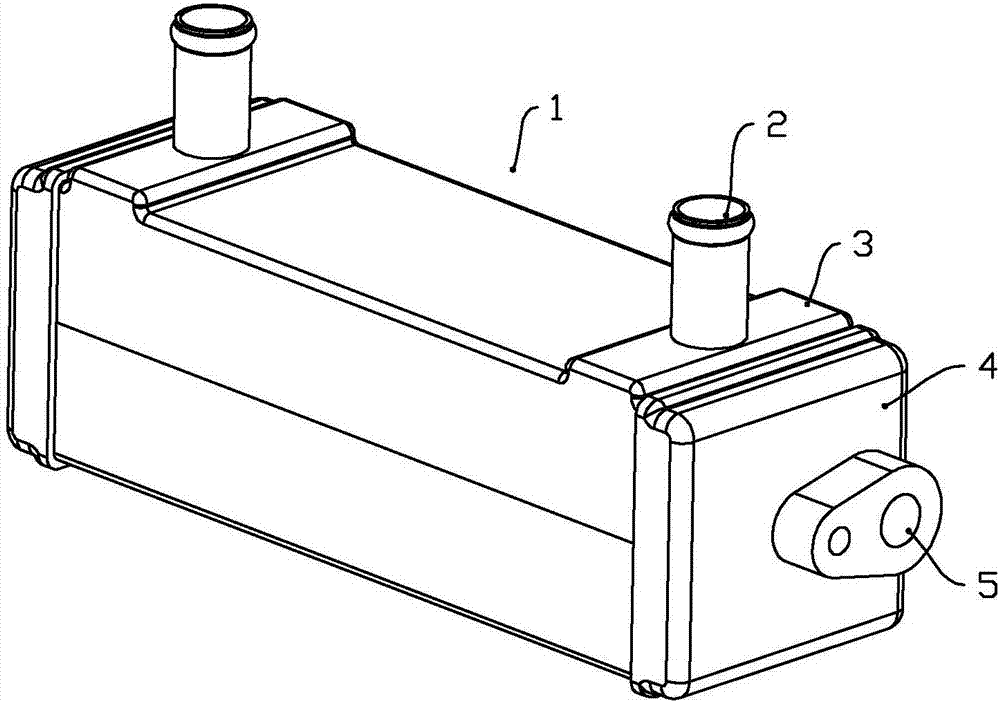

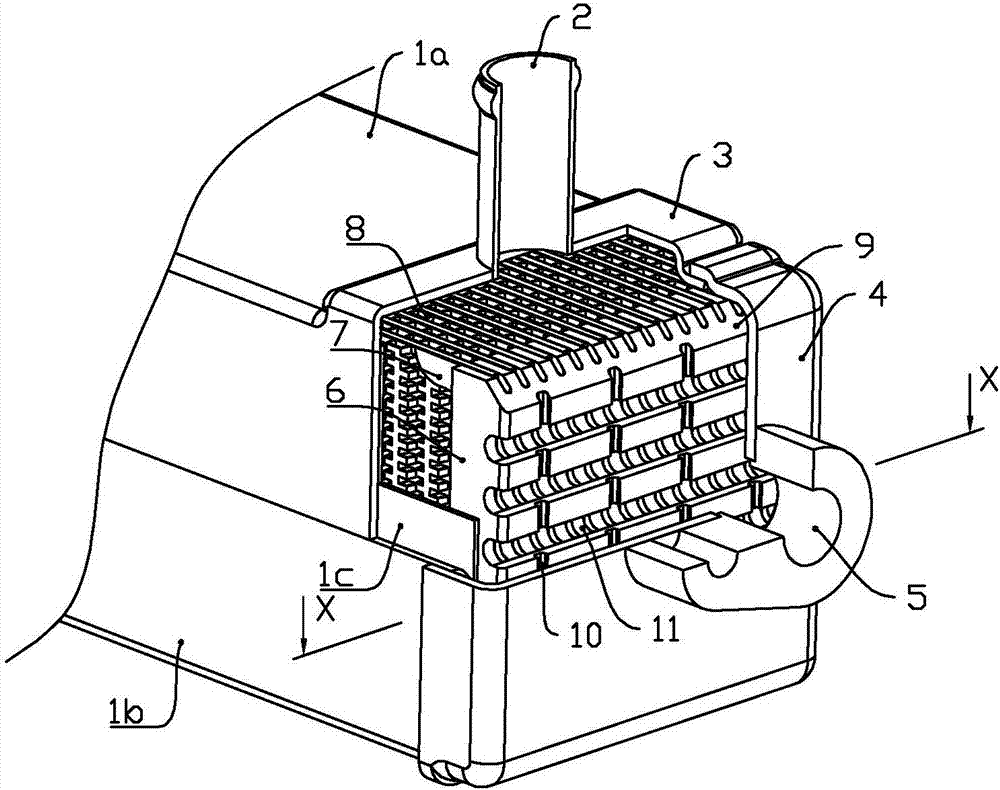

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-10 :

[0028] A liquid-cooled heat exchanger for air-conditioning equipment, comprising at least one row of flat tubes 7 and two main boards 6 arranged at both ends of the flat tubes 7, fins 8 are arranged between adjacent flat tubes 7, and the flat tubes 7 and fins 8 The core body of the cooler is formed. The flat tube 7 is inserted into the inner end surface of the main board 6, and the outer end surface of the main board 6 is distributed with a main flow channel 11 and an auxiliary flow channel 10 which are intersected and communicated with each other. The main flow channel 11 and the auxiliary flow channel 10 will The outer end surface of the main board 6 is divided into several small planes, and the main board 6 is provided with a collecting channel 12 connecting the flat tube 7 and the main flow channel 11; The small plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com