System display method of original austenite grain boundary of high-carbon high-alloy die steel

A technology of alloy die steel and austenite grain boundary, which is applied in the preparation of test samples, testing of moving fluid/granular solid, etc., can solve problems such as corrosion resistance and grain boundary difficulties, and achieve corrosion resistance and benefit Evaluation of grain size, beneficial effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

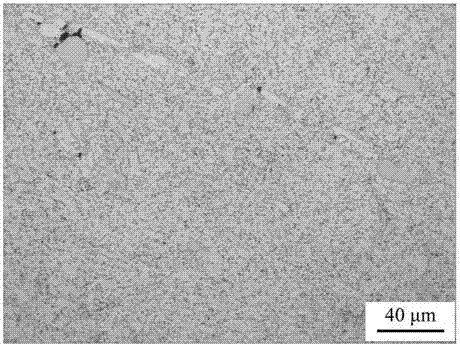

Embodiment 1

[0027] In the heat treatment process of high-carbon and high-alloy mold steel samples, the heating temperature is lower than 1100°C, and the holding time is within 400s, and the first metallographic etchant is selected;

[0028] The specific steps of the prior austenite grain boundary display method are as follows:

[0029] 1. Prepare the sample: Cut the sample into the required shape by wire cutting machine. If the sample is too small and not easy to clamp, it can be inlaid; the sample is polished with metallographic sandpaper of different particle sizes as abrasives, from coarse to fine , before changing the small-grained sandpaper each time, make the scratch direction on the polished surface of the sample consistent, and rotate it 90 degrees after the replacement. When the minimum particle size is 1000-1200 mesh, it can be polished by a polishing machine. The sample preparation is successful when the surface is smooth and without scratches;

[0030] 2. Preparation of the f...

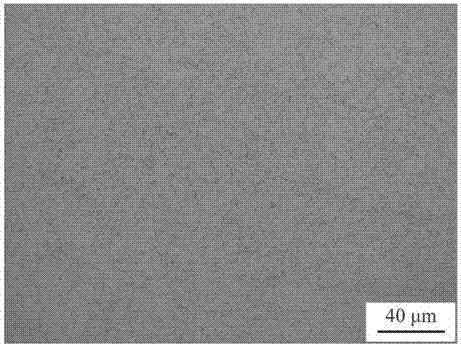

Embodiment 2

[0034] During the heat treatment process of high-carbon and high-alloy mold steel samples, the heating temperature exceeds 1100°C, the holding time exceeds 400s, and the second metallographic etchant is used;

[0035] The specific steps of the prior austenite grain boundary display method are as follows:

[0036] 1. Prepare the sample: Cut the sample into the required shape by wire cutting machine. If the sample is too small and not easy to clamp, it can be inlaid; the sample is polished with metallographic sandpaper of different particle sizes as abrasives, from coarse to fine , before changing the small-grained sandpaper each time, make the scratch direction on the polished surface of the sample consistent, and rotate it 90 degrees after the replacement. When the minimum particle size is 1000-1200 mesh, it can be polished by a polishing machine. The sample preparation is successful when the surface is smooth and without scratches;

[0037] 2. Preparation of the second metal...

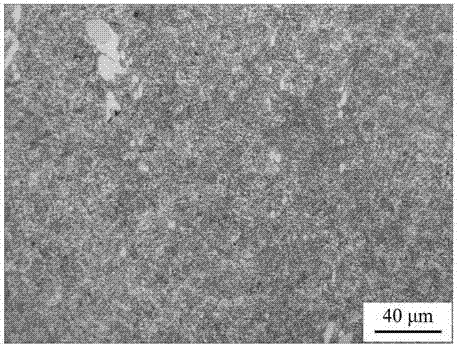

Embodiment 3

[0042] In the heat treatment process of high-carbon and high-alloy mold steel samples, the heating temperature is lower than 1100°C, and the holding time is within 400s, if the second metallographic etchant is used;

[0043] The specific steps of the prior austenite grain boundary display method are as follows:

[0044] 1. Prepare the sample: Cut the sample into the required shape by wire cutting machine. If the sample is too small and not easy to clamp, it can be inlaid; the sample is polished with metallographic sandpaper of different particle sizes as abrasives, from coarse to fine , before changing the small-grained sandpaper each time, make the scratch direction on the polished surface of the sample consistent, and rotate it 90 degrees after the replacement. When the minimum particle size is 1000-1200 mesh, it can be polished by a polishing machine. The sample preparation is successful when the surface is smooth and without scratches;

[0045] 2. Preparation of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com