A temperature-adjustable carbon crystal heating plate

A heating plate, carbon crystal technology, applied in electric heating devices, ohmic resistance heating, heating element materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

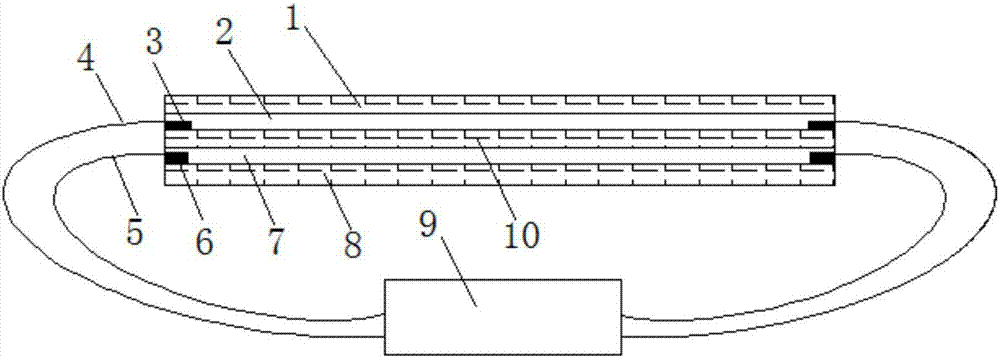

[0037] figure 1 A schematic diagram of a temperature-adjustable carbon crystal heating plate according to an embodiment of the present invention is shown.

[0038] Such as figure 1 As shown, the present invention provides a temperature-adjustable carbon crystal heating plate, which includes: a first resin layer 8, a first carbon crystal heating layer 7 is arranged on the first resin layer 8, and the first resin The two ends of the layer 8 are respectively welded with a first copper strip 6, the first copper strip 6 is covered by the first carbon crystal heating layer 7; a second resin layer 10, the second resin layer 10 is arranged on the first carbon crystal heating layer 7 On a carbon crystal heating layer 7, a second carbon crystal heating layer 2 is arranged on the second resin layer 10, and the two ends of the second resin layer 10 are respectively welded with second copper strips 3, and the second copper strips 3 is covered by the second carbon crystal heating layer 2;...

Embodiment 2

[0042] Such as figure 1 As shown, the specific structure and material of the temperature-adjustable carbon crystal heating plate of this implementation are all the same as in Example 1;

[0043] The specific ingredients of the heat generating slurry used in the first carbon crystal heating layer 7 and the second carbon crystal heating layer 2 include: in parts by mass, the slurry includes: 25 parts of graphite, 8 parts of nano-bamboo charcoal powder, 15 parts of ceramic propellant, 33 parts of silicate sol, TiO 2 13 parts of sol, 8 parts of low melting point glass powder, 3 parts of polycarboxylate ammonium salt ceramic dispersant, 1.5 parts of silane coupling agent, 1.5 parts of defoamer and 25 parts of water, and said defoamer is emulsified silicone oil; wherein , the ceramic emitter is Al 2 o 3 and MnO 2 Made by solid phase sintering, Al 2 o 3 and MnO 2 The mass ratio of the solid phase sintering is 1:1.5, the sintering temperature of the solid phase sintering is 900...

Embodiment 3

[0046] Such as figure 1 As shown, the specific structure and material of the temperature-adjustable carbon crystal heating plate of this implementation are all the same as in Example 1;

[0047] The specific ingredients of the heat generating slurry used in the first carbon crystal heating layer 7 and the second carbon crystal heating layer 2 include: in parts by mass, the slurry includes: 30 parts of graphite, 10 parts of nano-bamboo charcoal powder, 20 parts of ceramic propellant, 35 parts of silicate sol, TiO 2 15 parts of sol, 10 parts of low melting point glass powder, 4 parts of polycarboxylate ammonium salt ceramic dispersant, 2 parts of silane coupling agent, 2 parts of defoamer and 30 parts of water, and described defoamer is emulsified silicone oil; Wherein , the ceramic emitter is Al 2 o 3 and MnO 2 Made by solid phase sintering, Al 2 o 3 and MnO 2 The mass ratio of the solid phase sintering is 1:1.5, the sintering temperature of the solid phase sintering is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com